How to Use a Construction Laser (Indoors & Outdoors)

Indoor Applications for Construction Laser Levels

Construction laser levels are excellent tools for a variety of home improvement applications throughout the house. Whether you need to hang drapes or drapery, cabinets or shelves, picture frames or paintings, level floors for tile or hardwood installation, or install room additions or remodels, a laser level can give you accurate measurement and alignment.

For drapes or drapery hanging, a laser level can project a straight line across a wall, allowing you to mark exactly where to hang curtain rod brackets. This results in a level, even hang for your window treatment. In cabinet or shelf installation, a laser level can be used to mark studs and keep the units perfectly leveled during installation.

Aligning picture frames or paintings is also a job easily done using a laser level. Instead of eyeballing it or using a plain old level, you can project a line of laser across a wall and use it to guide you in hanging pieces in a straight, even line. This is helpful when working with a collection of frames or in creating a gallery wall.

If you're preparing to install new tile or hardwood flooring, a laser level can help you spot any slope or hump in a subfloor that needs to be leveled before new flooring is installed over it. This can prevent such problems as lippage or a warped completed floor.

For larger construction work such as a remodel or a room addition, a laser level is a necessity when installing walls, doorways, and other framing elements. By projecting a line of level, you can get new construction plumb and square, a condition that a sturdy and aesthetically pleasing end product demands.

Outdoor Uses for Construction Laser Levels

Laser construction levels are a necessity when outdoors, providing accurate and precise measurement in applications of levelling and grading. One of their most utilized applications is to level terrain for a walkway, a patio, or a deck. By placing a laser level and using a receiver, you can get a perfectly even terrain, eliminating potential hazards of a rough or unlevel terrain.

Landscaping applications such as garden installation or installing a water feature also require a laser level to their application. The tools allow you to grade terrain to a precision measurement, providing drainage and aesthetic design to specifications. From garden bed construction to designing a serene pond, a laser level can assist you in getting to that desired slope and contours.

Fencing installation is also a place a laser level is a stand-out performer. By installing a laser level in a desired position, you can mark fence post spots easily, ensuring fence posts perfectly even and in line. This not just beautifies the fence but also makes it structurally solid and a more resilient installation.

Driveways and parking areas must be precisely leveled to prevent pooling of water and ensuring drainage is in place. With a laser level, you can set a desired position of elevation and grade accordingly, resulting in a smooth, usable vehicle space.

Finally, laser levels are crucial when marking up excavations for ponds or pools. By providing accurate depth and slope readings, you can be certain that the excavation is correctly set up for the intended water feature, preventing potential structural problems or leakage of water.

Overall, construction laser levels give homeowners and professionals a useful instrument for a multitude of outdoor applications, providing precision, accuracy, and efficiency in the process.

Key Factors When Choosing a Laser Level

Several key aspects need to be taken into account when picking a construction laser level to ensure you obtain a suitable instrument for the job. Durability is paramount, particularly for job-site use where the instrument is likely to be exposed to drops, moisture, dust, and extreme temperatures. Choose sturdy housings and protection that can withstand harsh environments.

