Unlock the Precision of 3D Laser Levels: Your Ultimate Guide to Enhanced Leveling

Understanding Laser Levels

What are Laser Levels?

Laser levels are tools that emit a straight beam of light. This light is used to create a level line across a surface. The line helps ensure accuracy when working on various projects. They are vital in construction, carpentry, and DIY tasks. By projecting horizontal and vertical lines, they guide alignment and leveling. Laser levels come in different types: dot, line, and rotary lasers. With advancements, we now have 3d laser levels. They offer more precise control, allowing for full-room leveling.

Different Types of Laser Levels

Laser levels come in various forms, each suited to different tasks. Here is a rundown of the most common types:

- Dot Lasers: Project simple dots on surfaces. Ideal for basic leveling.

- Line Lasers: Emit continuous horizontal or vertical lines. Great for aligning objects.

- Rotary Lasers: Cast a 360-degree level line around a room. They work well for large-scale work.

- Cross Line Lasers: Produce intersecting horizontal and vertical lines. They offer more reference points.

- 3D Laser Levels: Display lines on all three planes. Perfect for complex layouts and precision.

- 4D Laser Levels: Similar to 3D types but with added features like Bluetooth connectivity.

Each type has its own perks and is key to making a well-informed purchase.

The Evolution of Laser Levels: From Traditional to 3D Tech

Laser levels have come a long way since their inception. In the early days, simple spirit levels with a laser pointer attachment were common. But as technology advanced, so did these leveling tools. We now have 2D laser levels that project lines on a single plane, and cross line lasers which display intersecting horizontal and vertical lines. The game-changer, however, is the 3D laser level. This high-tech tool casts a three-dimensional grid of light, offering superior accuracy. It creates points and lines on all surrounding surfaces. As we embraced digital tech, 4D laser levels entered the market. These advanced levels connect to apps for more control and precision. Their evolution shows a clear trend towards more accurate, user-friendly tools for professionals and DIY enthusiasts alike.

3D Laser Levels Explained

What Makes 3D Laser Levels Stand Out?

3d laser levels revolutionize precision in projects. Unlike traditional or 2D levels, they project three planes. This means they offer 360-degree coverage without moving the tool. With a 3D laser level, users can get horizontal and vertical lines at the same time. This dual-projection makes aligning and leveling across multiple walls a breeze. They're also equipped with advanced self-leveling features. This ensures accuracy even on uneven surfaces. For professionals and DIY enthusiasts, this translates to time saved and improved accuracy. 3D laser levels are indeed the next step in leveling technology, providing unmatched utility in a variety of environments.

How Do 3D Laser Levels Work?

