Choosing a Rotary Laser Level for Both Indoor & Outdoor Use

What is a Rotary Laser Level?

A rotary laser level is a high-end tool that sends moving laser beam onto vertical or horizontal plane to give level of reference for leveling work or alignment work. As compared to traditional bubble levels that work on visual inspection of liquid-filled vial, rotary laser levels offer more performance, versatility, and precision for indoor or field work.

Middle of rotary laser level is laser diode that sends focused laser beam that is routed through moving head that spins at predetermined speed to cast laser beam in plane of laser beam of 360° continuously. Spinning laser beam produces for exceptionally discernible level of reference traceable by third-party laser sensor or laser receiver.

One of biggest advantages of rotary laser levels is that level of reference is projected at far distances, thus ideal for large work like building work, landscape work, or survey work. Traditional bubble levels have limitations in their work capacity and need for view in-line while rotary laser levels project level of reference through obstructions or around edges to improve significantly in performance and level of correctness.

Self-level feature in majority of rotary laser levels offers automatic leveling of laser beam to level of plane within predetermined limits of inclination. Through these features, leveling by hand is not necessary thus consistent level of correctness even on uneven terrain or if tool has been bumped or shifted in work by accident while in work.

How to Choose a Rotary Laser Level

When selecting a rotary laser level for indoor and outdoor use, there are several key factors to consider:

Room Size and Line Visibility: For indoor spaces that are not so large, a multi-line output rotary laser level offers good visibility and coverage. Outdoor work typically requires more power in a rotary laser that has good visibility of a clear, bright beam at distances far from where it is placed.

Self-Leveling vs Manual Leveling: Outdoor work on uneven terrain requires automatic leveling capability in a rotary laser that achieves leveling on its own. Manually leveling laser requires more initial setup but can work for solid indoor jobs.

