Different Types of Tape Measures

What is a Tape Measure and How Does it Work?

A tape measure is a flexible and portable device that is used to measure or capture the size or length of an object or distance. It consists of a flexible fiber, cloth, or metallic tape wound in a compact container. It has incremental markings, typically in feet and inches, and occasionally in metric units like meters and centimeters.

The most common tape measure lengths are 12 feet, 25 feet, and 100 feet, with longer tapes used for special applications like surveying. The tape is designed to be easily pulled out of the case and pulled back into it by means of a spring-loaded device.

The basic components of a tape measure are the case, in which the tape is wound up and which also acts as a handle to grasp the tool, and the tape, upon which measurement graduations are inscribed. Some tape measures have a locking device, in which the tape can be locked at a particular length, so that measurements can be made more conveniently without having to hold up the tape.

Popular Types of Tape Measures for Different Uses

For sewing and tailoring, the most ideal is cloth tape measures. These are flexible tapes most commonly made of a soft, flexible material like fiberglass or cloth that can bend around curves and contours to provide accurate body measurements. They come in various lengths, the most common being 60 inches or 150 cm.

The spring return or pocket tape is one of the most popular tape measures. The convenient instrument consists of a retractable metal tape in a strong plastic or metal housing. The spring action allows the tape to quickly retract into the housing once used. The tape measures of this type are a standard for do-it-yourself work, carpentry, and building construction and are available in 12 to 35-foot lengths.

Surveyor tapes are an extremely valuable instrument for large-scale land surveying and measurement. These very long tapes, which can be 300 feet or more, are constructed of very strong materials like steel or fiberglass. They are designed to be weather-resistant and to provide very precise measurements over very long distances, thereby making them extremely valuable for surveying, construction staking, and other civil engineering work.

