Construction Laser Level Buying Guide 2025

Most laser levels on the market are designed to be used by construction professionals, but they can also be very useful to the amateur handyman.That’s why it’s important to choose the right construction laser level before you invest your money in one. When making this decision, it’s crucial to consider your budget, the size of your project, and even the quality of customer service you can expect from the manufacturer or seller.This construction laser level buying guide will help you make an informed decision about which laser level you need for your specific building needs, as well as how to use your new equipment and keep it properly maintained so that it lasts you many years to come.

What is a construction laser level?

Construction laser levels are used in construction, architecture and building to ensure that structure is built on level ground. This tool uses a laser to show how far off level an object or surface is at any given moment.

A construction laser level can be used by workers and contractors when dealing with huge structures as well as small projects, such as furniture installation and shelves. Construction lasers come in many different types and prices, making it difficult for buyers to choose one without doing research first. Continue reading for more information about construction laser levels and how to find one that best fits your needs.

Construction laser levels vs. traditional surveying equipment

What's better, a laser level or traditional surveying equipment? The answer depends on what you're doing and what type of project you're working on. Laser levels are commonly used in new construction projects to ensure straight lines and right angles.

In addition, they make fast work of creating circles and other curves. Many contractors also use laser levels for placing cabinets, laying tile, framing walls and hanging mirrors during a remodel job. Because these devices are self-leveling – that is, they automatically adjust to an uneven surface – traditional surveying equipment isn't needed.

However, when accuracy is critical – when building or remodeling bridges or tall buildings where every degree of tilt can mean thousands or even millions in repairs – professional surveyors still use traditional tools like total stations.

Laser levels are very popular in construction and remodeling jobs because they can be used to quickly get a rough level surface. Traditional surveying equipment – sometimes called theodolites or transits – are more accurate, but they are also generally larger and heavier, require more setup time, cost significantly more and cannot self-level if a surface is not perfectly flat.

In contrast, a laser level can self-level so it doesn't need any additional accessories or fixtures to use on an uneven surface.

To learn more about laser levels for sale , visit our website today!