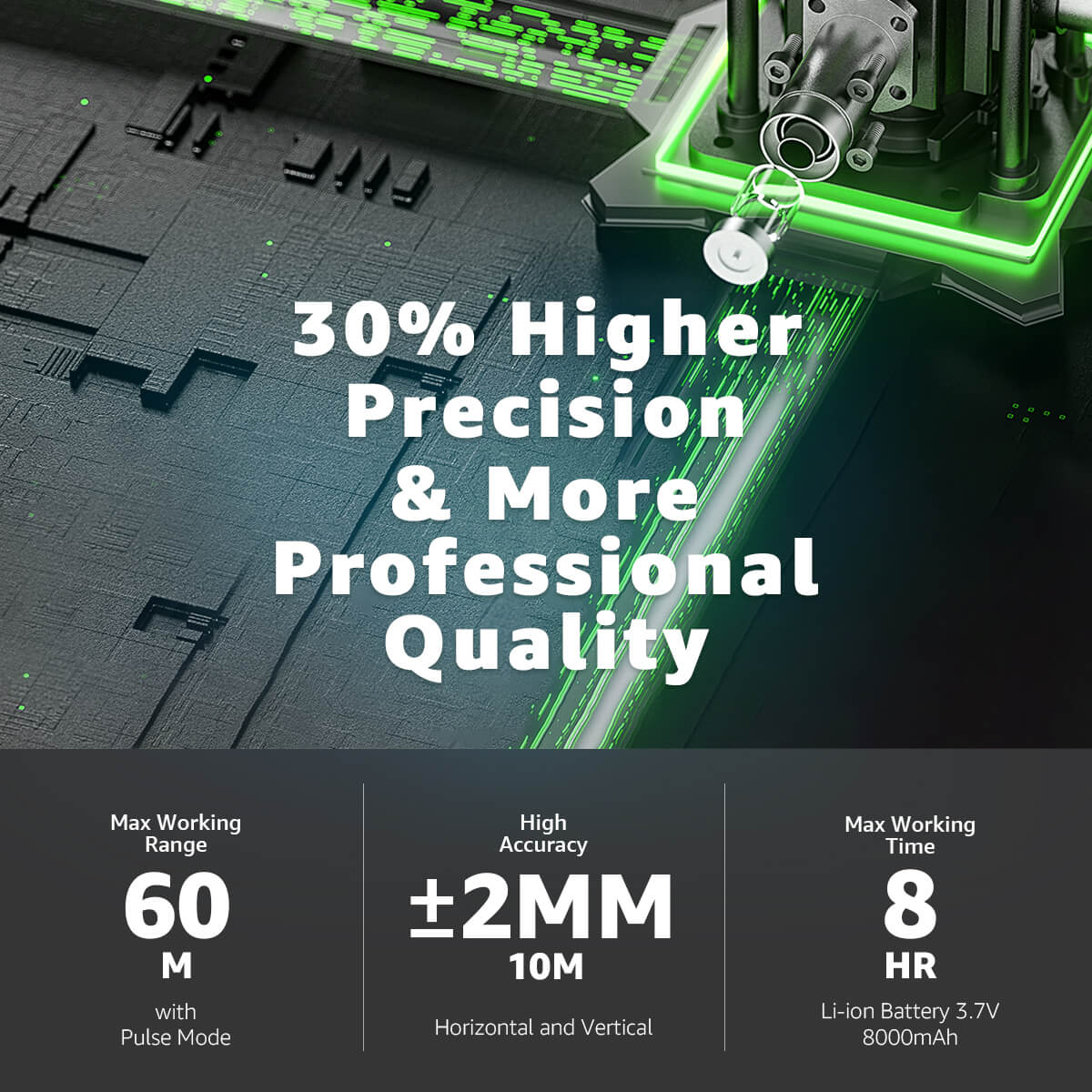

Precision and accuracy are paramount for any laser instrument. Top-tier models deliver higher precision to 1/16 of an inch or better over long distances. The precision means that your layout line, elevations, and surfaces are precisely level and in line.

The color of the beam is also a concern to consider. Red beams are more visible in interior use and in low light, whereas green beams are more visible outdoors and over a farther range. Some models provide red or green beams for use in a wide range of situations.

The working range and class of the laser determine the range that the beam can cast to, as well as in what circumstances it is visible. Greater range rotary models cast beams up to 2,000 feet or more for large-scale outdoor applications.

Battery duration and power options are also a concern. Long-lasting rechargeable batteries provide more time in use, whereas alkaline batteries provide easy to obtain replacements. Some models take AC power to use continually in a home or interior application.