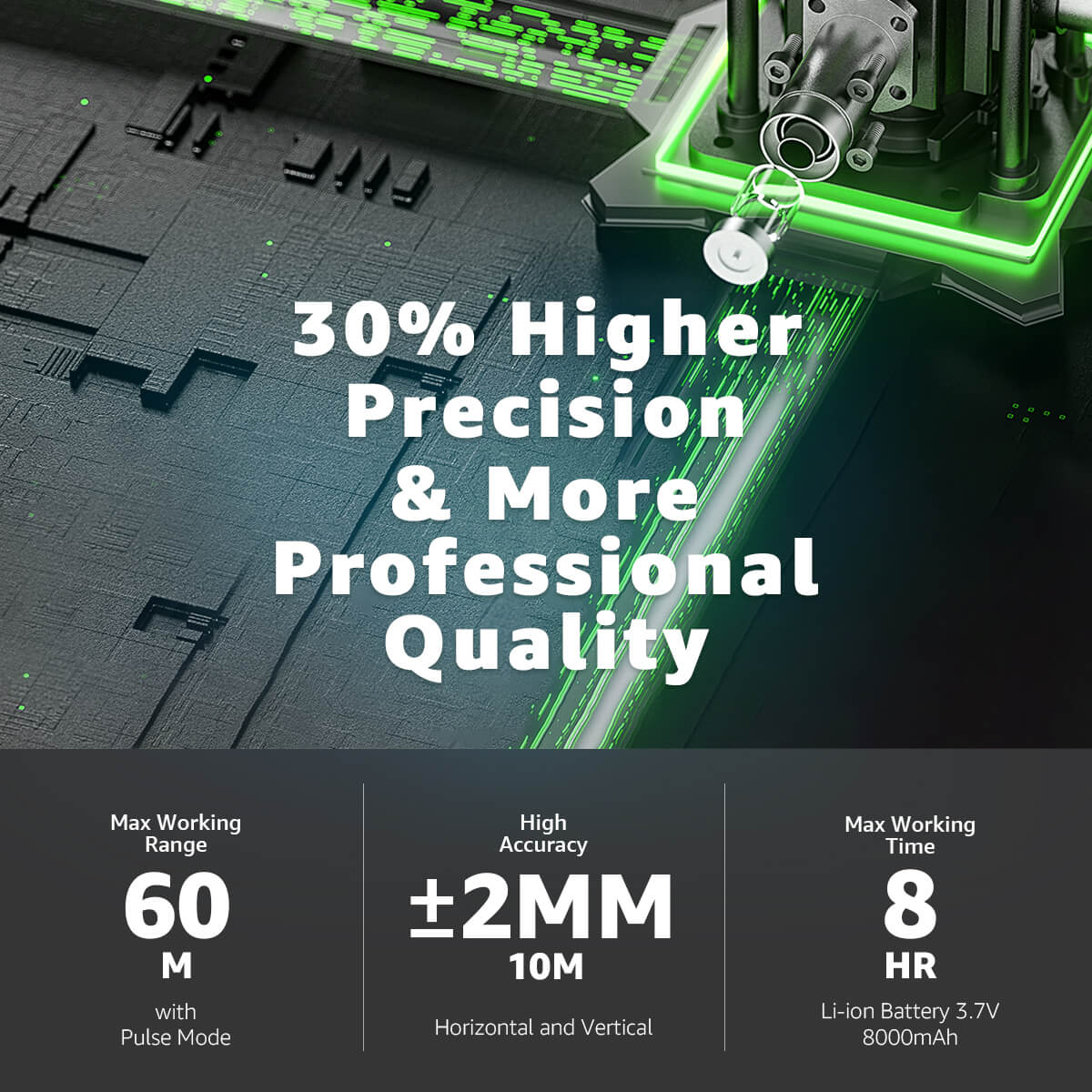

Accuracy and Precision: Various jobs require varying levels of accuracy. Construction work and leveling require higher accuracy while rough layouts might not require extreme accuracy. Consider how much tolerance is needed for your work.

Rotation Speed (RPM): Higher RPMs create more noticeable, solid lines that work for jobs in the field or at far distances. Low RPMs work for indoor spaces but might cause flicker for indoor work.

Durability and Weather Resistance: Outdoor jobs require rugged, weather-tight encasements for their laser level to endure jobsite conditions. Models for indoor work alone might be more weather-tight but not so rugged or weather-tight.

Considering room size, terrain conditions, accuracy requirements, and operating conditions, you can make good choices for selecting that perfect rotary laser level for trouble-free indoor work or outdoor leveling work or alignment work or layouts.

Rotary Lasers for Outdoor Projects

Outdoor work on uneven terrain with higher distances to project requires that special kind of power in their rotary laser level that has good visibility of clear beam at far distances from where it is placed on uneven terrain.

The key benefits of using a rotary laser outdoors include:

Long Range Capabilities: Quality laser rotary has projected beam to approximately 2000 feet or more in diameter, so these are suitable for expansive work spaces or large areas like landscaped areas or work spaces or on farm lands.