How to choose the best one

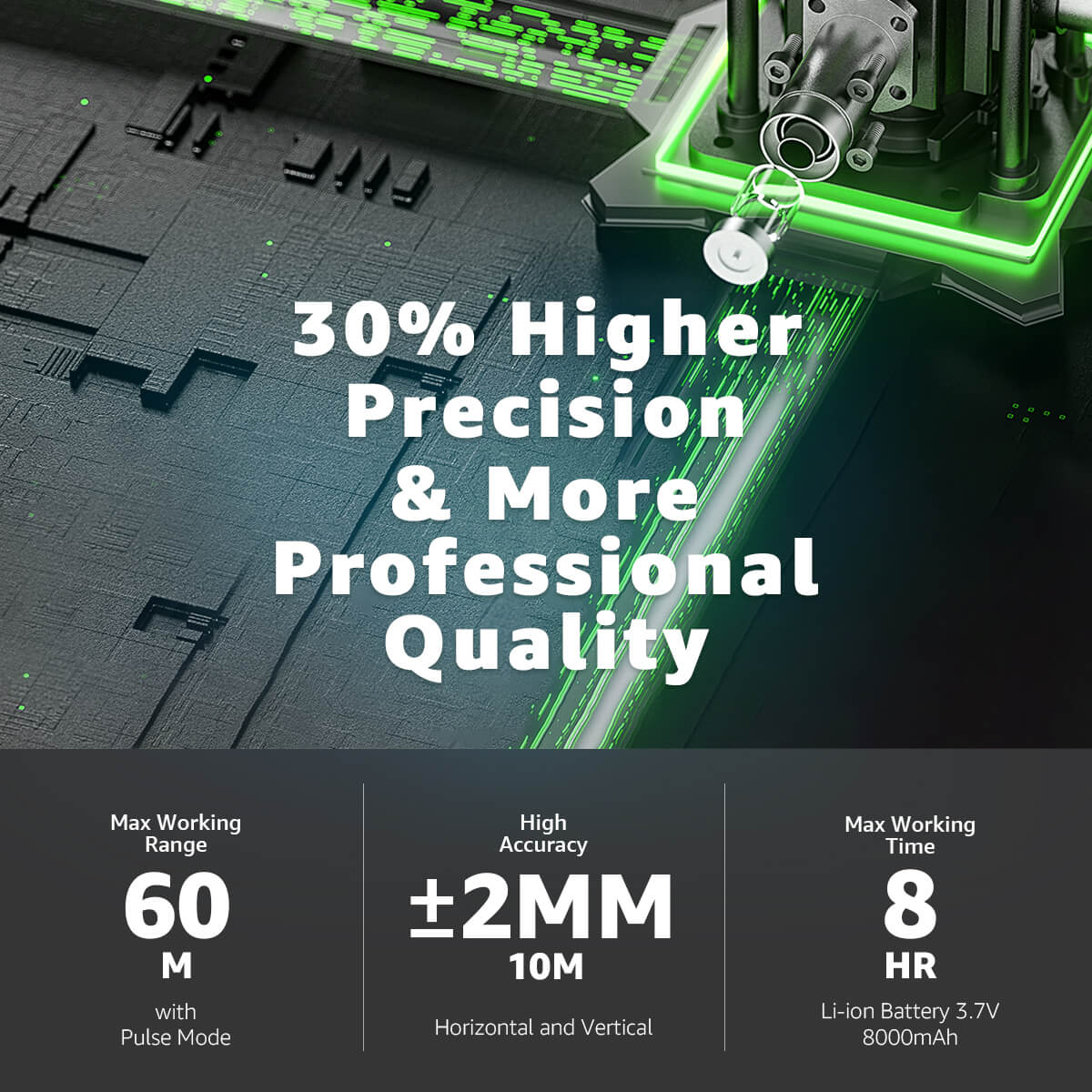

Accuracy: One of your top priorities should be accuracy. You don’t want to build a house on an uneven foundation, and you won’t want to miss any details when you’re building cabinets or laying tile. Look for a laser level that has at least 1/8th-inch accuracy. Some models have 0.001-inch accuracy, which is even better.

Durability: If you’re going to be working on a construction site, you need a laser level that can stand up to bumps and drops. Look for a model that is made of metal or durable plastic, rather than cheap plastic.

Usability: The best laser level are always easy to use. You should be able to adjust them quickly and easily, without having to fiddle with dials or buttons. Look for a model that has a locking mechanism so you can keep it in place as you work. The best models also have an automatic shutoff feature that turns off your laser level after 15 minutes of inactivity, which helps save battery life. A long-lasting battery is essential; most models will last for at least 10 hours before they need to be recharged.

Outdoor application: If you’re going to be using your laser level for construction, look for a model that is waterproof and weatherproof. It should also have an IP rating of at least 67. This means it can withstand exposure to dust and water.

Manual/Automatic: Some laser levels are manual, which means you have to hold them in place while you’re working. This can be difficult if you’re trying to use it on a roof or on uneven ground. Automatic models feature an attached tripod that allows you to set your laser level and walk away.

What is the difference between a laser level and a spirit level?

A laser level and a spirit level both enable you to achieve straight lines while you’re working on a construction project, but they do so in different ways. Spirit levels rely on physics: You need to place them on an even surface, fill them with liquid, and adjust them until they’re completely balanced horizontally. A laser level provides horizontal balance without needing to fill it with anything—it uses small lasers to guide your adjustments.

Where can you find a high quality builders level?