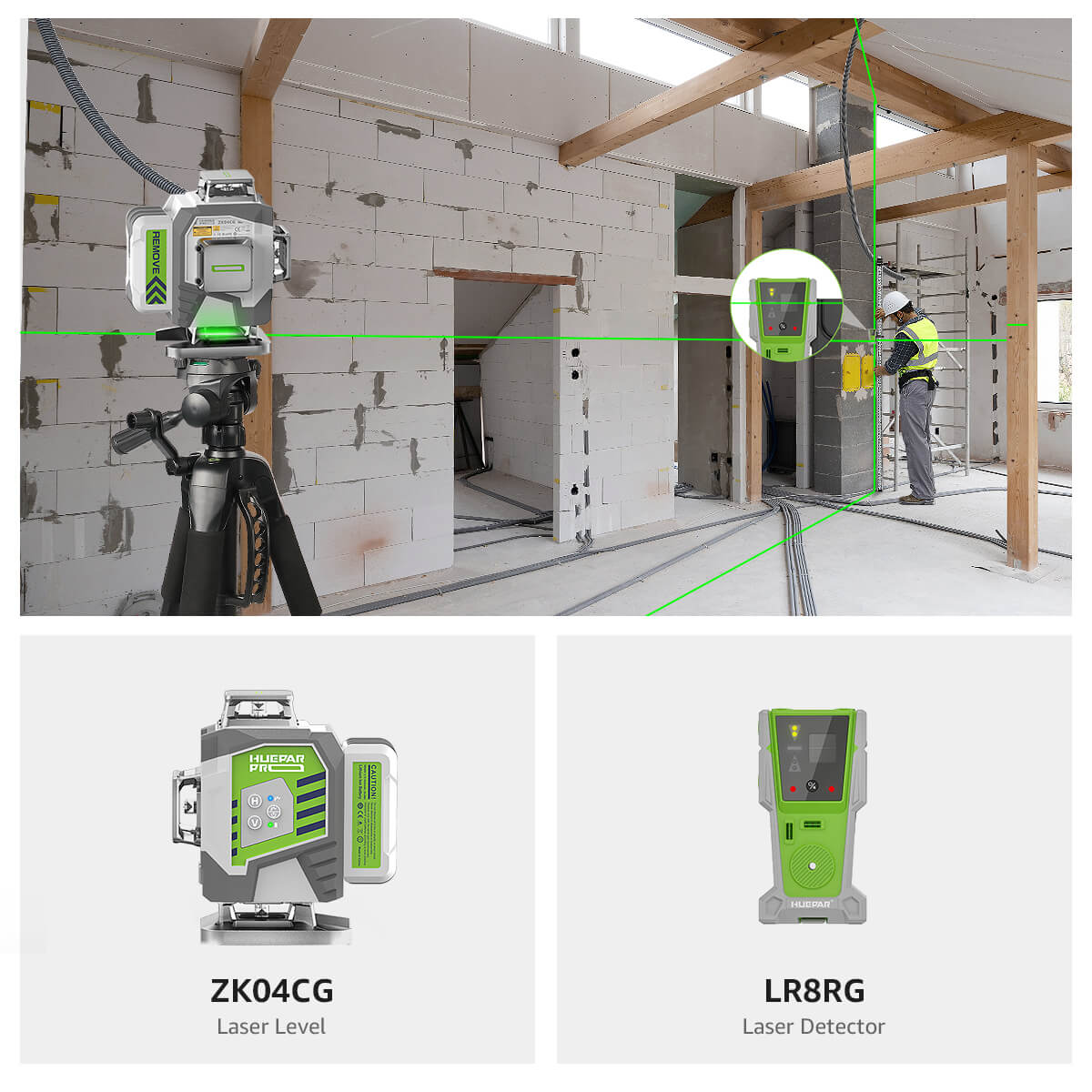

3d laser levels are advanced tools that create precise reference points and lines. They project a grid of laser lines onto surfaces at a 90-degree angle to each other. This makes it easier to align and level items along three planes: horizontal, vertical, and depth. Inside a 3D laser level, a diode emits a laser beam. This beam is then split into multiple lines through prisms or mirrors. High-tech sensors and self-leveling motors ensure the laser lines are accurate. Some models come with receivers for outdoor use. With their ability to guide installations and alignments, 3D laser levels are a game-changer in precision tasks.

Benefits of Using 3D Laser Levels in Construction and DIY Projects

The integration of 3d laser levels into construction and DIY projects has revolutionized precision and efficiency. Accurate Measurements: Unlike traditional levels, 3D laser levels provide accurate, 360-degree horizontal and vertical lines. This reduces errors in alignment and leveling. Time-Saving: They dramatically reduce the time needed to set up and check levels, speeding up project timelines. Versatility: With the ability to project lines along three planes, 3D laser levels are versatile tools suitable for a variety of tasks, from installing cabinets to laying tiles. Ease of Use: They are designed for easy operation, making them accessible to professionals and hobbyists alike. Increased Safety: Remote operation allows users to avoid precarious setups, enhancing workplace safety. Overall, the benefits of 3D laser levels make them indispensable tools for accurate and efficient project outcomes.

Choosing and Using 3D Laser Levels

Factors to Consider When Buying a 3D Laser Level

When shopping for a 3D laser level, there are several factors to evaluate:

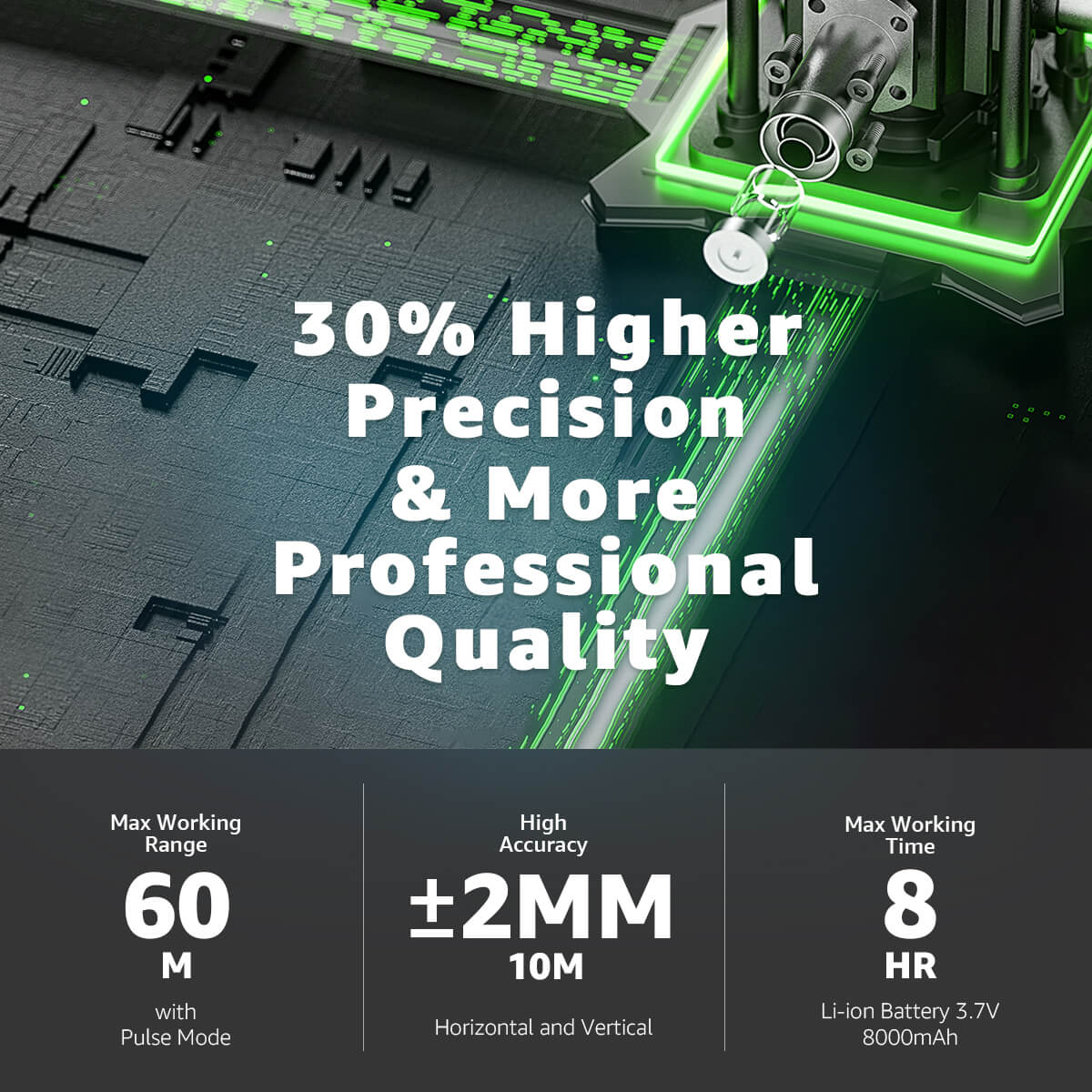

- Accuracy and Range: Look for units with a high degree of accuracy and sufficient range for your needs.

- Self-Leveling Capability: Choose a model that automatically levels for ease of use.

- Battery Life: Ensure the device offers a long battery life or has convenient power options.

- Durability: Opt for robust construction, especially if you'll use it in rough environments.

- Additional Features: Consider extra functions like Bluetooth connectivity, which can enhance versatility.

- Price: Set a budget, but remember that quality is key for professional-level projects.

- Warranty and Support: Check the warranty period and if the brand provides reliable customer support.

Prioritize these aspects to find a 3D laser level that matches your project requirements and budget.

Tips for Using 3D Laser Levels Accurately

To get the best results from your 3D laser level, follow these simple tips:

- Read the Manual: Start with the device manual. It has key info you need.

- Calibrate Regularly: Ensure accuracy by calibrating your tool often.

- Stable Setup: Place the laser level on a stable surface to prevent movement.

- Clear Line of Sight: Remove any obstacles that could block the laser's path.

- Check Battery: A low battery can affect the laser's performance. Change it when needed.

- Avoid Direct Sunlight: Direct sun can make laser lines hard to see. Use it in shade or dim light.

- Use Target Plates: These help to see the laser better, especially over long distances.

- Double-Check Measurements: Always double-check your work for the best precision.

Maintenance and Safety for Laser Levels

Proper maintenance and safety measures are crucial for the longevity and safe operation of 3d laser levels. Here are key points to consider:

- Always store your 3D laser level in a protective case to avoid damage from dust, moisture, or impact.

- Regularly clean the laser windows with a soft cloth to ensure clear and accurate beams. Avoid using harsh chemicals that can damage the optics.

- Check the calibration frequently, especially after the device has been dropped or jolted, to maintain precision.

- Replace batteries or recharge the device as recommended by the manufacturer to prevent power failures during use.

- Follow the manufacturer’s guidelines for operating temperatures to avoid compromising the laser level’s performance.

- Never point the laser beam directly at anyone's eyes, as the intense light can cause serious eye injury.

- Use caution when operating the laser level on a tripod or elevated surface to prevent tipping and falls.

It's essential to refer to your specific model's user manual for more detailed maintenance and safety instructions.