Unlocking Precision: A Comprehensive Guide to 3D Laser Levels

What are Laser Levels and How Do They Work?

The Basics of Laser Level Technology

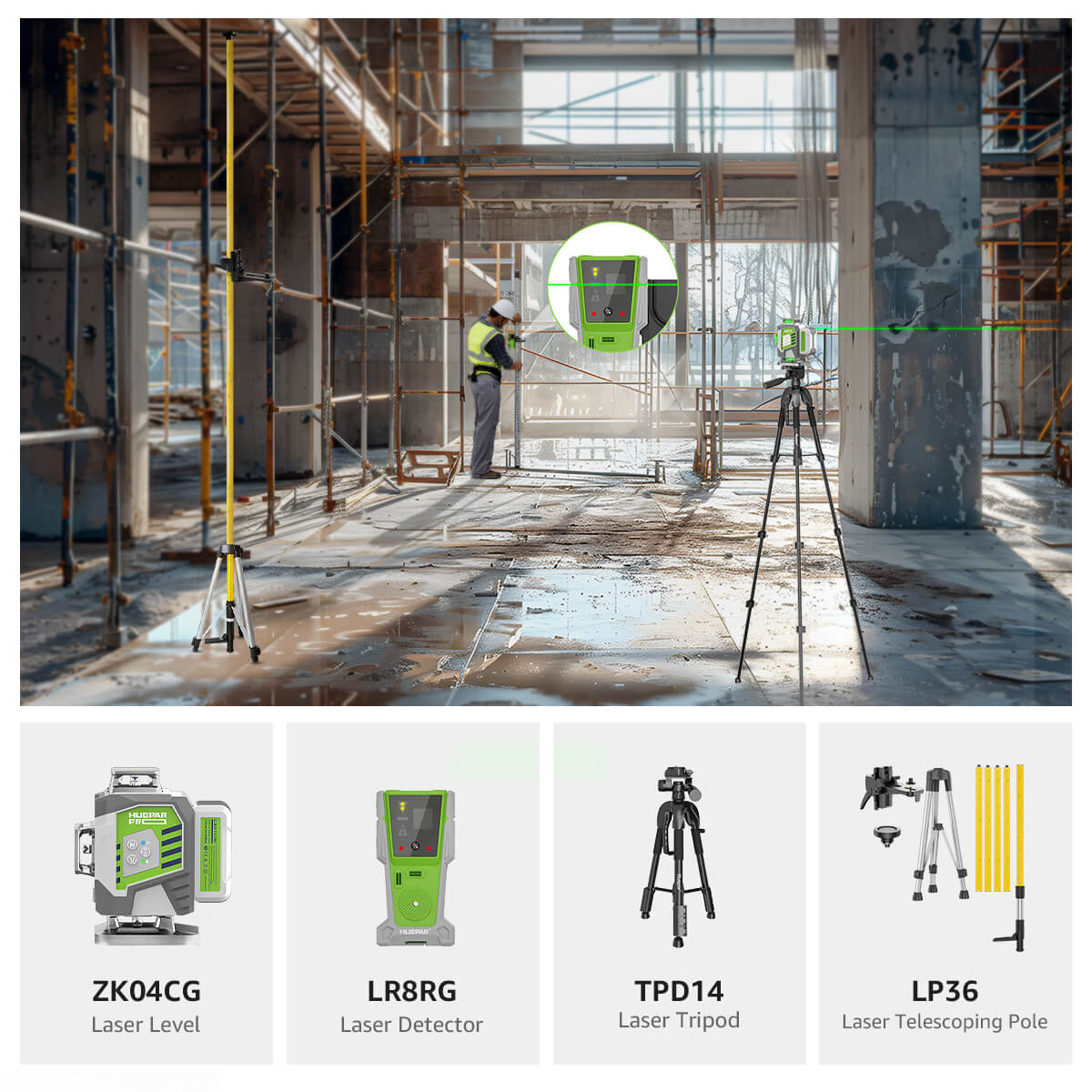

Laser levels are high-precision tools that emit a straight, level laser beam. This beam acts as a visual guide for aligning objects or marking reference points. They work by projecting a laser dot or line — visible or invisible — across surfaces. The setup typically includes a laser emitter mounted on a tripod or base, which can be adjusted to the desired height and angle. Users position the level, turn it on, and follow the laser line to maintain a consistent elevation, ensuring accuracy in tasks like hanging pictures or laying tile.