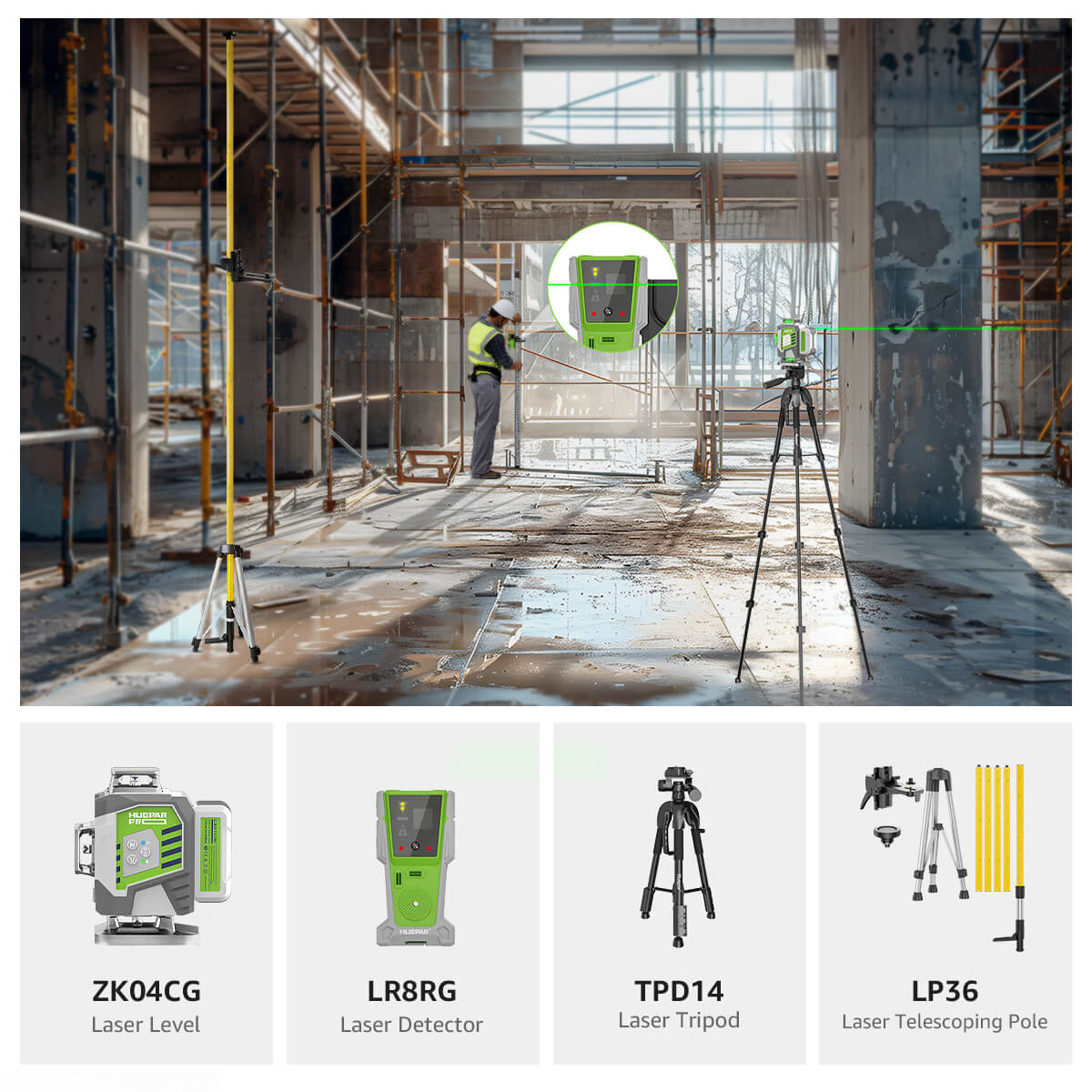

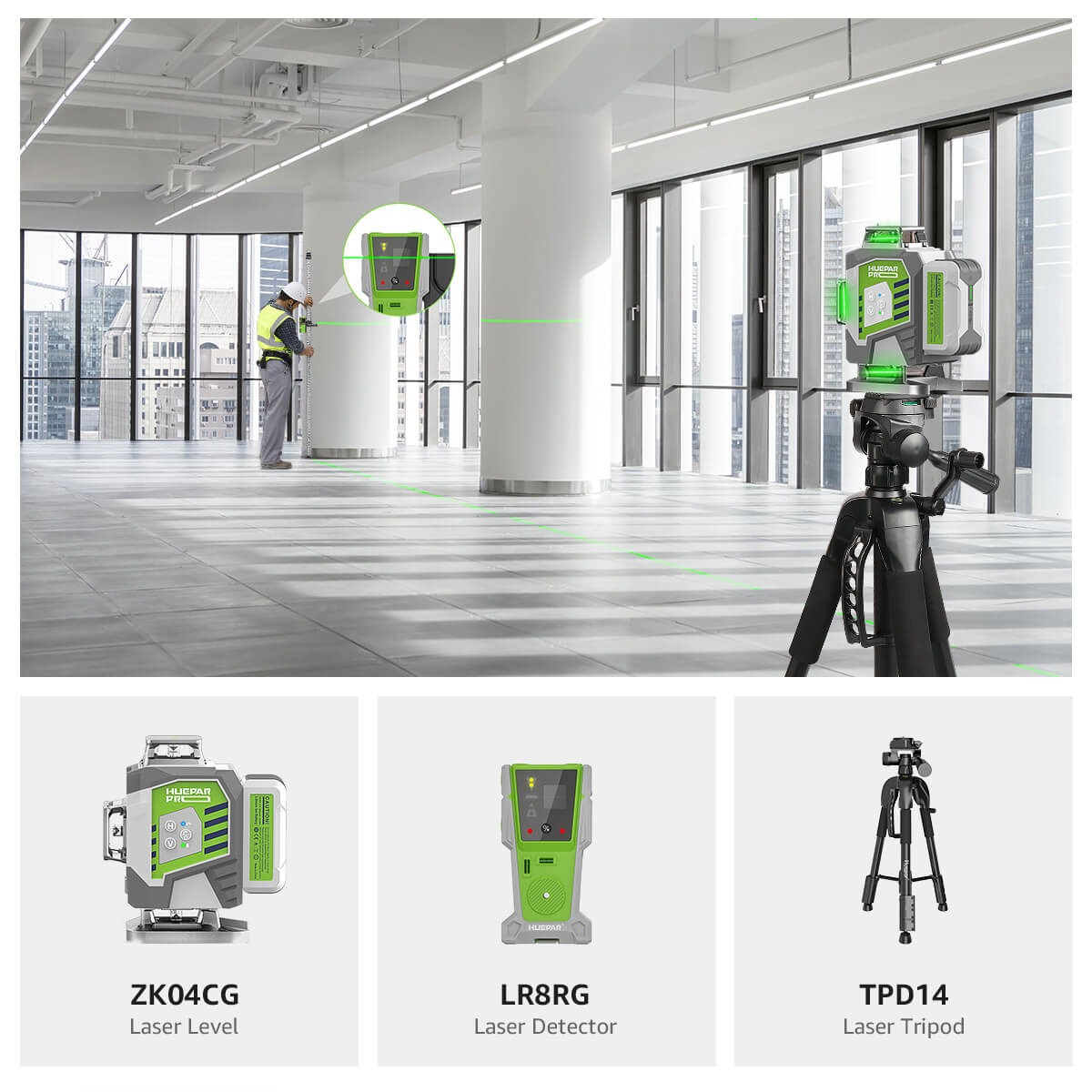

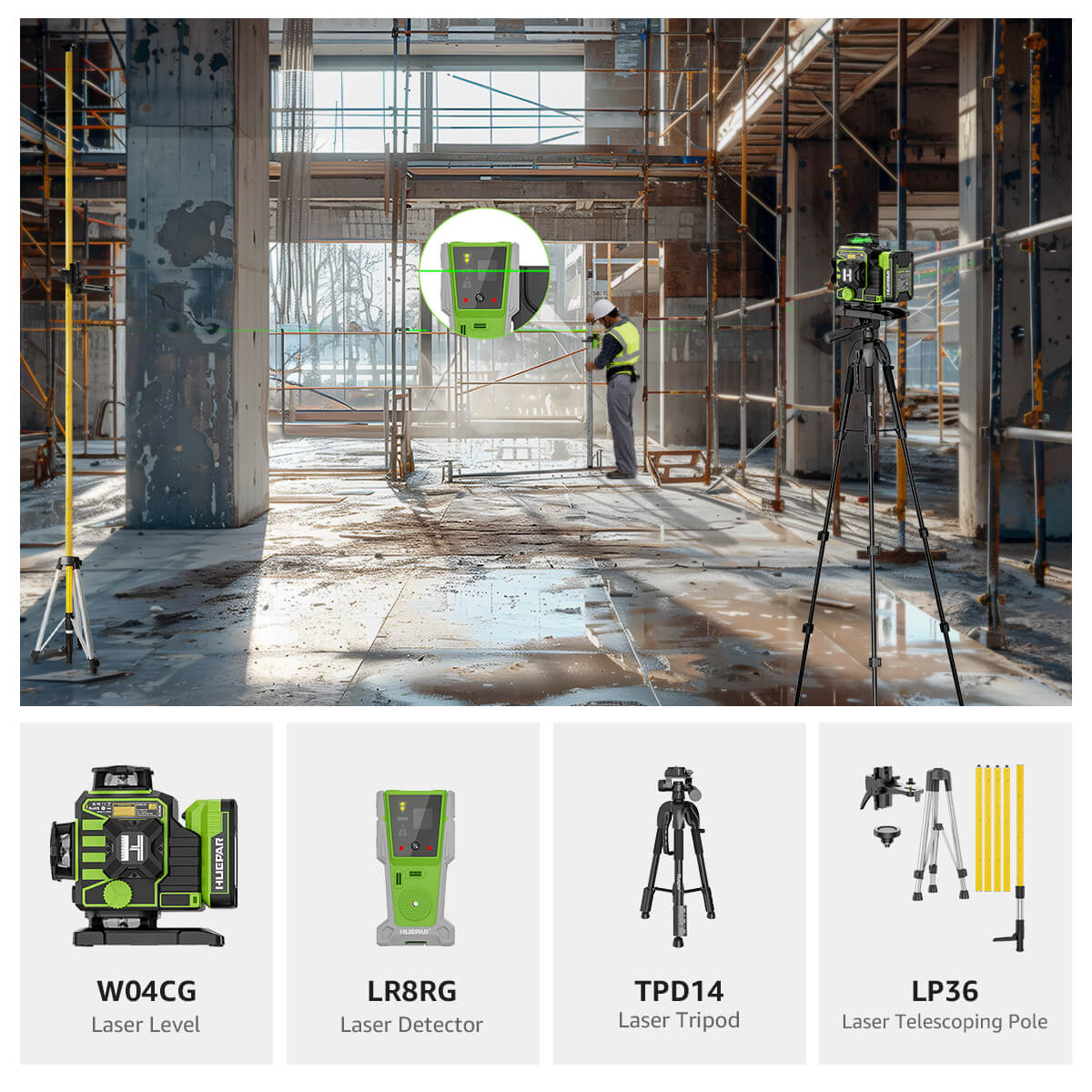

Tripod Stability: Having robust tripod to mount the rotary laser offers excellent balance even on uneven terrain. This offers precise consistent laser lines on sloping terrain or on distances where even tiny changes in level throw off readings.

Self-Leveling Function: Most of these field laser rotary have automatic self-leveling that achieves perfectly level horizontal or plumb vertical lines in quick way. This is faster than leveling by hand and makes level checks at quick glancing easy to verify at all points of measurement.

Rugged Design: Professional laser for field working has rugged weather-sealed encasements that protects components from moisture, dust or damage from drops or bump on work environment.

To get suitable laser for work in field, get ones with high RPM that project viewable laser beam even in sunlight conditions. Outdoor far-away display receivers further contribute in having crews accurately identify laser reference even through obstructions or far from laser placement points.

