The Ultimate Guide to 3D Laser Levels: Enhancing Precision in Construction

Understanding Laser Levels: Types and Uses

Different Types of Laser Levels

Laser levels are a vital tool in many projects. They come in various types, each suited for different tasks. Here are some common ones:

- Dot lasers project simple spots on surfaces.

- Line lasers emit straight lines across a wall or workspace.

- Rotary lasers spin to create a 360-degree line around a room.

- Cross-line lasers, like 3D laser levels, project lines both horizontally and vertically.

- 4D laser levels take precision a step further, providing complete room coverage.

Each type offers unique benefits for construction and home DIY. Understanding these will help you choose the right tool for your job.

How Cross Line and 4D Laser Levels Work

Cross line and 4D laser levels are cutting-edge tools used in various settings. The cross line laser level projects two or more lines that intersect each other. They can give both vertical and horizontal reference points at once. This makes them ideal for tasks like installing wallpaper or tiling. On the other hand, 4D laser levels offer even more flexibility. They can cast a 360-degree horizontal or vertical plane. This means you can get a full room layout without moving the tool. These levels are great for complex projects, like setting up a grid for a dropped ceiling or framing out a partition wall. Both types use a laser diode to create bright, clear lines. These lines can be seen even in well-lit areas. As these tools have different capabilities, it's important to choose the right one for your project to enhance your accuracy and efficiency.