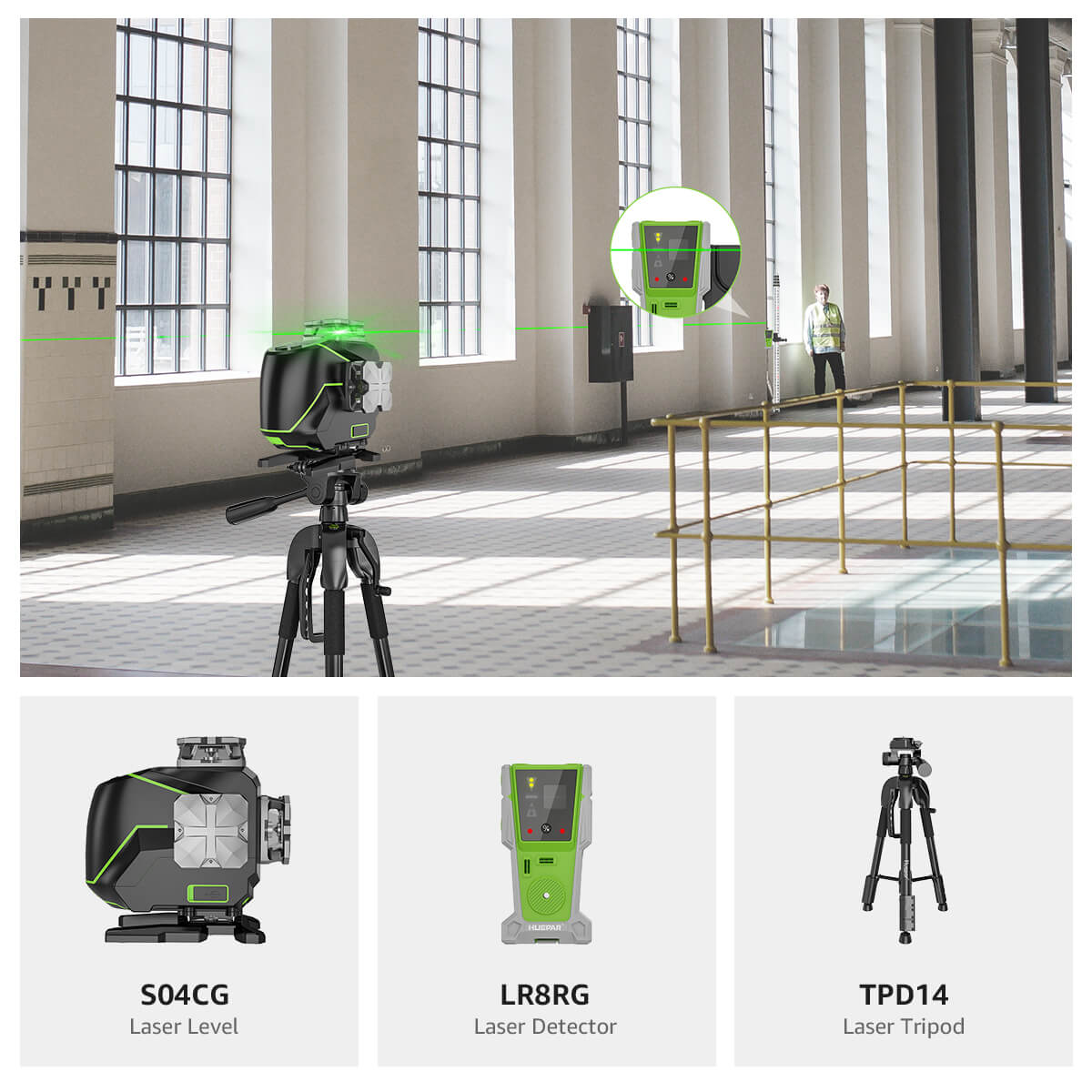

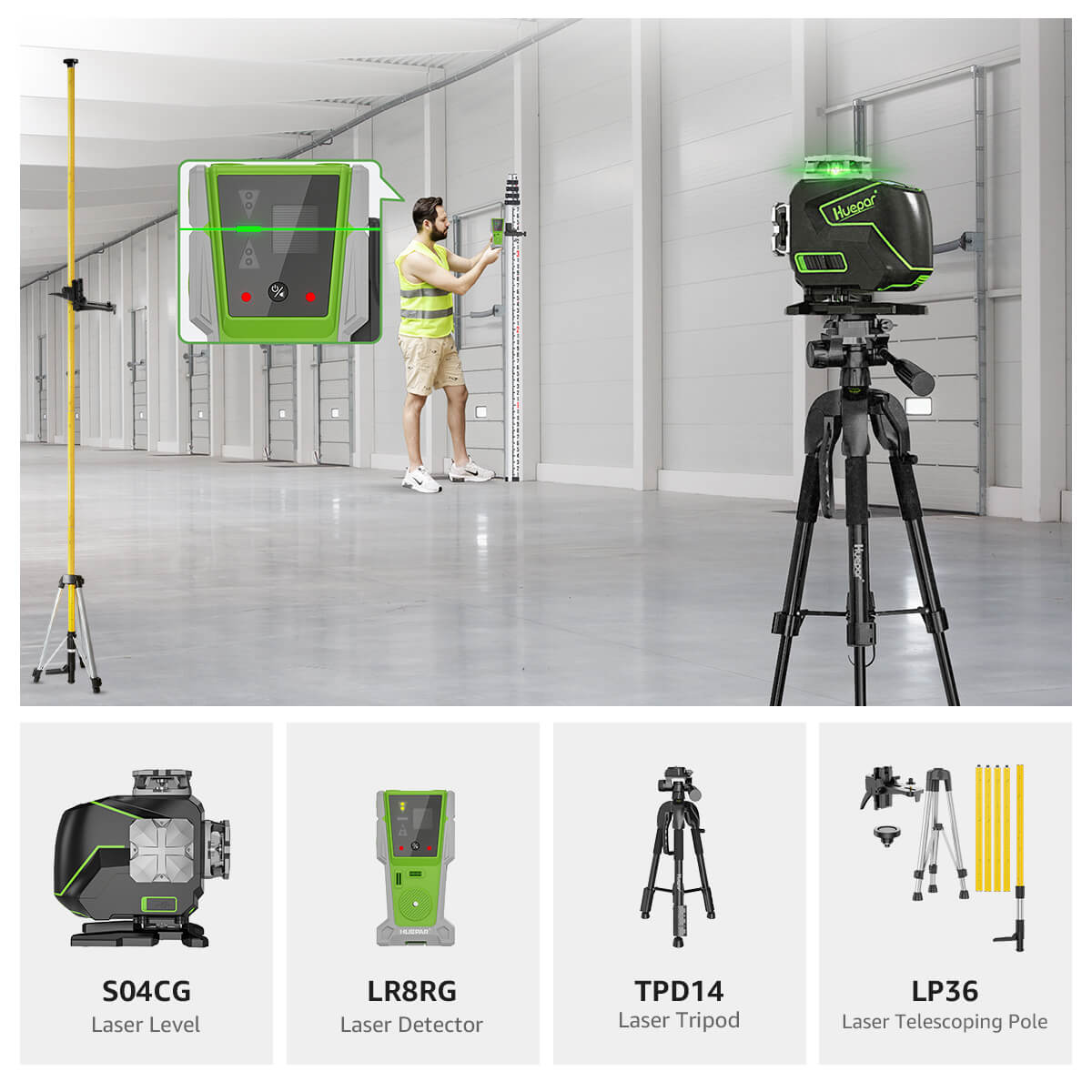

To find a reliable and high quality builders level, you can check Huepar official website. Huepar has a wide range of construction laser levels for sale with competitive price. The customer service is excellent and fast. You can contact them via E-mail or phone if you have any question on any product they sell. Hope you enjoy your shopping!

What are the best types of laser levels to use in construction?

Different laser levels are designed for different types of projects, but when it comes to construction, you’ll probably want a rotary laser. Rotary lasers allow you to make short work of long runs and are easier to handle than dot lasers. While they might be more expensive, rotary lasers have a lot of benefits—especially in a profession where time is money.

Combination lasers have all-in-one design that eliminates extra components, making them easier to handle on site; they also provide both level and plumb information at once. Dot lasers require less energy than other laser levels and can be transported from job site to job site without worry, thanks to their lightweight design.