Consider Rotary Laser Speed and Visibility Range

When choosing field or indoor work laser level for field or indoor work, consider how far laser beam has to travel in order to have how much RPM to have for visibility through that far. For indoor work in small indoor rooms, low RPM laser would make it through because laser beam has not much far to travel through. For larger indoor rooms or field or field work or field work in general though, higher RPM laser would work for visibility through larger distances.

Visibility of laser beam is further influenced by RPM of laser level. At low RPMs of around 300-600 RPM or so, more of focused beam is emitted that is easy to see at near distances but may not at larger distances. At higher RPMs of around 600-1000 RPM or more, more of dispersed beam is emitted that is more easy to see at larger distances but at higher RPMs may have more of sacrifice of preciseness at near distances.

It may make sense to consider further that higher RPMs have more of larger fan angle to their beam that results in more space coverage but at some sacrifice of preciseness at near distances. At low RPMs of laser level output, more preciseness for near work may be attained but more repositioning would have to take place for larger jobs.

Common Applications for Rotary Laser Levels

Construction Contractors

Rotary laser levels are indispensable for commercial and residential construction contractors on large jobs. They provide for exceptionally precise leveling at extreme distances, which is vital to correctly establish foundation points, set floors of poured concrete, align ceilings and walls, and accurately calculate cut and fill quantities. The combination of self-leveling capability with a rotary head makes for easy level setup even on rough jobsites in the field.

Builders

Residential builders of houses use rotary laser levels to plumb and align walls in record time with laser-sharp accuracy. This guarantees perfectly straight and square framing that avoids complications later in installing drywall, floors, cabinets and fixtures. Rotaries work equally well in indoor or outdoor work spaces for maximum versatility for builders.

