How to Use a Laser Level for Floors?

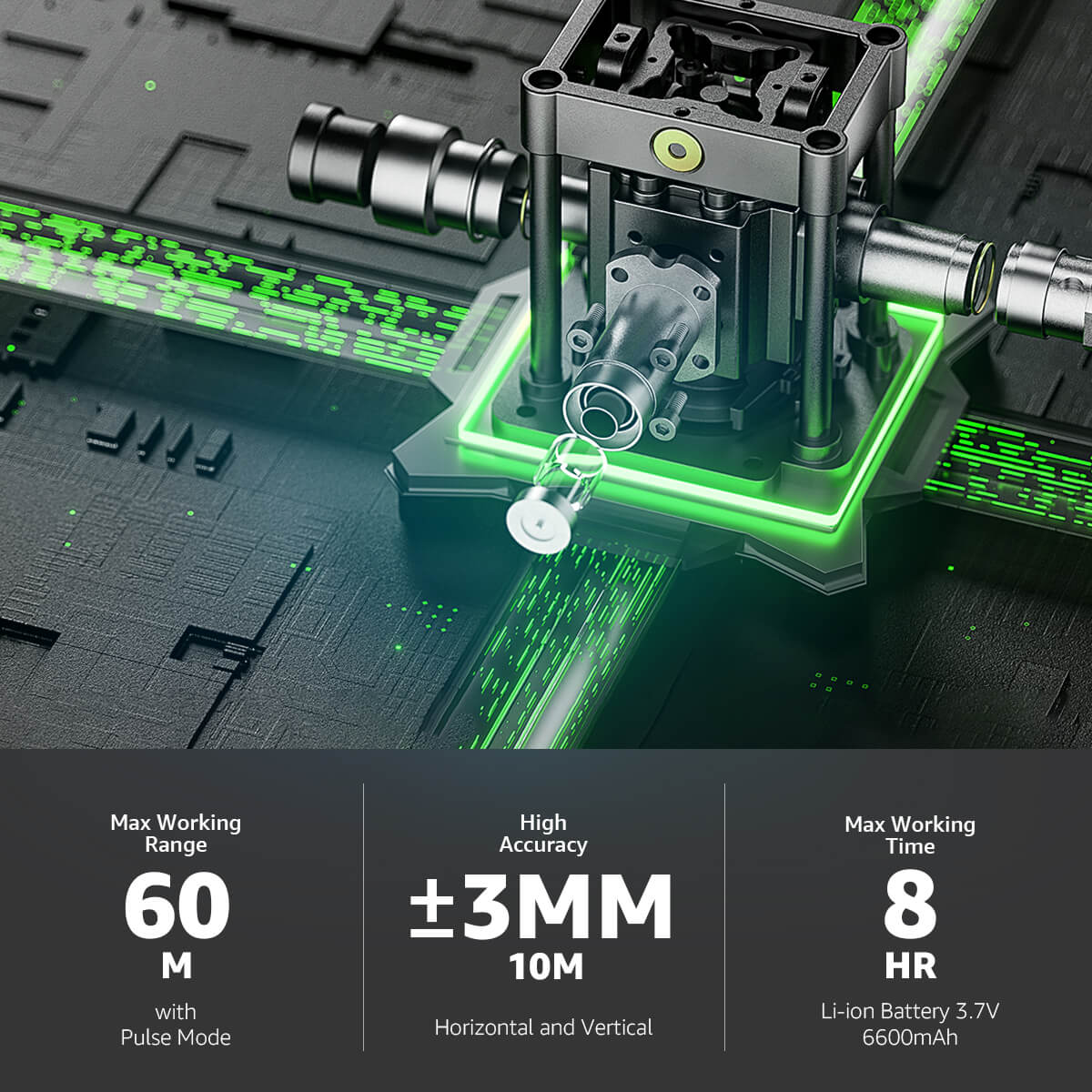

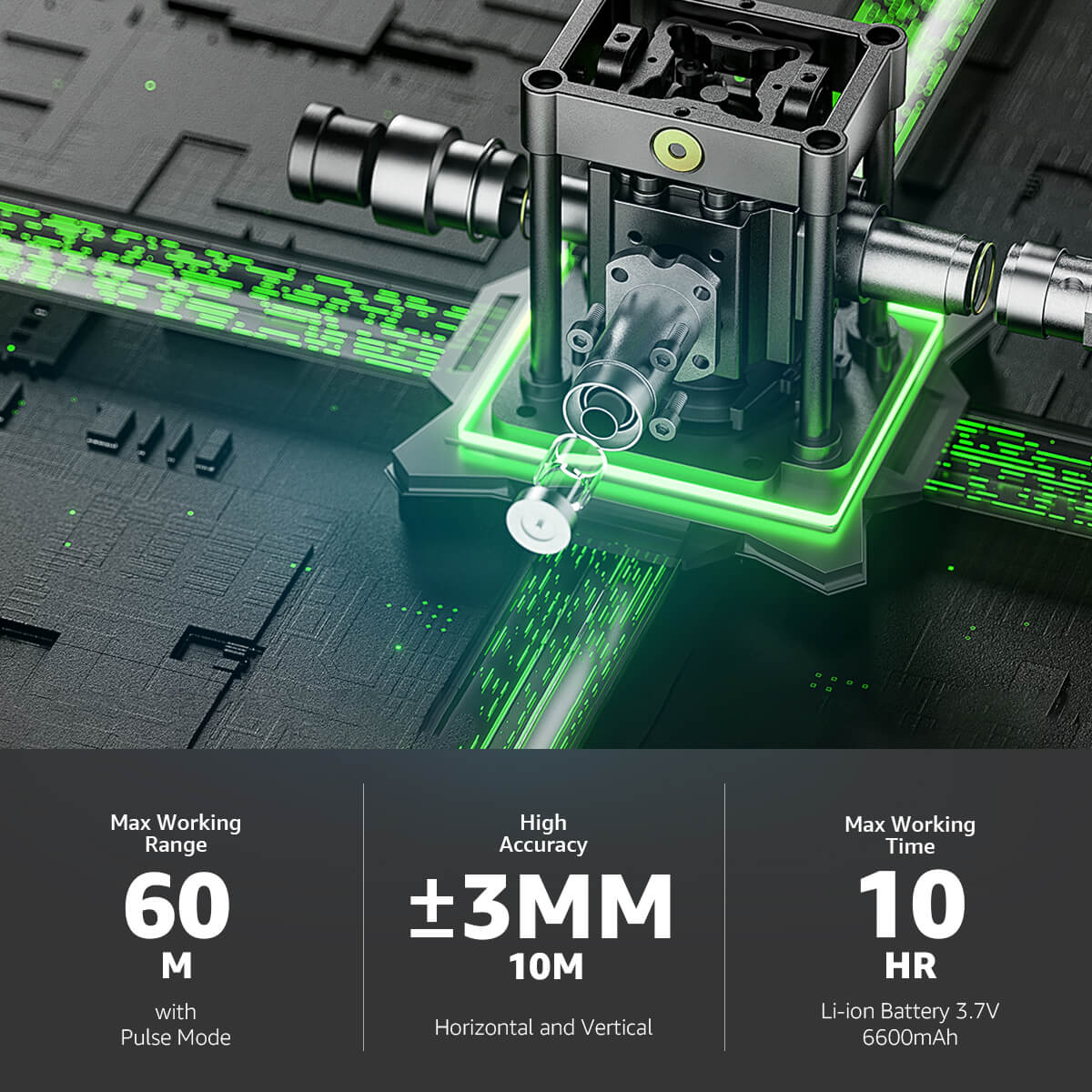

The laser level is a device that projects a laser beam to provide a reference line or plane for leveling and aligning applications. It uses a laser diode, which provides an extremely bright, focused beam of light that is quite visible even under well-lit conditions.

Laser levels work by projecting a laser beam to create a level line or plane. A diode creates the laser beam, which is then reflected off a series of lenses and mirrors that form it into a straight level line or a rotating plane. Most laser levels are self-leveling and can adjust themselves automatically to the correct level so that proper results can be produced.

Types of Laser Levels

There are several types of laser levels available, each designed for specific applications:

-

Line Laser Levels: These project a single laser line either horizontally or vertically and come in very handy when hanging pictures or aligning cabinets and tiles.

-

Dot Laser Levels: These types project several dots, usually one horizontal and two vertical, through which some layout and alignment can be achieved.

-

Rotary Laser Levels: Project a rotating laser beam to form a level plane. In that case, these laser levels can be applied for bigger projects involving concrete pouring, grading, and landscaping.

-

Combination Laser Levels: These lasers can project both laser lines and dots and provide several layout and alignment solutions from one tool.

Among the many advantages of using a laser level over other traditional methods, such as spirit levels or chalk lines, are that it is more accurate, easier to use, and covers more area with greater efficiency. Laser levels eliminate the need for manual leveling and provide a clear, visible reference line or plane. This reduces the possibility of errors and enhances productivity at a construction site or on a home improvement project.

Calibrating the Laser Level

Calibration of a laser level is important for accurate and reliable measurements. Even the best laser levels can get misaligned with time due to drops, bumps, or temperature changes. Proper calibration ensures that the laser beam is truly level or plumb for precise reference points and elimination of errors.

Calibration of a laser level is different with various types and models. In the case of line laser levels, calibration usually consists of the adjustment of a laser diode to align horizontal and vertical beams. In the case of rotary laser levels, the rotating laser beam should be calibrated to spin perfectly level. Many manufacturers have their specific guidelines on how to perform calibration with their products.

Generally speaking, laser levels should be calibrated before every major project or any time they may have experienced an impact or jarring. For construction professionals who depend on laser levels, monthly and quarterly calibration checks are recommended. Regular calibration preserves the integrity of the laser level's accuracy for consistent results, preventing costly mistakes on the job site.