Practical Applications in Construction and DIY

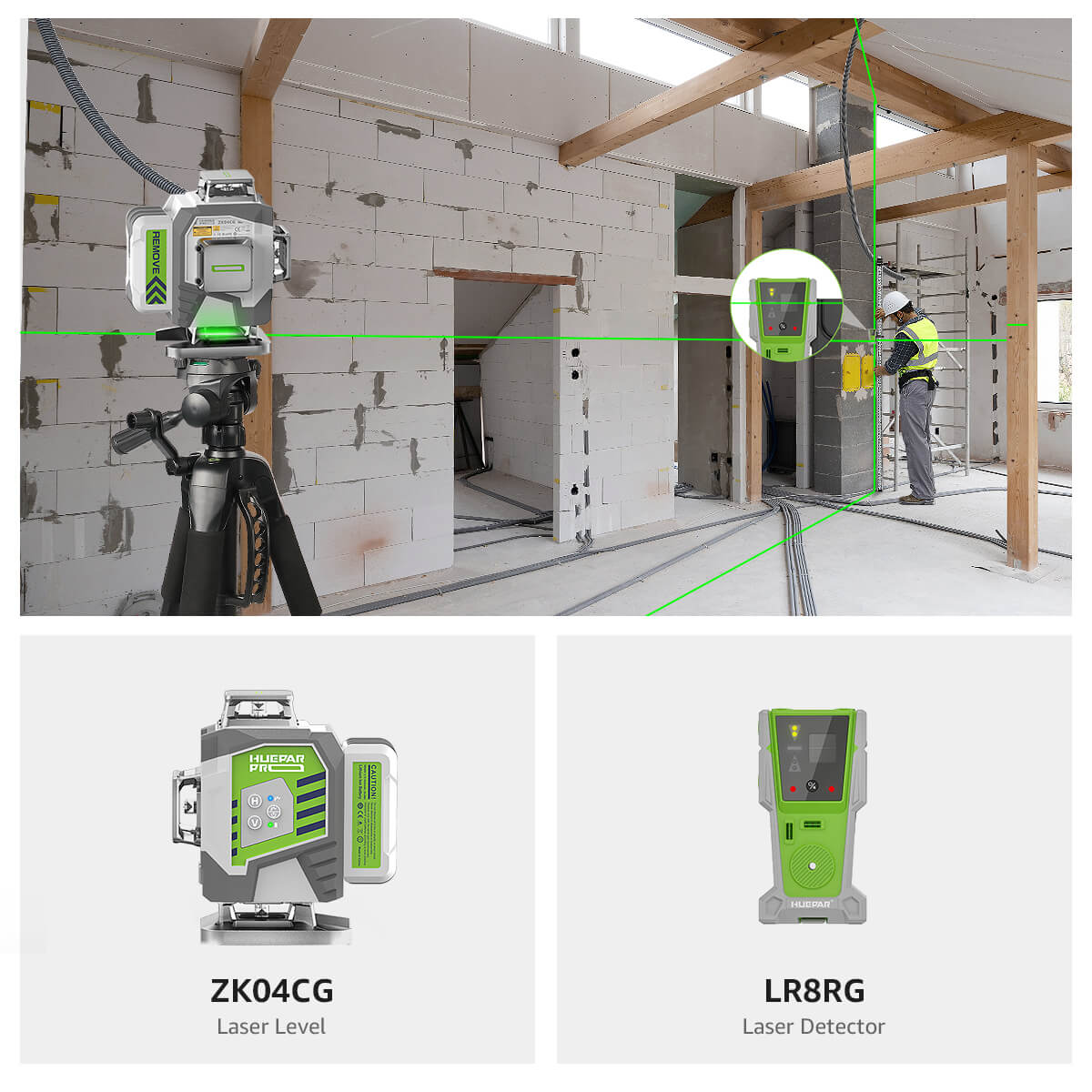

- Constructing Walls and Partitions: 3D laser levels help ensure walls are straight and corners are square.

- Installing Ceilings and Floors: They provide a level reference, which is crucial for laying tiles or flooring evenly.

- Mounting Shelves and Cabinets: These laser levels project accurate lines for alignment, making sure these fixtures are level and plumb.

- Aligning Pipes and Electrical Conduits: For precise installations, 3D lasers offer clear guidance for runs.

- DIY Projects: They're great for home projects like creating photo walls or painting accent walls with straight lines.