3D vs. Traditional Laser Levels: What's the Difference

3d laser levels take traditional leveling up a notch. Unlike typical laser levels that emit a single line, 3D variants project three planes of light, creating a 'box' of lines. This 'box' allows you to work on all axes: horizontal and vertical, making it perfect for tasks needing complex alignment and space mapping. In essence, a 3D laser level can give you a complete room layout with just one setup. On the other hand, traditional laser levels might need repositioning to cover multiple axes. This difference is key when choosing the right laser level for intricate projects, as 3D laser levels offer comprehensive spacial readings which are critical for precision work in construction and various design fields.

The Advantages of Using 3D Laser Levels

Enhanced Accuracy in Construction and DIY Projects

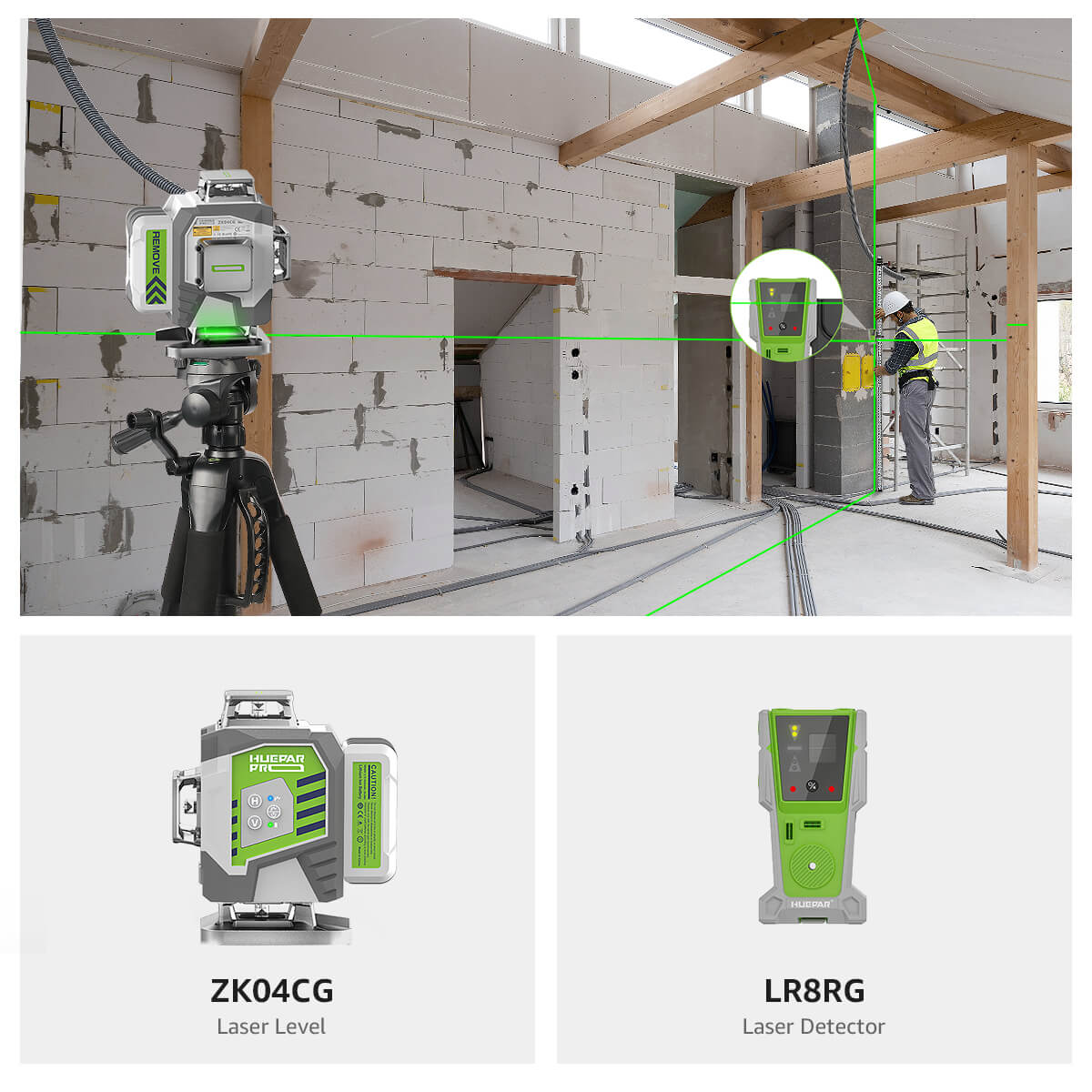

3d laser levels offer unmatched precision which is crucial in construction and DIY projects. The three-dimensional planes allow users to align and position components with greater precision than traditional levels. This accuracy can significantly reduce the risk of costly errors. Even complex installations become simpler, as 3D levels provide clear guidelines across multiple planes, facilitating a perfect alignment. For serious DIY enthusiasts or professionals, the upgrade to a 3D laser level can be a game-changer. It ensures that precision is consistent throughout the project, from start to finish.