How to Use a Laser Level for Floors?

Preparing for Floor Installation

The preparation of a laser level before application on the floor is very important. This is to ensure leveling is accurate and precise to avoid any costly mistakes down the line. Following are the key steps to follow:

-

Clean the Floor Area: Make sure the floor surface is clean of all debris, dust, or any obstacle that might interfere with the path the laser beam will travel and affect the accuracy of the measurements.

-

Ensure a Stable Surface: The subfloor or existing floor should be checked for stability and not have any major cracks, bumps, or unevenness. A stable surface is important for accurate leveling and to avoid any problems during the installation of the flooring.

-

Set the Laser Level Height: The laser level is set to a height representing the type of flooring to be installed, including the finished floor level. That would be a height considering the thickness of the flooring material plus whatever underlayment or leveling compounds may be required.

-

Check for Obstructions: Look around the room for any possible obstructions that may impede or obstruct the projection of the laser beam. Move or remove furniture, equipment, or any other objects that could block the path of the laser beam to ensure a line of sight throughout the installation area.

In these preparatory steps, you provide a good platform upon which a laser level is optimally utilized for minimizing error while having a successful and very accurate process of installing a floor.

Using a Laser Level for Floor Leveling

Proper positioning of the laser level is crucial for accurate floor leveling. Here are the steps to follow:

-

Position the Laser Level: Set the laser level in the middle of the room on firm and leveled ground, or on the raising base. It must be set at a reasonable height that best serves the working at hand.

-

Allow Self-Leveling: Switch on the laser level, allowing it to self-level. Most of the latest laser levels can automatically self-level the laser beam perfectly either way: levelling or plumming.

-

Mark Reference Points: When the laser level self-levels, take the projected laser beam and mark reference points on the wall or floor. These will provide guidelines through which the floor surface is leveled.

-

Check for Level: Determine if the floor surface is level by using the crosshairs or beam from the laser level. Move the laser level slowly around the room, observing the relationship of the laser beam to the floor surface. If the beam is not parallel to the floor, that surface is uneven.

-

Mark High and Low Points: Now, move the laser level to mark the high and low points where the laser beam intersects on the floor. These markings will give you the points that need leveling or grinding down.

-

Repeat and Verify: Repeat the process, moving the laser level to different positions within the room to ensure accurate and consistent measurements throughout the entire floor area. Double-check your markings and verify the level before proceeding with the flooring installation.

Following these steps and making use of the projected beam coming from the laser level will definitely provide you with an accurate identification of any high or low spots on the floor surface for a perfectly level foundation of your flooring installation.

Tile Layout with A Laser Level

The most important benefits of using a laser level in the installation of tiles are its projection of clear, precise laser lines across the floor area. These laser lines serve as visual guides, allowing you to achieve a perfectly square layout and ensuring that your tile rows remain straight and aligned.

First, place the laser level in the center of the room and turn the horizontal and vertical laser lines on. The point where these lines cross makes a reference pattern of the grid onto the floor. Move the laser level so that these lines perfectly square regarding the layout of the room.

Next, chalk the positions of tiles by guiding laser lines over them. Starting at the center of the room and working your way out, pull chalk lines or use a straight edge to transfer the position of laser lines onto the floor. What this will accomplish is perfectly straight and aligned rows of tile even over long spaces.

Additionally, the laser level's vertical laser line can be used to check for plumb walls and ensure that your tile installation starts and ends with a straight, vertical edge. This is particularly useful when working with intricate patterns or designs, as it helps maintain the integrity of the overall layout.

By using the accuracy of the laser level's projected lines, you will achieve a professional look with much less effort. The laser level removes tedious manual measurements and snapping chalk lines, freeing up more of your time and making sure your result is perfect and beautiful to behold.

Benefits of Using a Laser Level for Floors

There are several key benefits you can realize from using a laser level in floor installation as compared to other methods:

Increased Accuracy

Laser levels eliminate the guesswork and human error involved in using manual leveling tools, including spirit levels or string lines. This assures accurate laser beams to perfectly level the floors, avoiding uneven surfaces, lippages between the tiles, and other forms of compromise on the integrity and beauty of the finished floor.

Time Savings

With a laser level, one instantly draws reference points and level lines across the entire room or jobsite. This makes the layout and installation procedures that much simpler, saving a tremendous amount of time from the painful measuring and marking that is done manually.

Professional Finish

Self-leveling, tight grout lines, and transitions that blend seamlessly together equate to a very professional, polished appearance that adds great value to the overall look of the space. The laser level lets you achieve this high-end finish on every installation, even large or complex ones.

Reduced Rework and Costs

Most uneven floors need extensive rework, like removing and re-laying sections, adding a lot of labor costs. Using a laser level from the very beginning minimizes these costly mistakes, saves money on material waste, and saves extra labor hours. Pay for a good laser level once and enjoy the high productivity it offers by reducing wastes and reworks.