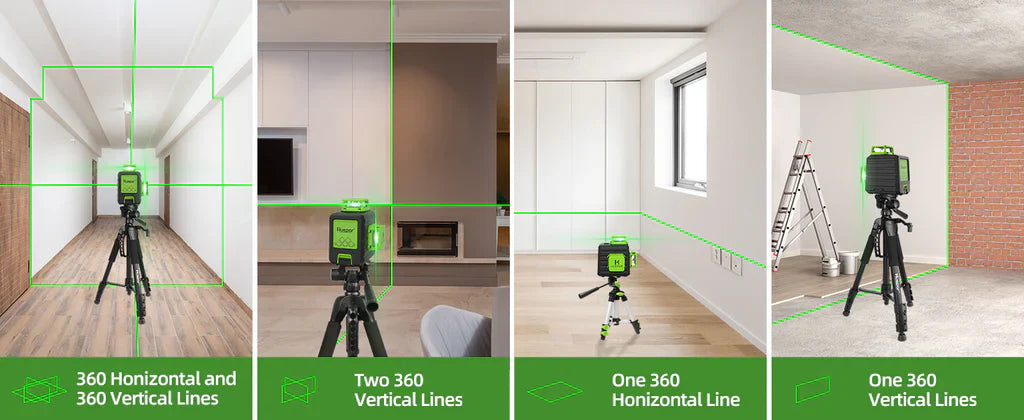

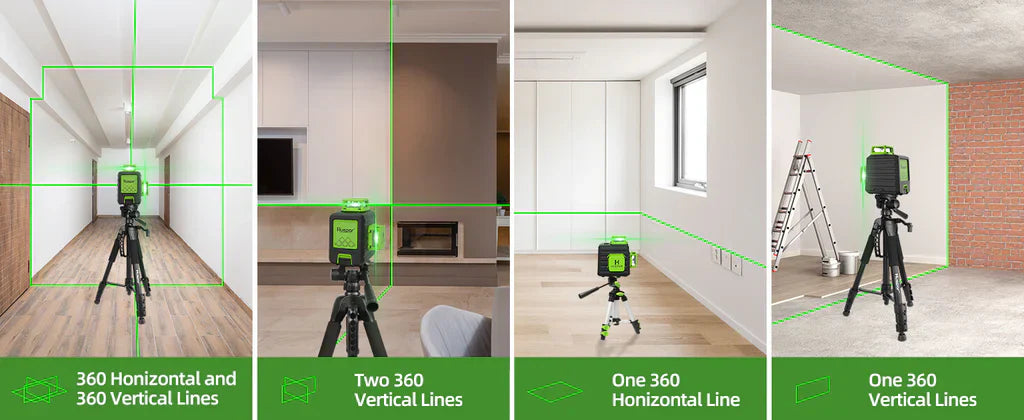

Finally, consider whether you need a wide beam that turns or a point-to-point line-up that is fixed. Rotary levels project a constant 360° beam of laser at all times, while cross-line lasers project horizontal, vertical, and even square patterns when in a fixed position.

Top Rotary Laser Level Recommendations

Huepar 902CG Self-Leveling Cross-Line Laser

The Huepar 902CG is a self-leveling cross-line laser used in interior applications such as picture hanging, cabinet installation, and tile lining. The green beam is easily visible even in bright environments. The compact, lightweight design of this laser level is easy to handle and transport. With a range of up to 130 feet, it is great for small to medium work. The 902CG also includes a pulse mode for use with a sensor, making it even more convenient.

Huepar RL300HVG Green Rotary Laser Level

The Huepar RL300HVG is a green rotary laser level used in interior or exterior work. The green beam is four times brighter compared to red beams, making it more visible in bright situations. With a range of up to a 2,624 feet in diameter, it is great for medium to large work. The build is heavy-duty and rugged, having an IP66 rating for protection against dust and water. The RL300HVG also includes self-leveling capability and multiple modes of scanning, making it a convenient product for a wide range of construction and leveling applications.

