All You Need to Know About 3D Laser Levels: The Ultimate Guide

Introduction to Laser Levels

Understanding the Basics of Laser Levels

Laser levels are tools that project a straight line onto a surface. They help ensure accuracy in various tasks, such as hanging pictures or building walls. Levels come in different types, like 2D, 3D, and 4D, to suit different needs. Each type has unique features and benefits for specific jobs.

The Evolution of Laser Level Technology

Laser level technology has advanced greatly over time. Early tools were simple and manual. But now, we have precise and automatic laser levels. The change began with 2D laser levels that project lines on flat surfaces. Later, 3d laser levels arrived, displaying lines across three planes. This allowed for full-room layout with just one tool. Recently, 4D laser levels have emerged, adding more lines for even greater accuracy. The cross line laser level remains popular for its simplicity. As tech improves, these tools become more user-friendly and accurate. This growth in laser level tech has changed how construction and other industries work.

Types of Laser Levels: From 2D to 4D

Laser levels have evolved over time, offering more precision and features. We can group them into several key types:

- 2D Laser Levels: These are the simplest form, projecting one or two fixed lines onto a surface.

- Cross Line Laser Levels: These project two lines, one vertical and one horizontal, to form a cross on the surface.

- 3D Laser Levels: These advanced levels project lines in three dimensions, giving a full room layout.

- 360-degree Laser Levels: These emit a level line in a 360-degree circle around the device.

- 4D Laser Levels: The latest innovation, featuring 360-degree projection in both vertical and horizontal planes, for a complete room grid.

From simple 2D to sophisticated 4D models, the progression in laser level technology caters to a wide range of needs in construction and alignment tasks.

Unveiling the Features of 3D Laser Levels

How 3D Laser Levels Work

3d laser levels are precision tools that project visible beams onto surfaces. They create accurate 3D crosshairs. This means you get vertical and horizontal lines at the same time. They help users align and level objects with ease. Two beams are at 90 degrees to each other. It makes an X, Y, and Z axis in the space. A 360-degree emitter is often used. This lets the laser reach all parts of a room. There's usually a self-leveling feature. This keeps the lines straight, even if the base isn't flat. Modern 3D lasers can be connected to smart devices. They can be controlled and have their settings changed using an app.

Advantages of Using 3D Laser Levels in Construction

- Precision and Accuracy: 3D laser levels project accurate lines on all X, Y, and Z axes. This lets workers set out plans to exact specs with less effort.

- Time-Saving: These levels help complete tasks faster. This is because you don't need to double-check the work. The laser ensures accuracy the first time.

- Versatility: They suit indoor and outdoor projects. Whether you're setting up walls, pipes, or large structures, 3D levels are flexible.

- User-Friendly: Most models come with simple controls. They are easy for most workers to use after a brief training.

- Reduced Errors and Corrections: With better accuracy, the need for redoing work drops. This saves on costs and materials.

- Enhanced Communication: When all workers use the same precise tool, it's easier to follow plans. This avoids miscommunication on site.

- Improved Safety: Using 3D laser levels can reduce the time workers spend on ladders. This drops the risk of falls and injuries.

Comparing 3D, 4D, and Cross Line Laser Levels

When selecting a laser level, it's key to compare the different types available. 3d laser levels project lines in three planes, offering a 360-degree coverage which is great for tasks requiring precise alignment on walls and floors. Cross line laser levels, on the other hand, emit cross-sectional lines on a surface and are perfect for basic home renovations or installations. Meanwhile, 4D laser levels offer an extra plane of projection. This gives a full room layout without repositioning the level. In simple terms, a 3D level covers length, width, and height. A cross line handles two planes at once. And, a 4D level adds rotating capabilities that give a full room layout from one spot. Consider the scope and precision needed for your project when choosing between these tools.