Key Features to Consider When Choosing a 3D Laser Level

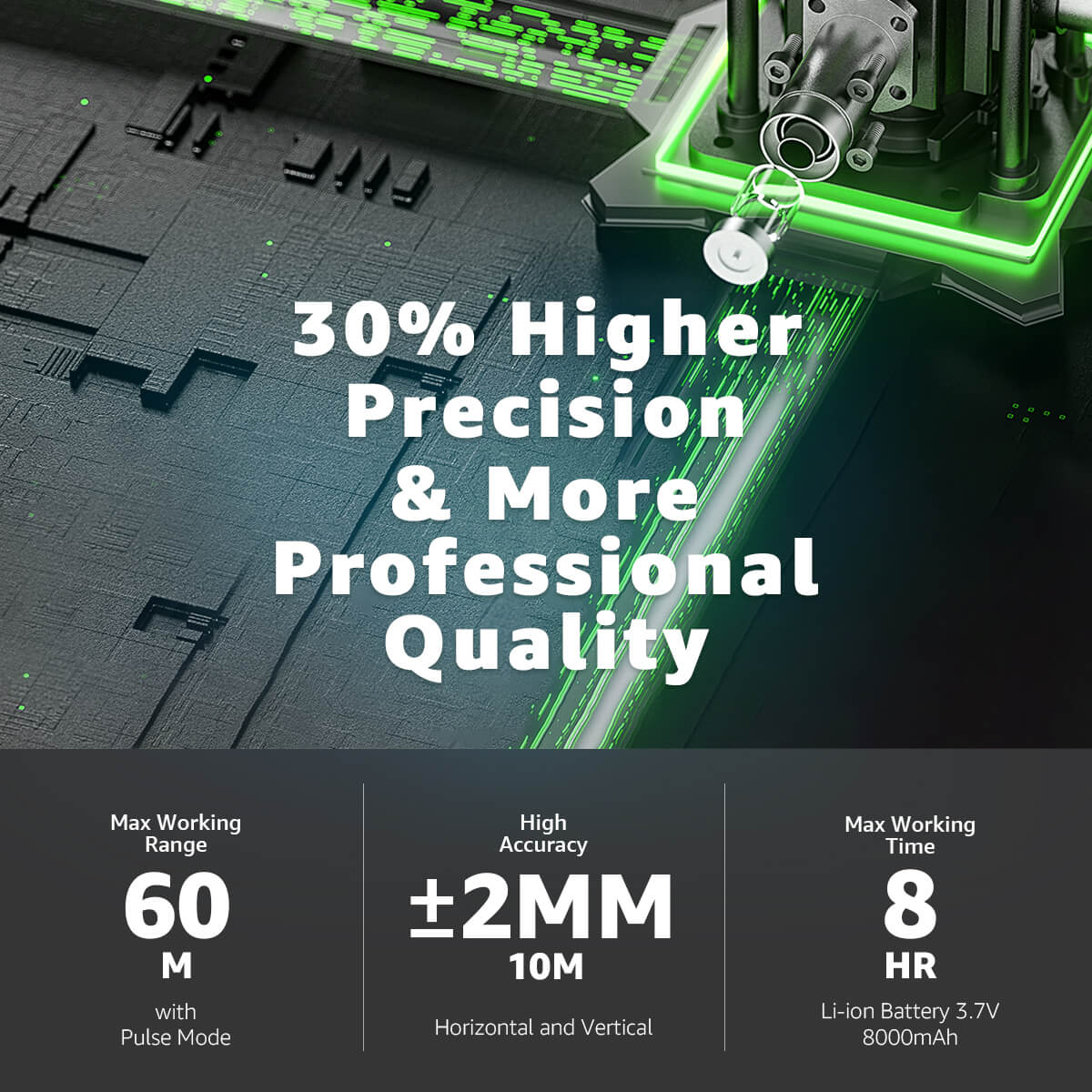

Accuracy and Precision

When selecting a 3D laser level, accuracy is vital. Look for options with a high degree of precision. This ensures your measurements are spot on. Also, consider the level's self-leveling capability. This feature allows the device to auto-adjust for exact lines. Some levels offer a fine-tuning knob. It helps you align the laser with greater precision. Check the accuracy rating, usually in millimeters per meter. A smaller number means a more precise tool. Also, see how the device performs over long distances. Good accuracy at range is a must for large projects.

Durability and Construction

- Robust Housing: Seek a design that can withstand the job site's bumps and knocks.

- Water and Dust Resistance: Check for an IP rating to ensure the laser level handles varied environments well.

- Mounting Options: Look for models with multiple mounting choices like tripods or brackets for versatility.

- Stable Calibration: Opt for construction that maintains calibration despite everyday wear and tear.

- Warranty: A longer warranty period can be a sign of the manufacturer's confidence in the product's durability.