Deck Builders

Constructing decks off of or freestanding from the house or even freestanding structures themselves, deck builders count on rotary laser levels to accurately set footings and posts at proper elevations to avoid sloping complications and improper drainage complications. They can methodically work across rough terrain with uneven jobsites in their laser level.

Farmers

On farm operations, agricultural growers take advantage of their farm-grade laser level to level their lands for precise leveling of lands for more effective tilling, irrigation and erosion prevention of their lands. At extreme distances their laser level measures accurately for reshaping their lands and field divisions for high-grade work.

Landscapers

Contractors for landscapers make good use of their laser level on hardscapes like paver patios, retaining walls, garden beds and outdoor kitchens. They use their laser level to correctly terrace sloped lawn spaces to build walls with precise slope or to level paver patios perfectly. They have effective success in numerous other landscaper jobs with their laser level or their level model that has to be set level by level by their own measurement.

How to Choose a Rotary Laser Level?

When selecting a rotary laser level, it's important to consider the intended application – whether for indoor or outdoor projects. For indoor projects like laying tile or hanging drywall in small enclosed rooms, a multi-line laser level like the Huepar RL300HVG Laser Level can work well. Its three bright laser lines provide ample coverage and visibility.

For outdoor jobs spanning longer distances or on uneven surfaces, a rotary laser level mounted on a secure tripod offers superior stability and range. The Huepar 603CG, with its impressive 2000ft diameter coverage, excels at tasks like establishing slopes for drainage, leveling foundations, or landscaping over large areas.

Pay attention to the rotation speed (RPM) – higher RPMs provide faster laser detection over greater distances. For example, the Huepar RL300HVG Laser Level's 600 RPM is ideal for outdoor construction, while the 622CR's 200 RPM suits indoor remodeling jobs.

Self-leveling models automatically level themselves when set up within 4-5 degrees of level. This hands-free leveling works well for uneven outdoor terrain. For very stable indoor floors, a manual leveling model can suffice.