Practical Applications and Choosing the Right Laser Level

The Use of 3D Laser Levels in Various Industries

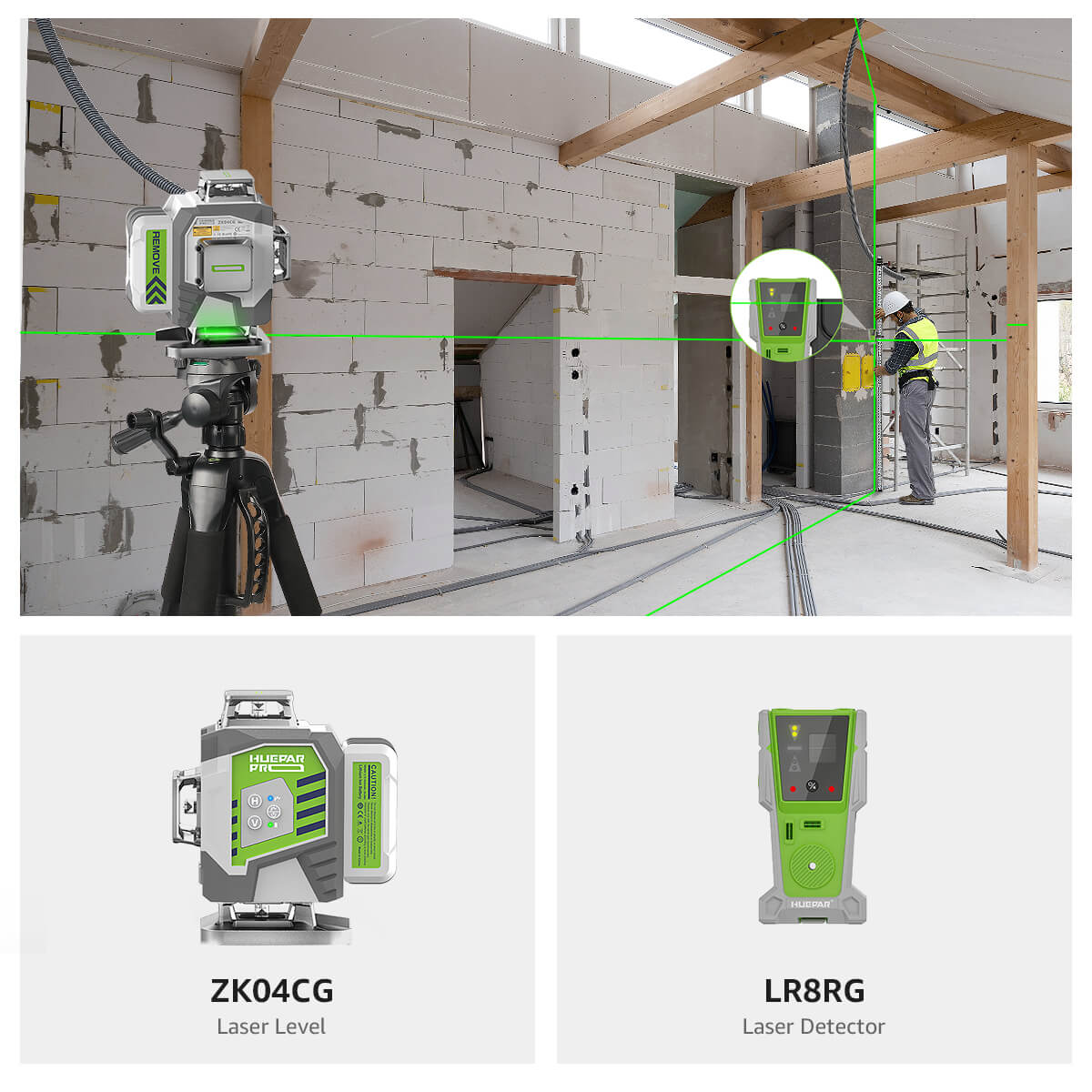

- Construction: Streamlines the process of leveling and alignment, saving time and reducing errors.

- Carpentry: Essential for ensuring structures are level and true, from cabinets to frameworks.

- Architecture: Aids in the accurate transfer of design plans to physical sites.

- Interior Design: Assists in the alignment and installation of wall decorations, shelves, and lighting fixtures.

- Manufacturing: Useful for setting up machinery and checking product alignment.

- Plumbing: Helps in installing pipes and fixtures perfectly horizontal or vertical.

Tips for Selecting the Best 3D Laser Level

Selecting the best 3D laser level can be tricky. Follow these tips:

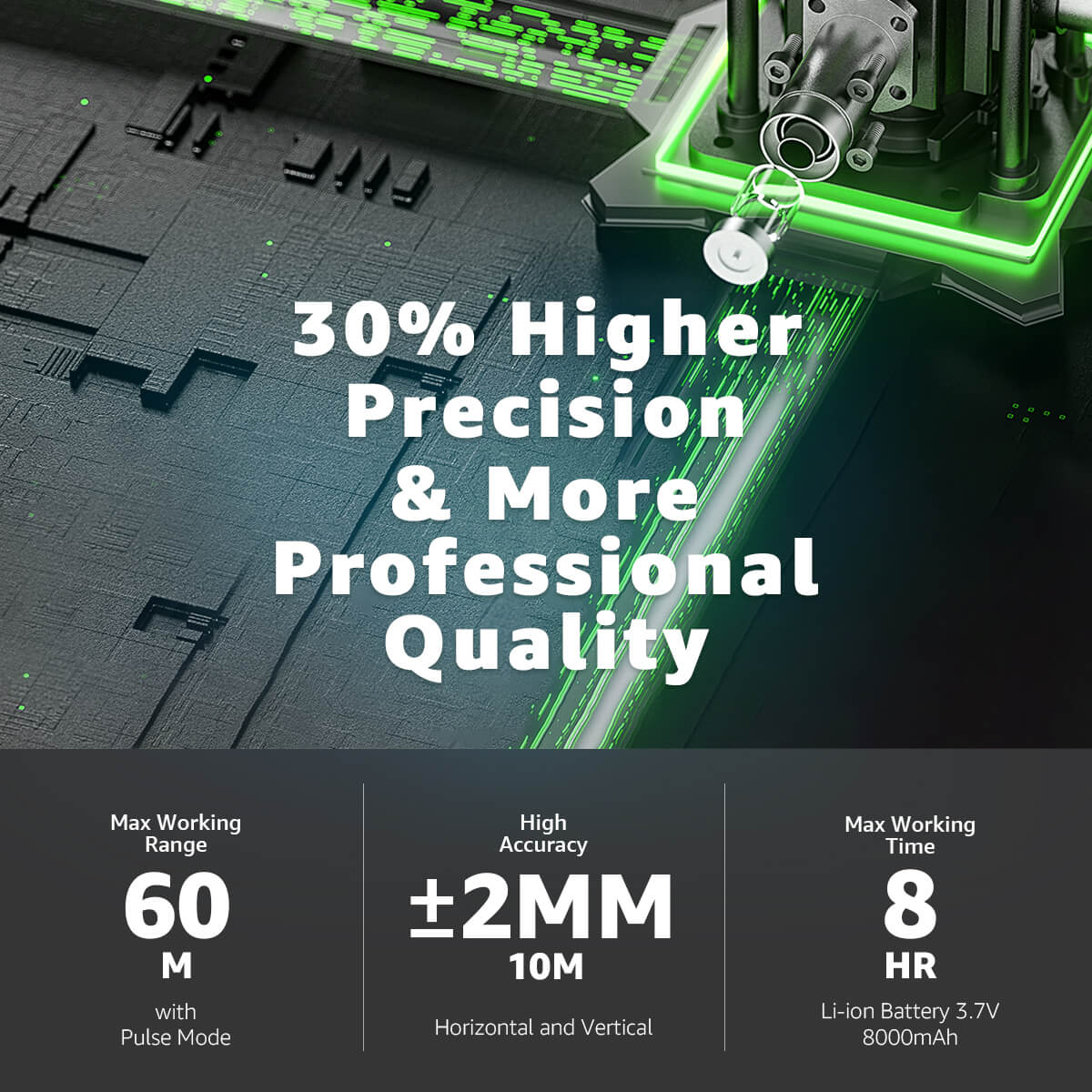

- Consider Accuracy: Check the spec for precision.

- Durability Matters: Look for robust construction.

- Battery Life: Longer battery means less downtime.

- Ease of Use: User-friendly interfaces save time.

- Mounting Options: Ensure it has versatile mounting.

- Beam Visibility: Bright beams are better in daylight.

- Price vs. Quality: Balance costs with features needed.

- Brand Reputation: Pick brands known for reliability.

- Warranty: A good warranty offers peace of mind.

- Reviews and Ratings: See what others say about the tool.

Choose wisely to ensure your 3D laser level meets your needs.

Maintenance and Safety Precautions for Laser Levels

- Regularly check the calibration to ensure accuracy.

- Avoid exposure to water and dust by using protective cases when not in use.

- Follow the manufacturer’s guidelines for cleaning and storage.

- Keep laser levels away from extreme temperatures to prevent damage.

- Handle with care to avoid drops or impacts that can misalign components.

- Replace batteries or charge regularly to maintain optimal performance.

- Use laser glasses to protect eyes when operating the device.

- Do not attempt to disassemble or repair the laser level yourself.

- Ensure that bystanders are aware of the laser during operation to prevent eye damage.

- Store the laser level in a secure place to prevent unauthorized use.