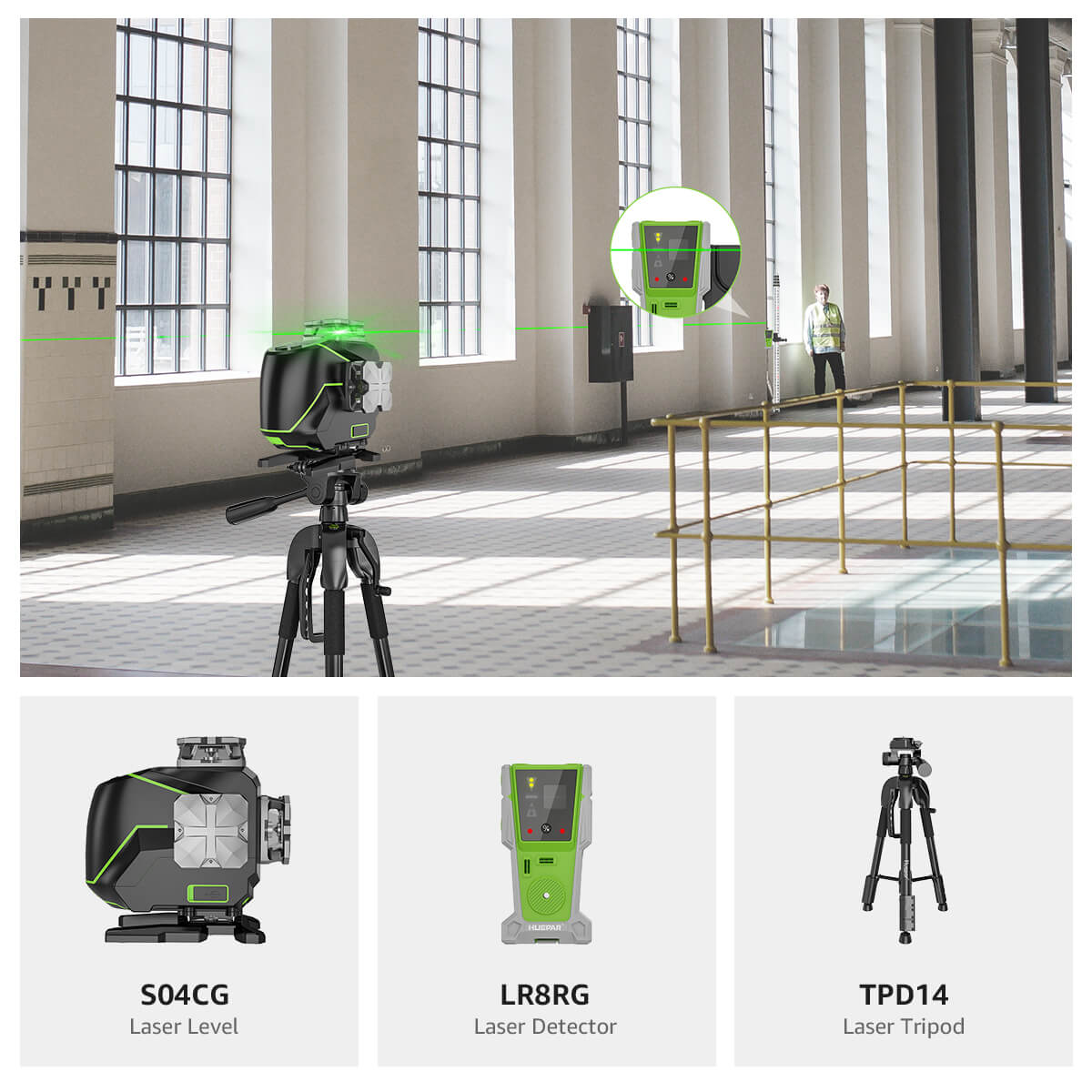

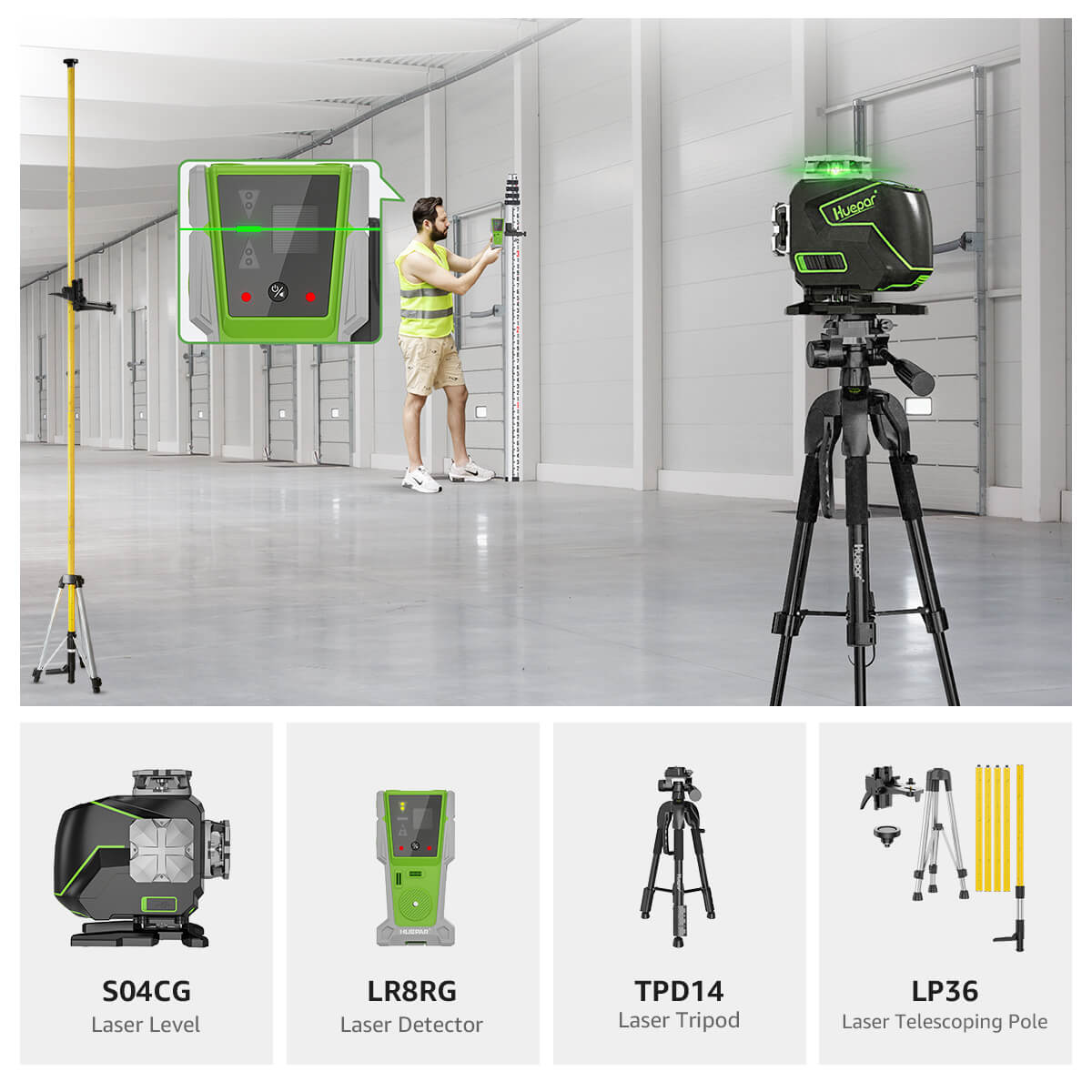

Digital or laser tape measures offer a modern and high-technology way of measuring. Laser tape measures make use of laser technology to measure distance precisely without the use of a physical tape. Just point the laser at the target surface and read the measurement from the integrated digital display. Laser tape measures are simple to use, convenient, and there is no room for misreading conventional tape markings. Laser tape measures are also suitable for measuring hard-to-reach points or over obstructions, which makes it a great measuring tool for professionals and weekend warriors.

Important Features to Look for in a Tape Measure

When selecting a tape measure, there are some key features to consider that will make it more helpful and durable.

One such feature that is helpful is a magnetic end, where the tape measure will stick temporarily to metal objects, allowing one to measure by themselves. This is particularly handy when measuring on metal frames or in cramped spaces.

The second aspect that is required is a blade lock mechanism. This allows the user to extend the tape to the desired length and lock it so that it will not retract. This is particularly helpful when measurements are being taken that need to be taken with both hands, such as measuring widths or large items.

For individuals who work in wet or damp environments, a rust-resistant or water-resistant tape measure is needed. These tape measures are designed to withstand exposure to water, rot, and corrosion, but still provide accurate measurements.

Standout length, or the maximum length the tape can extend, is also something to consider. Greater standout lengths are best for bigger measurements, such as in construction or surveying applications, and shorter lengths may be more appropriate for smaller projects or in more confined spaces.

Finally, bold and clear marking on the tape measure blade can do much to improve visibility and measurement reading accuracy. Select tape measures with high-contrast markings that are legible even from a distance or under poor lighting conditions.

Tape Measure Materials and Construction

Tape measures are constructed to be hardy and durable tools, and therefore they are able to withstand the rigors of most worksites and environments. The construction materials used to build them contribute significantly to defining their overall performance and durability.