Tips for Using Laser Levels Effectively

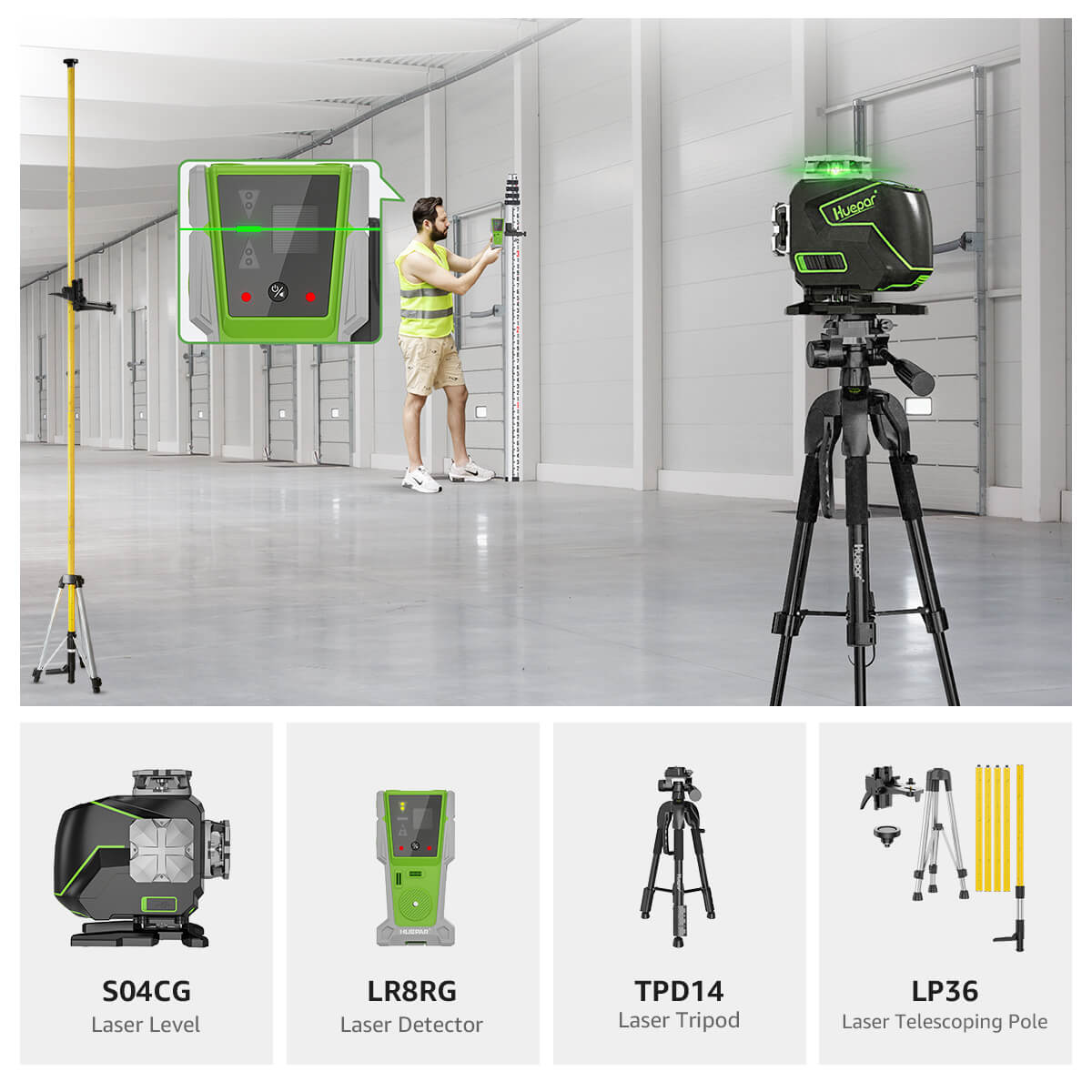

Mount your laser level on a sturdy, level tripod or platform to get accurate readings. Any lean, even a little one, can skew your readings at distances over that. Level and lock in position the tripod legs or laser plate temporarily.

It's a good practice to periodically calibrate your laser, such as after having been shaken up or dropped around. Most high-quality lasers give you a basic process you can use to keep it accurate.