Time-Saving Benefits for Professionals

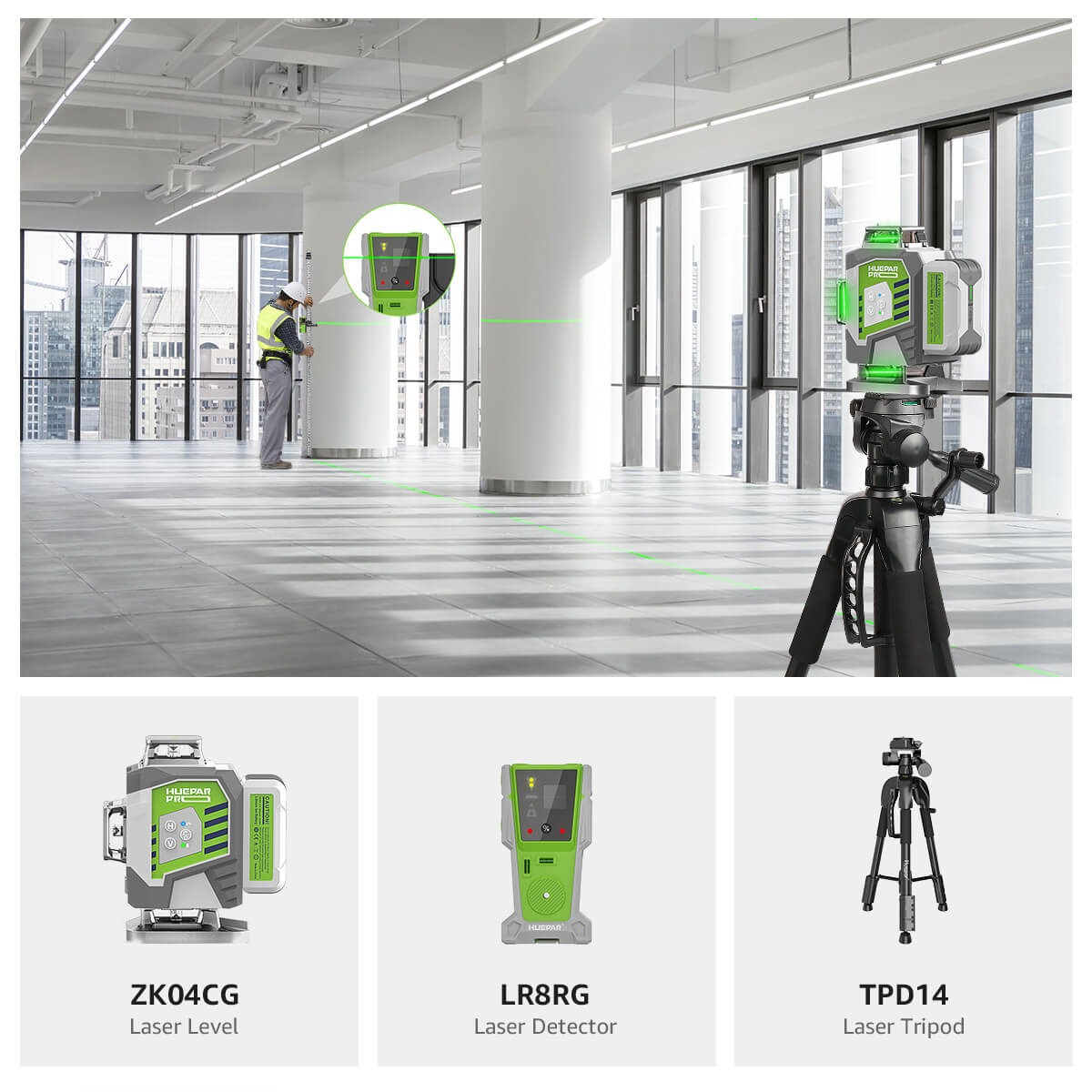

Professionals find that 3d laser levels speed up their work. Unlike traditional levels, these tools project lines in all directions. This means faster set-ups for jobs. Workers can also move less often since the lines cover a full area. Time spent checking levels is cut down too. With clearer, brighter lines, reading levels is faster and errors are fewer. This leads to quicker project completion. Using a 3D laser level is a smart choice for busy pros.

Outdoor vs. Indoor Applications: Maximizing Versatility

3d laser levels shine in both outdoor and indoor settings, offering unmatched versatility. For outdoor projects, they provide clear visibility even in bright conditions. This means laying foundations or aligning structures is quicker and less prone to error. Indoors, 3D lasers make tasks like installing cabinets or tiling floors precise and hassle-free. Their ability to project multiple lines at once allows for complex layouts without constant measuring and marking. This dual-environment adaptability makes 3D laser levels a top tool for varied work settings.

Choosing the Right Laser Level for Your Needs

Cross Line Laser Level: Ideal Scenarios for Usage

The Cross Line Laser Level is a vital tool for many tasks. It projects both horizontal and vertical lines. This makes it perfect for tasks like hanging pictures or installing shelves.

Here are ideal uses for a Cross Line Laser Level:

- Wall tiling or flooring: It helps ensure lines are straight and even.

- Cabinet and countertop alignment: To maintain level surfaces.

- Painting and wallpapering: For flawless borders and patterns.

- Electrical work and plumbing: To keep fixtures aligned.

It's great for both indoor and outdoor projects. It provides clarity and precision where you need it most.

4D Laser Levels Explained

The advancement in laser level technology has given rise to 4D laser levels. Unlike standard 3d laser levels that project in three planes, 4D laser levels cast lines in four directions. This allows users to cover the floor, ceiling, and all four walls with a single setup. Such comprehensive coverage is a boon for tasks requiring the highest precision. The fourth dimension in this context refers to the additional plane of projection, not a time-related feature. These laser levels are often used in complex installations and detailed construction projects where accuracy in all axes is crucial. 4D laser levels typically have a more robust build, higher accuracy level, and a feature set designed for advanced users. However, they can be more expensive and may have a steeper learning curve for those new to using laser levels.