The case, which houses the retractable tape blade, is typically made of plastic or metal. Plastic cases are cheap and lightweight and are a popular choice among homeowners and do-it-yourselfers. Metal cases are stronger and shock-resistant, however, and are ideal for abusive professional use in construction and industrial settings. Rubber grips or overmolded cases are also available, providing a firm and comfortable grip, even in damp or slippery conditions.

The blade itself is the breadwinner of the tape measure, and the material used to make it is not different. Steel tape blades are the most common, bringing strength and resilience in resistance to stretching or breaking when pulled tight. Steel, however, is susceptible to rust and corrosion, which can affect the accuracy of measurements over time. To mitigate this, most manufacturers employ protective coatings or the use of stainless steel for higher corrosion resistance.

For applications requiring more tape length, such as surveying or building, fiberglass tape blades are typically used. Fiberglass is light, resistant to stretching, and pliable, which makes it ideal to measure across long distances with no errors. Fiberglass tapes are also resistant to moisture and temperature variations, which allows them to give precise and repeat measurements in different conditions.

In addition to materials, tape measure design and construction also affect ergonomics and performance. Impact-resistant cases and blade-reinforced openings are common in most tape measures and can withstand dropping or being hit on the construction site. Contoured cases and non-slip grips can also improve comfort and control for extended use, reducing fatigue and improving accuracy.

Choosing the Right Tape Measure for the Job

When you select a tape measure, consider your specific measuring needs, where you will be applying it, and the degree of accuracy. There are several types of tape measures for different purposes, from sewing and crafts to construction and surveying.

For short measurements around the house or office, a pocket or spring-return tape measure will usually do the trick. These handy and simple tools usually extend to 25 feet and are ideal for measuring room sizes, furniture, or window sizes.

If you require measuring longer distances, say for outdoor purposes or for building, then a longer tape measure is ideal. Surveyor tapes of 100 feet or more are ideal for measuring long distances such as building plots, landscaping, or boundaries.