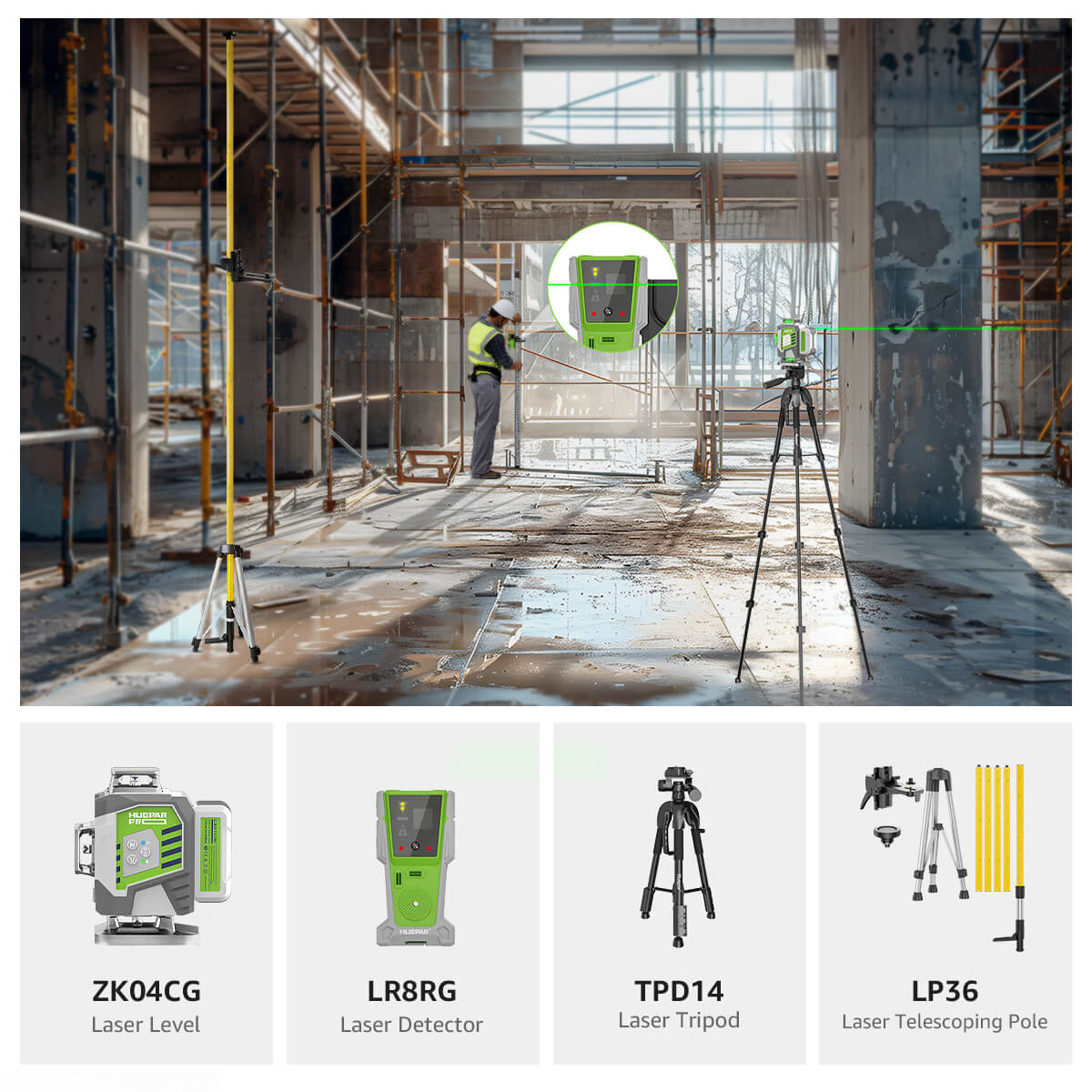

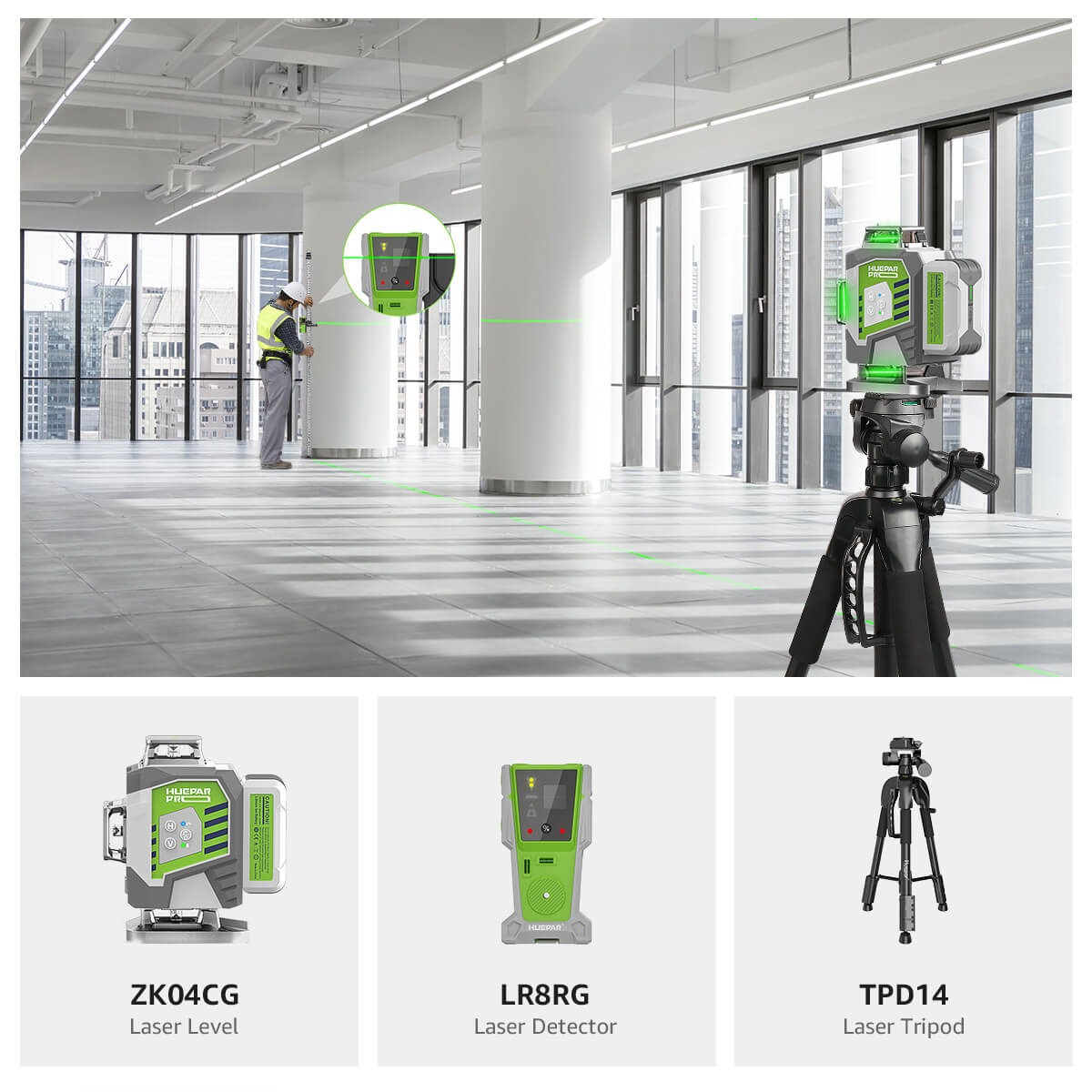

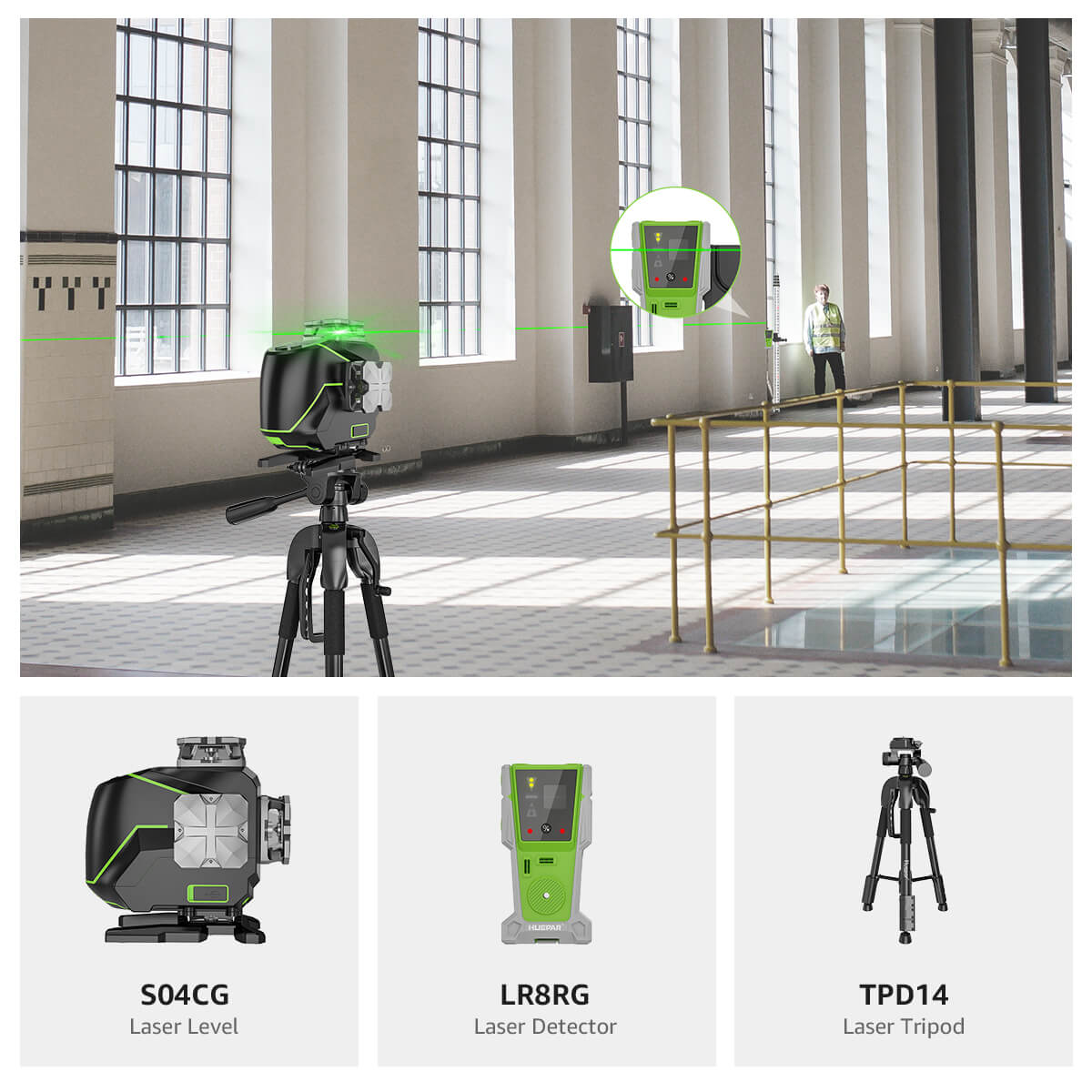

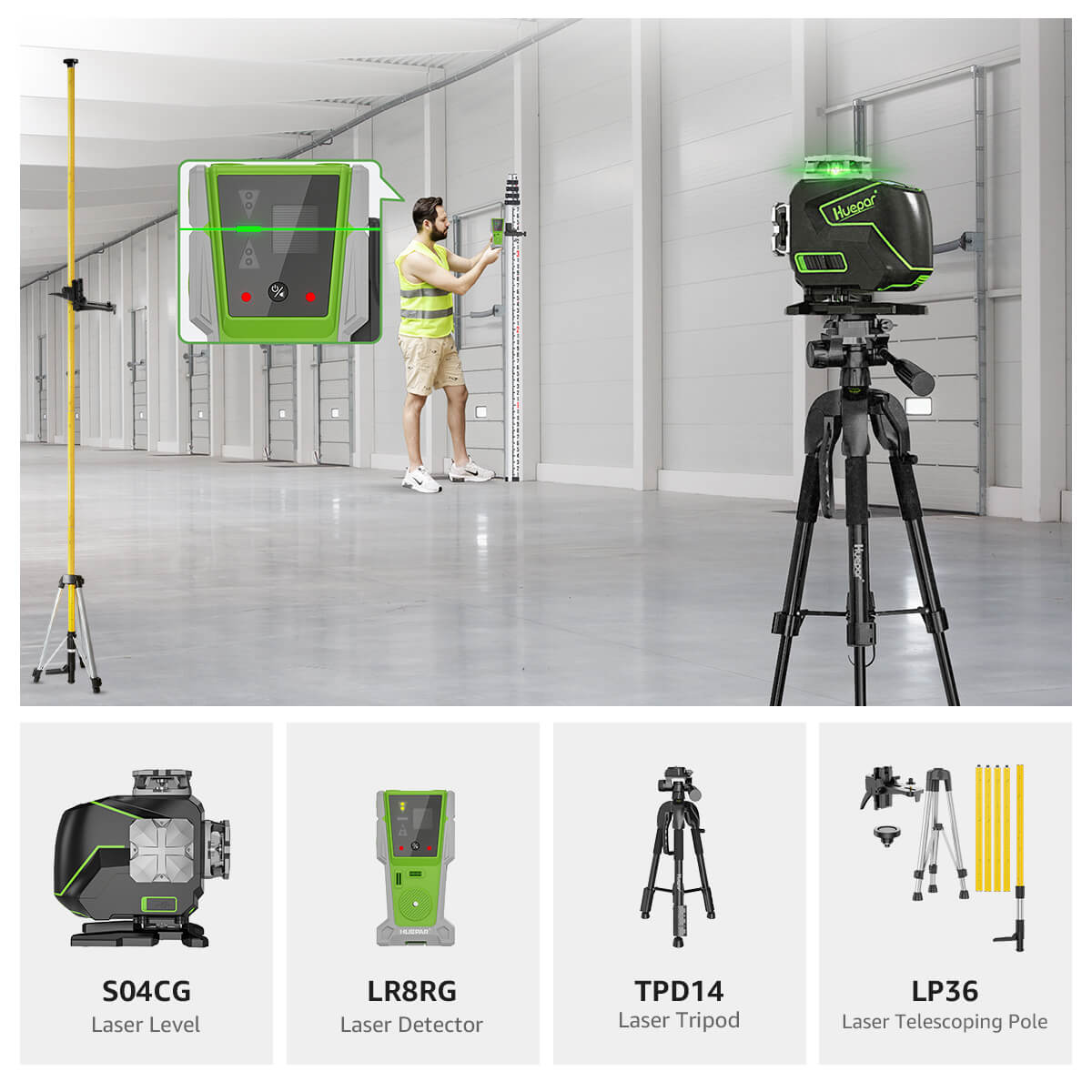

Additional Features and Accessories

When selecting a 3D laser level, consider extra features and add-ons:

- Self-leveling capability: This feature allows the laser level to automatically align itself within a certain range, which can greatly enhance ease of use and accuracy.

- Laser detectors: Also known as receivers, they help to locate the laser lines in bright conditions or over long distances where the beams may be difficult to see.

- Battery life and power options: Look for models with long-lasting batteries or the ability to use rechargeable packs to ensure uninterrupted work.

- Mounting devices: A good 3D laser level should come with various mounting options like brackets, magnets, or tripods to suit different job site conditions.