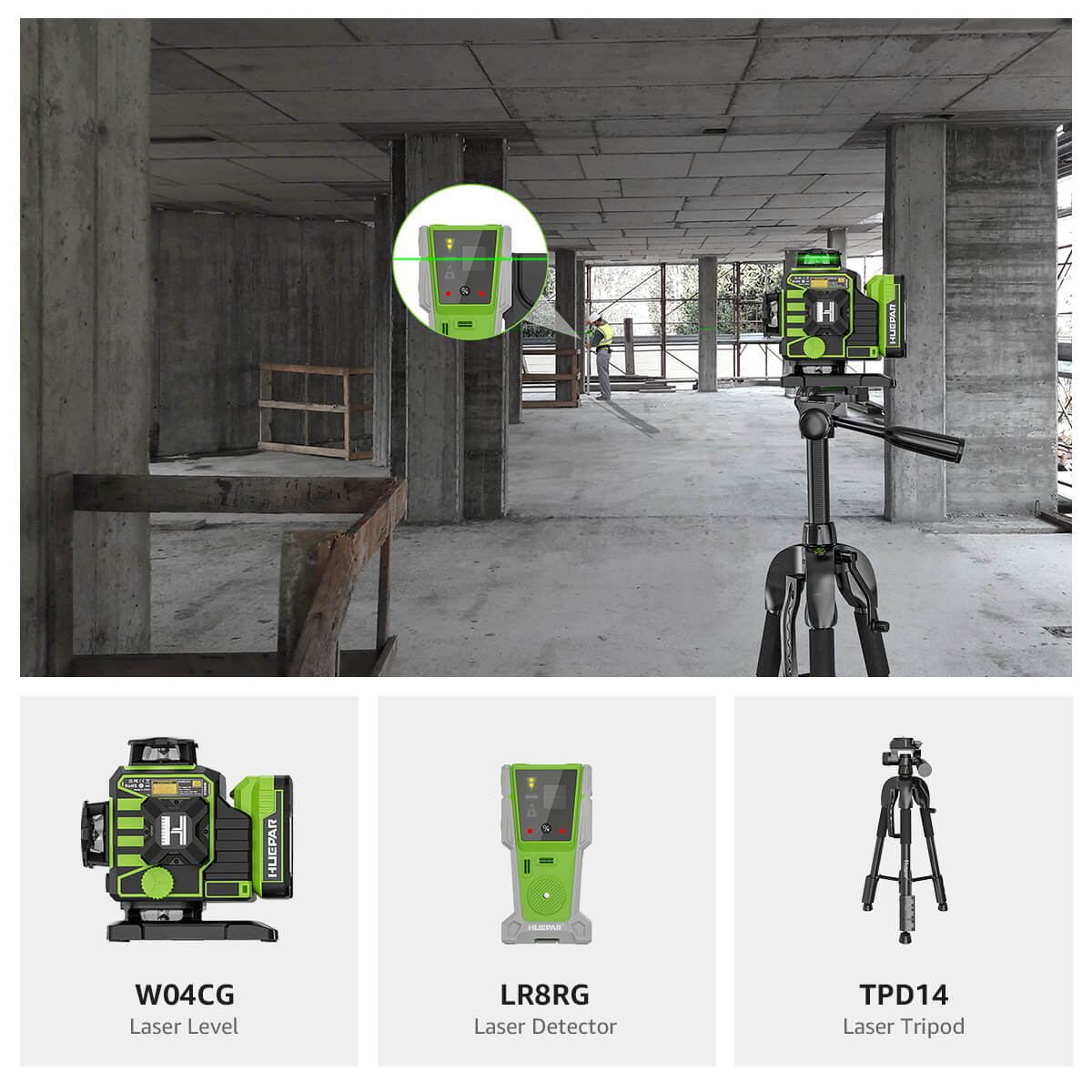

Using a quality tripod like Huepar's aluminum tripods ensures maximum stability and accuracy. For quick jobs, a bucket or sawhorse can work in a pinch indoors.

Rotary Laser Level Setup, Operation, Calibration & Safety

Proper setup and operation of a rotary laser level is crucial for accurate and efficient indoor and outdoor projects. Here are some key considerations:

Setup:

- Choose a stable, level surface to mount the laser level on a tripod or other secure base

- Position the laser level as close to the center of your work area as possible for maximum range

- Make sure the laser level is properly calibrated before use (see calibration section below)

Operation:

- Power on the laser level and allow it to self-level if using an automatic model

- Select the desired rotation speed - higher RPM for longer distances, lower RPM for shorter ranges