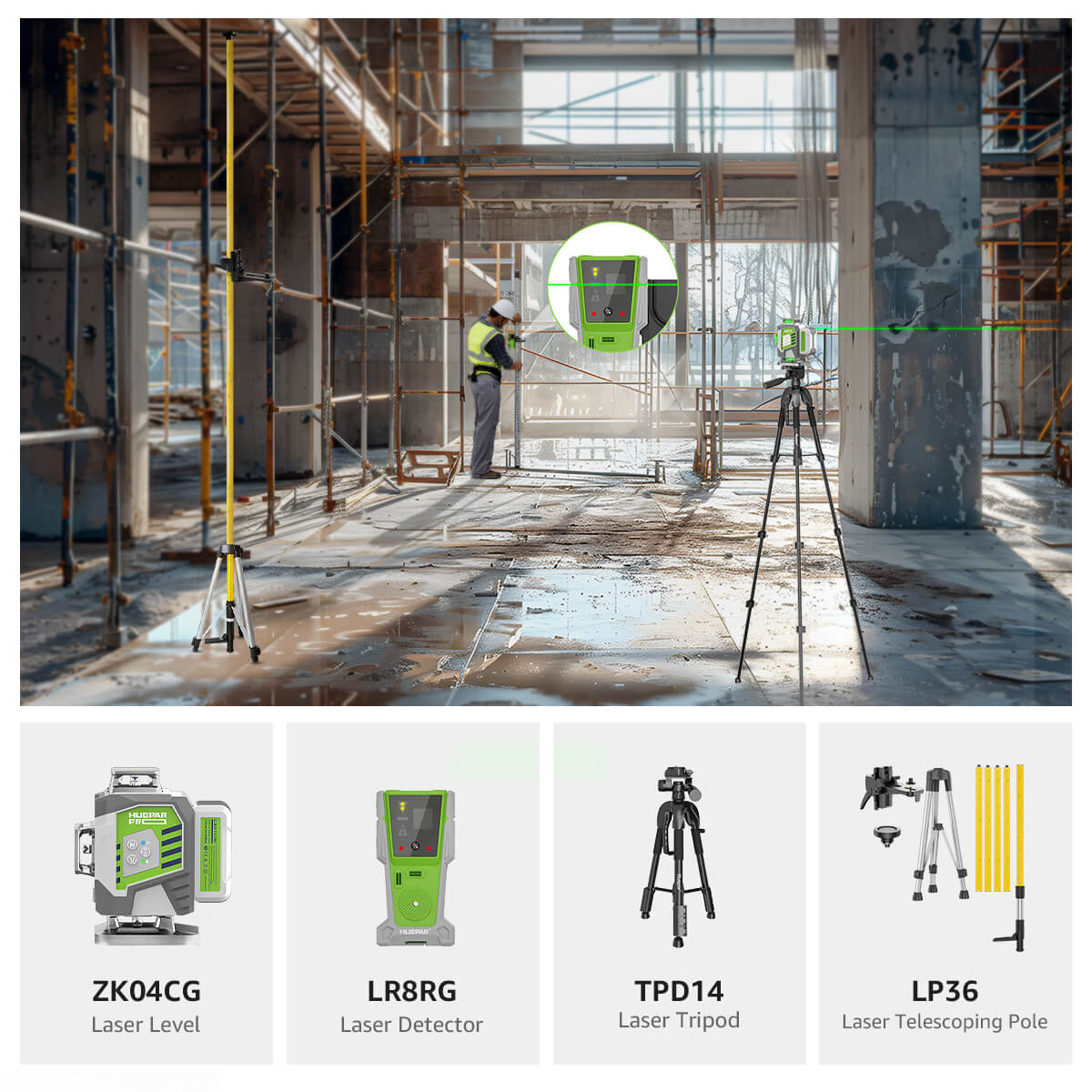

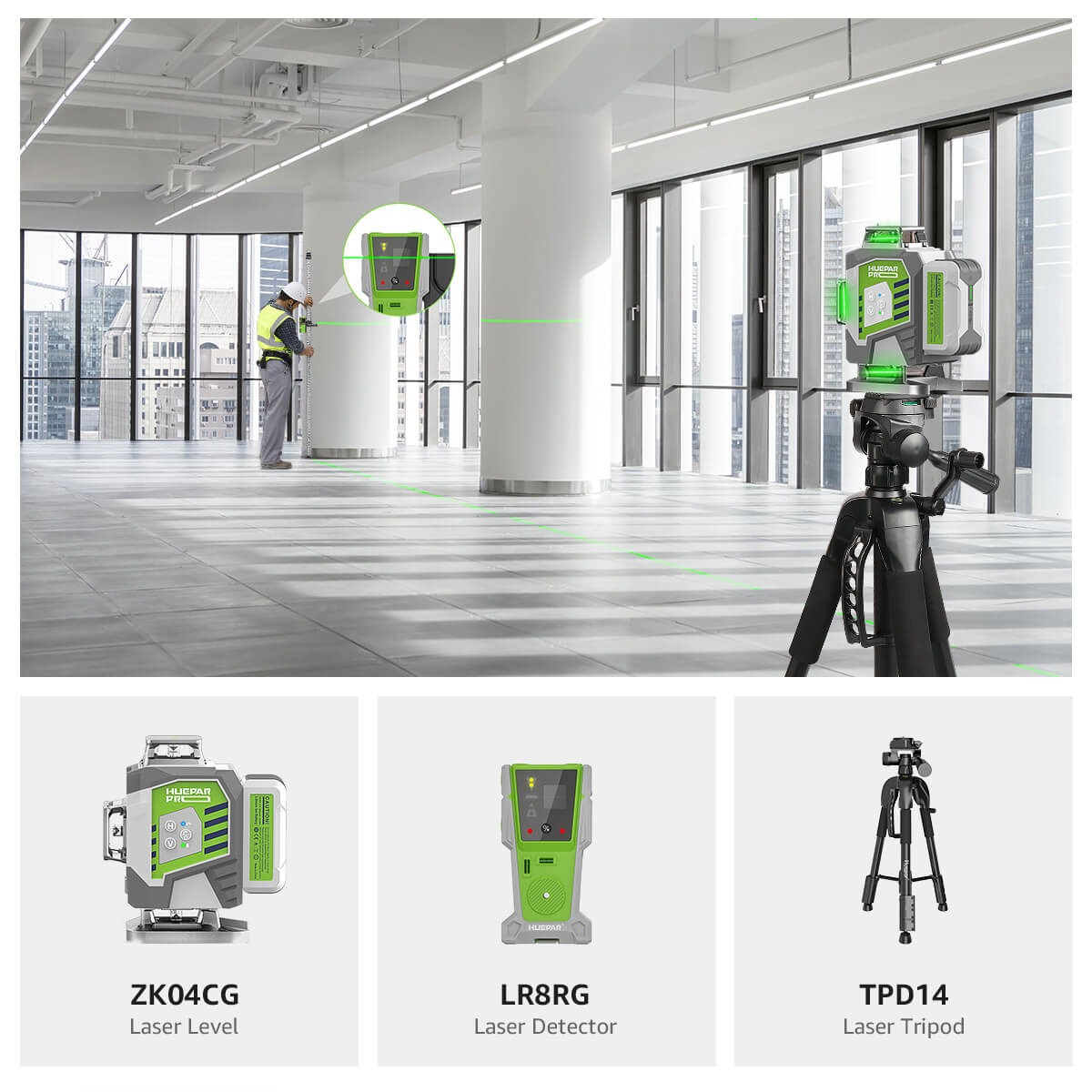

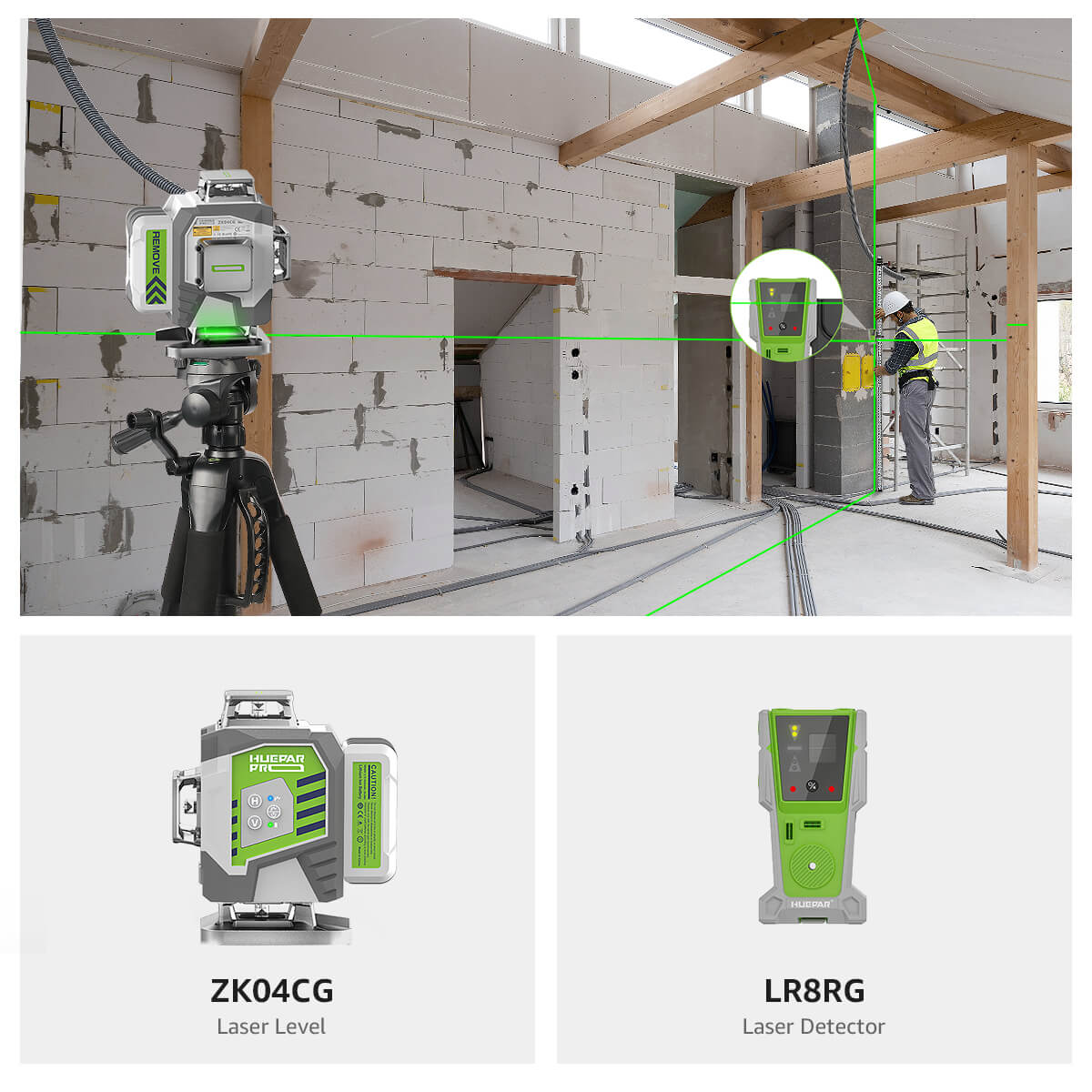

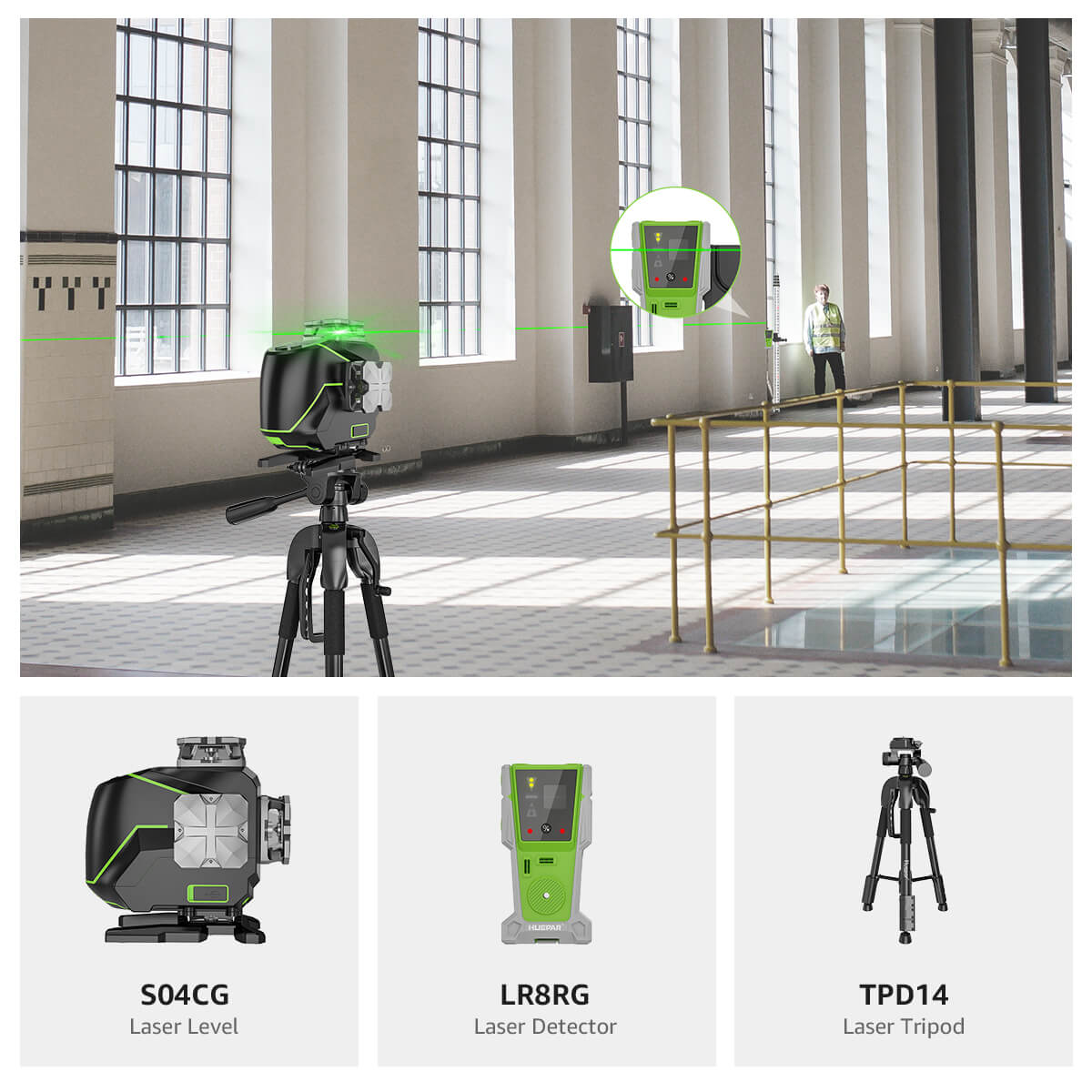

For use in large interior spaces or outdoors, laser detectors can greatly boost usable range by making the beam visible over distances. Buy a detector compatible to the same wavelength of your laser.

Laser levels contain fragile optics, so it's a good practice to keep them away from dirt, debris, and moisture when not in use. Always store them in their carrying cases and transport the optics in a cover.

While highly useful in layout work and leveling, laser levels work best when used in conjunction with other job-site tools such as string lines and measurement tapes. Use the laser to place your reference line, then use conventional methods to measure and mark it.