Key Features to Look for in a 3D Laser Level

When picking a 3D laser level, consider these key points:

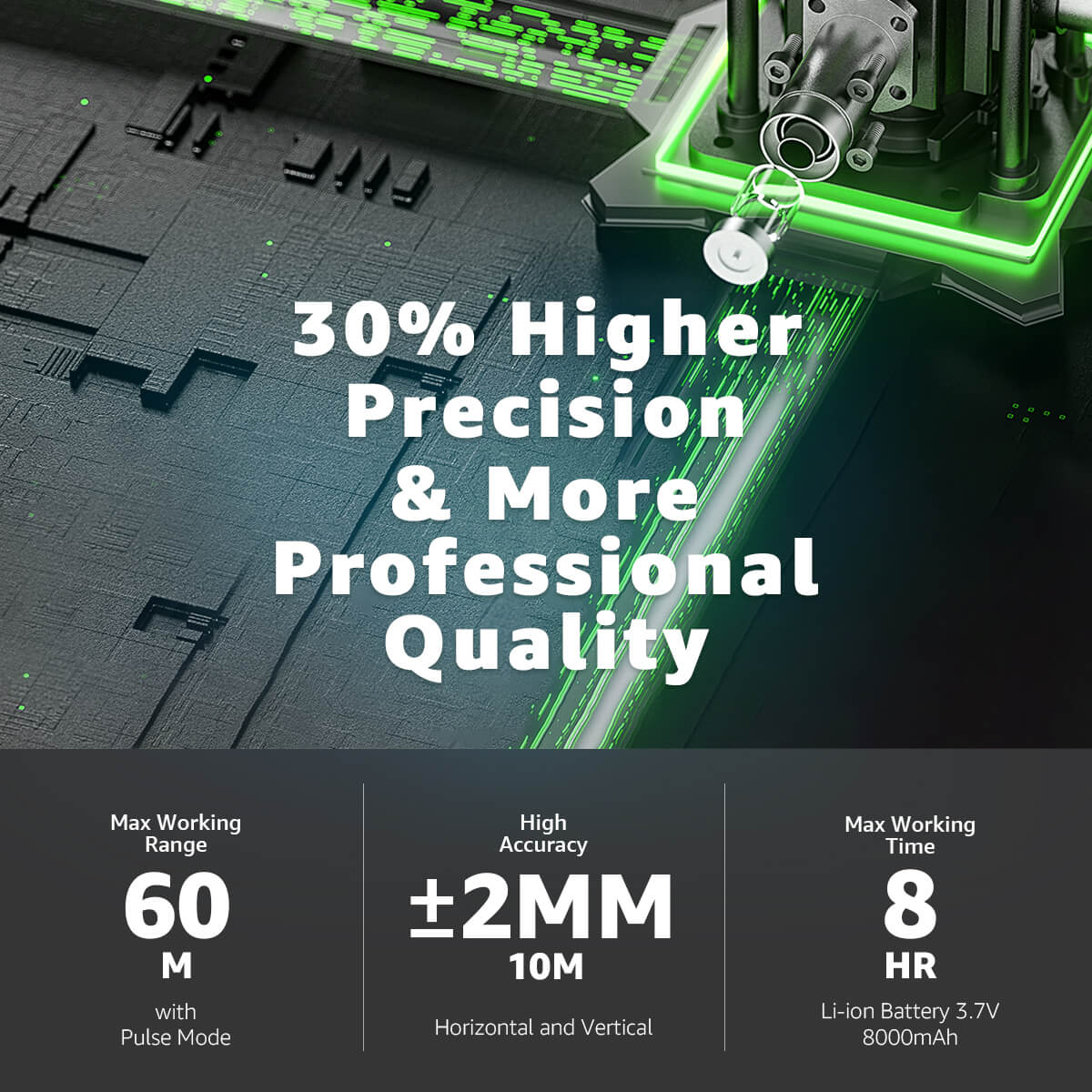

- Accuracy and Range: Look for levels with high precision and ample working distance.

- Self-Leveling Capability: Choose levels that auto-adjust for ease of use.

- Battery Life: Opt for models with long-lasting batteries for uninterrupted work.

- Durability: Ensure the device can withstand tough job sites.

- Ease of Use: Simple controls and clear indicators make the tool user-friendly.