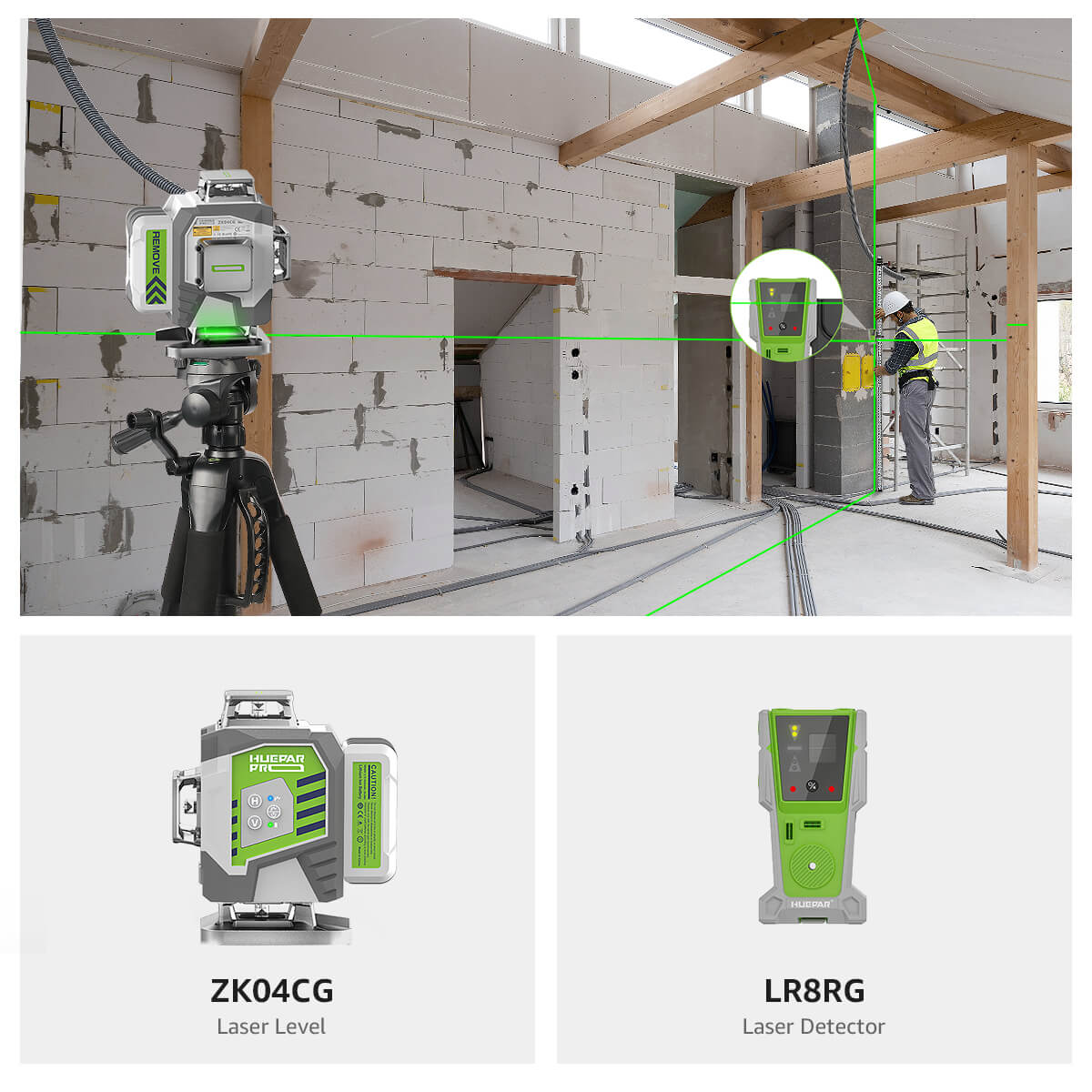

- Use the laser receiver or detector to pick up the laser beam, especially in bright outdoor conditions

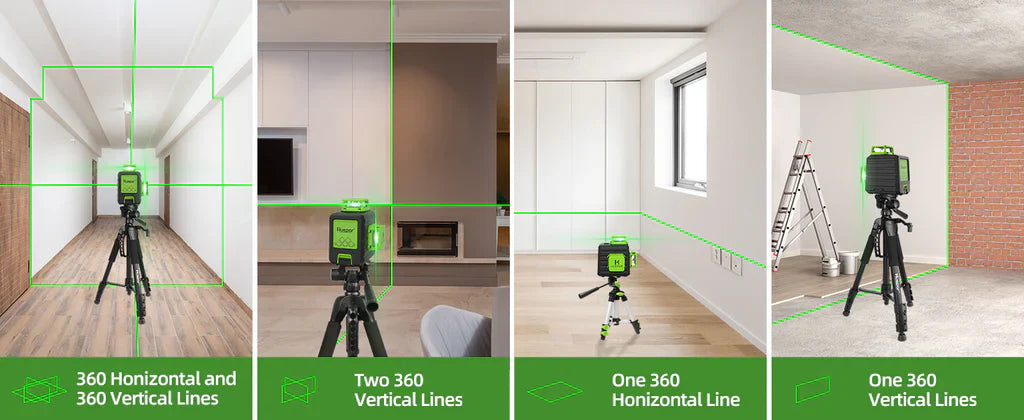

- For indoor jobs, use the laser level to project multiple horizontal, vertical, or cross-line laser beams

Calibration:

- Rotary laser levels can go out of calibration due to drops, vibrations, or temperature changes

- Follow the manufacturer's instructions to check and adjust calibration regularly

- Use a precise calibration procedure over known distances and against fixed references

Safety:

- Never look directly into the laser beam as it can damage your eyes

- Use the laser receiver or detector to locate the beam instead of exposing your eyes

- Set up barricades or post laser warning signs in public areas during outdoor use

- Remove batteries when not in use to prevent accidental laser exposure

By properly setting up, operating, calibrating, and observing safety protocols, you can ensure accurate and safe use of your rotary laser level for a wide range of construction applications.