- Remote control: With a remote, you can operate the laser level from a distance, making it convenient for single-person jobs.

- Protection features: Consider levels with padded carrying cases or dust and water-resistance to extend the lifespan of the device.

These additional features can greatly influence the versatility and functionality of your 3D laser level.

Best Practices for Using 3D Laser Levels in Construction

Setting Up the Laser Level for Optimal Performance

To get the best from your 3D laser level, a good setup is key. Start with these steps:

- Choose a stable surface. Make sure it's level and firm.

- Check the laser level's calibration before use to ensure accuracy.

- Adjust the leveling feet or tripod so the device is perfectly horizontal or vertical.

- Turn on the self-leveling feature if your model has one. This makes setup easy.

- Clear the area of any obstacles that might block the laser's path.

- For outdoor use, pick a time with low light conditions to see the laser better.

These steps will help you achieve the best results and maintain the 3D laser level's performance.

Tips for Maintaining Accuracy Over Time

To keep your 3D laser level accurate, follow these tips:

- Calibrate Regularly: Check the calibration according to the manufacturer's instructions. This ensures precise measurements.

- Handle with Care: Avoid dropping or jostling the laser level. Treat it as a precision tool.

- Clean Optics: Keep the laser diode and lens clean. Dirt affects the laser's accuracy.

- Store Properly: When not in use, store it in a protective case. This keeps the tool safe and precise.

- Battery Check: Use fresh batteries or fully charge them. Low power can decrease accuracy.

- Avoid Extreme Temperatures: Exposure to intense heat or cold can impact laser performance. Store and use the level in recommended conditions.

By keeping these tips in mind, your 3D laser level will remain a reliable tool for any project.

Safety Precautions When Using Laser Levels

When using 3d laser levels, safety is crucial. Always wear protective eyewear to shield your eyes from laser exposure. Never aim the laser at anyone's face or eyes, as the intense light can cause damage. Be aware of your surroundings. Make sure that no one enters the laser's path accidentally. Also, it is essential to avoid using laser levels near reflective surfaces. These can redirect the beam unpredictably, posing a risk. Lastly, always follow the manufacturer's guidelines and use the equipment as intended. Care in use will keep you and others safe on the job site.