- Mounting Options: Check for versatile mounts for different surfaces.

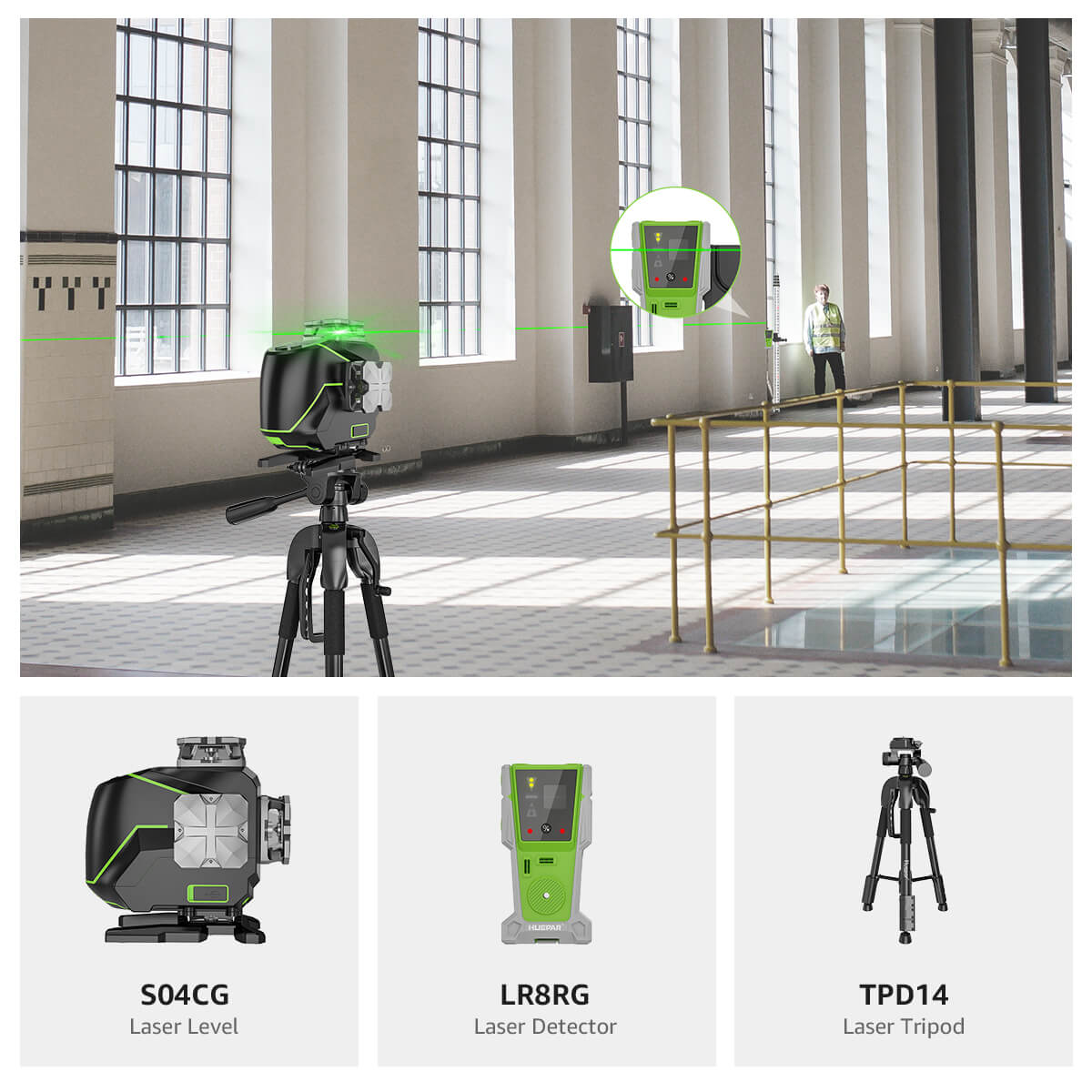

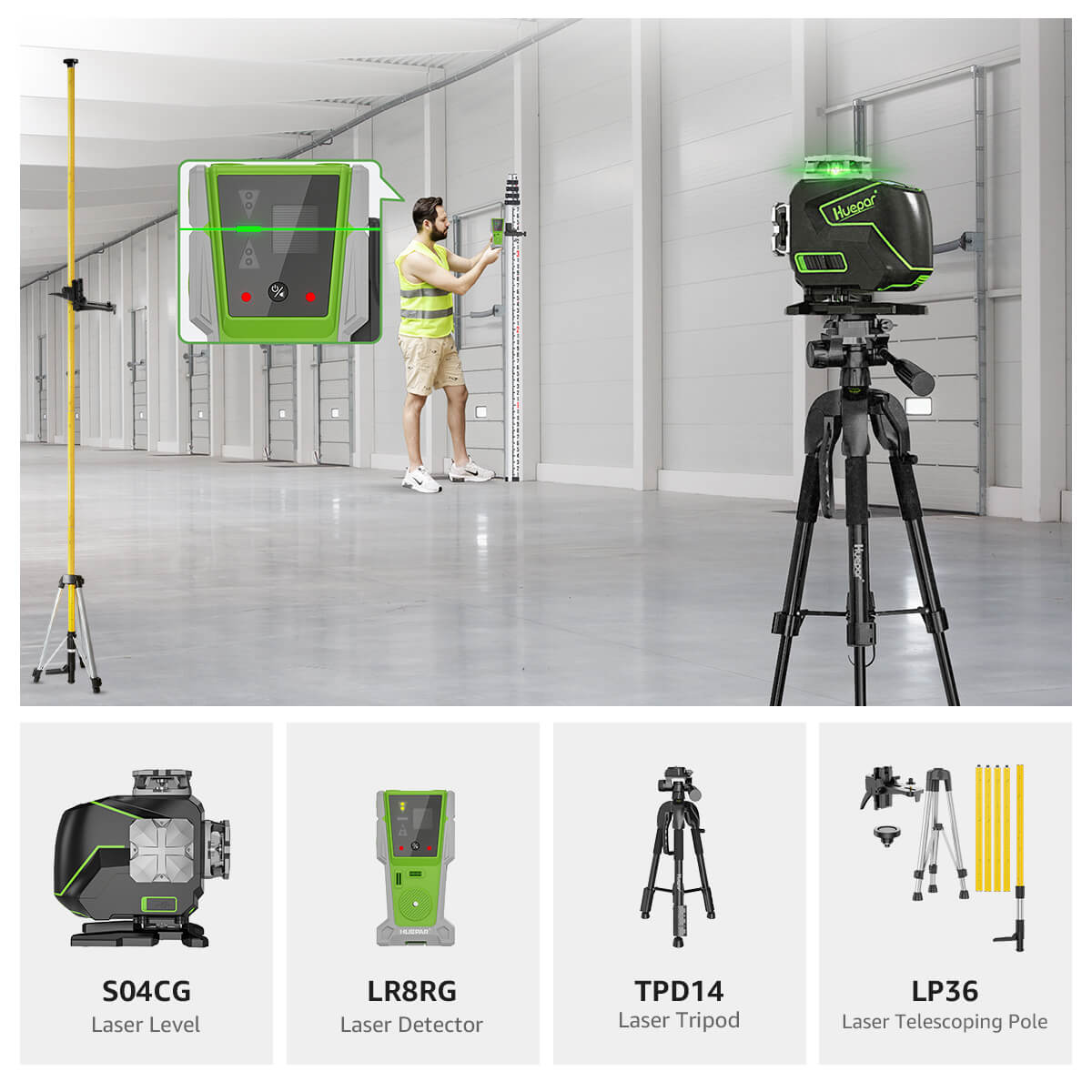

- Accessories Included: Extra items like glasses or target cards are useful.

- Warranty and Support: Longer warranties and good customer support give peace of mind.

Selecting a level with these features ensures reliable results for your tasks.