Accuracy is also a consideration. For precise measurements, find tape measures with easy-to-read, clear markings and a sturdy construction to withstand stretching or bending. Digital tape measures, using laser technology, can provide highly accurate readings and are particularly useful for contractors, architects, or engineers who require precise dimensions.

Environmental factors can also affect your choice of tape measure. In wet or humid conditions, a rust-resistant tape measure made from stainless steel or fiberglass is what you need. Magnetic tape measures are handy because they stick to metal surfaces, so they are an excellent option for HVAC specialists, plumbers, or electricians who handle metal ductwork or pipes.

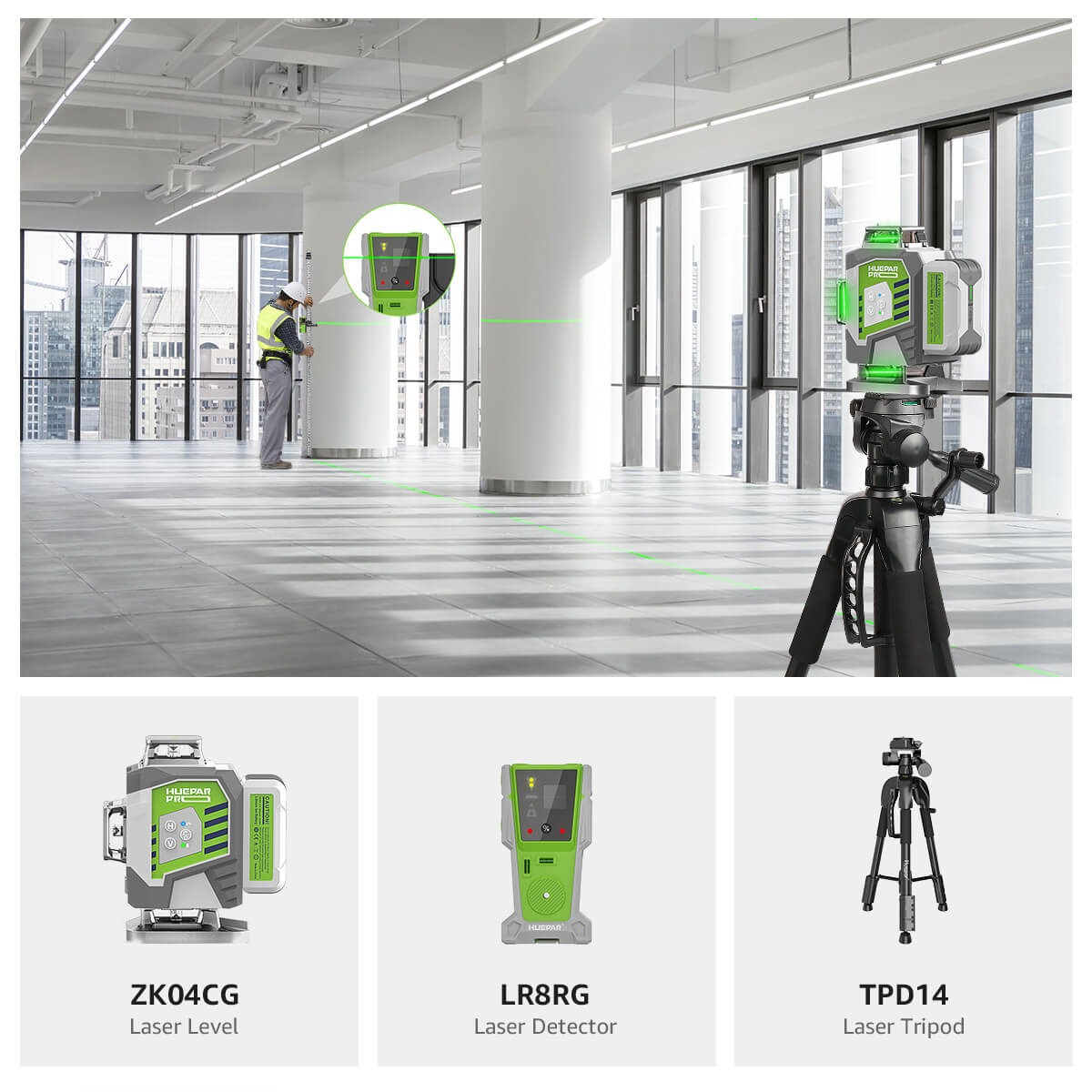

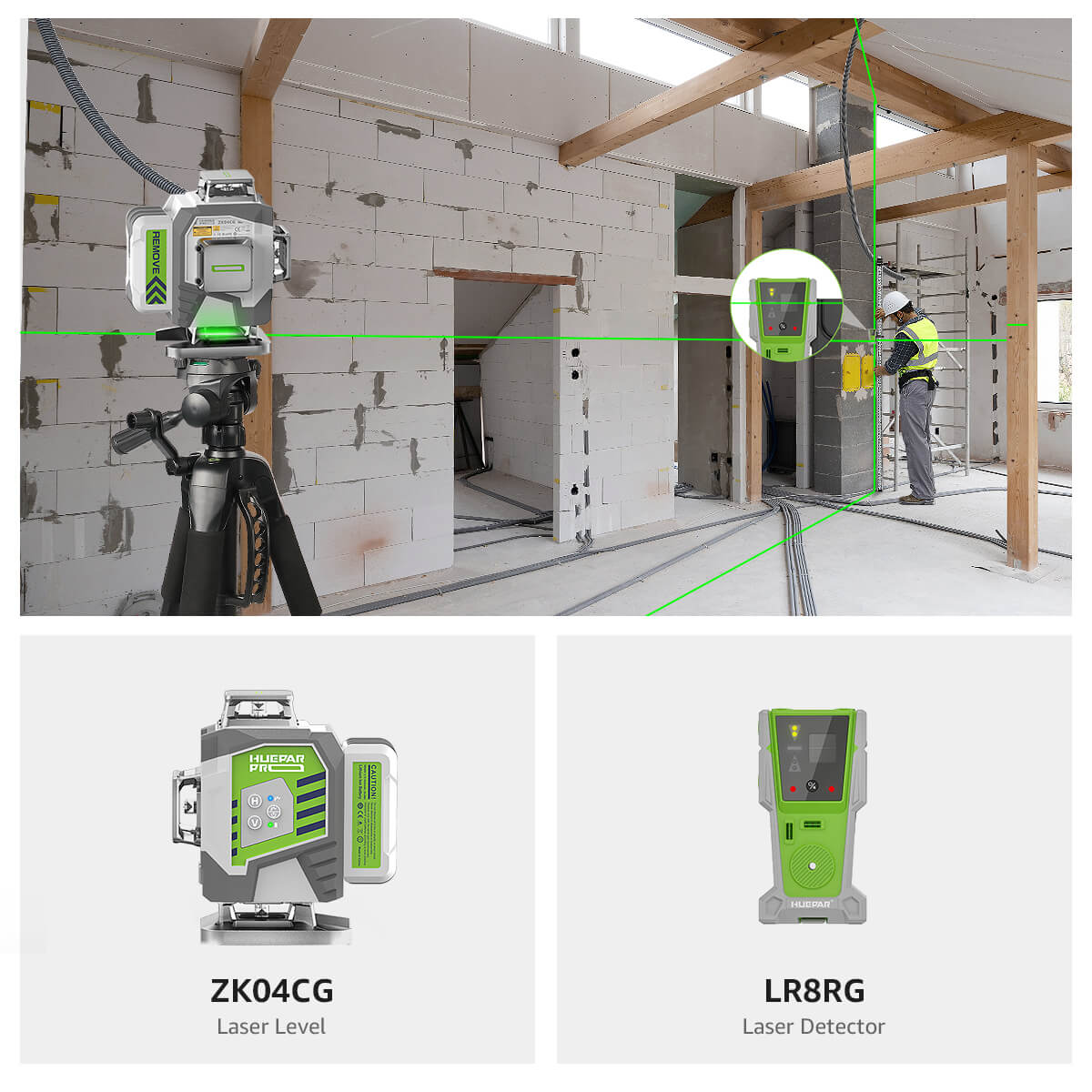

Top brand like Huepar is known for producing excellent laser levels and tape measures that offer durability, precision, and convenience features like clear markings, tough cases, and ergonomic grips.

Care and use are needed to prolong your tape measure's lifespan. Never let the tape snap back into the case, and wind it back slowly, because constant impact can damage it over time. Store your tape measure in a dry place and do not leave it in the sunlight or expose it to harsh chemicals. Regular cleaning and maintenance can also ensure accurate measurements and prolong the lifespan of the tool.