How to Use a Laser Level for Grading?

A laser level is an accurate device that emits a laser beam to create a reference line or plane, thus allowing levels to be transferred. It's a very useful instrument for construction, landscaping, and other project grading and leveling jobs. Grading in construction involves the art of shaping the ground surface to a wanted slope or level, which is important for drainage, erosion control, and having a stable foundation for structures or landscaping elements.

Grading with a laser level will enable you to correctly establish and maintain precise elevation changes over an extended area. You won't need any time-consuming, labor-intensive manual leveling, and this will provide a very reliable, consistent reference point. This way, you'll be able to grade surfaces efficiently, allowing for proper water flow without any pooling, while reaching the intended slope or level that your project specifications require.

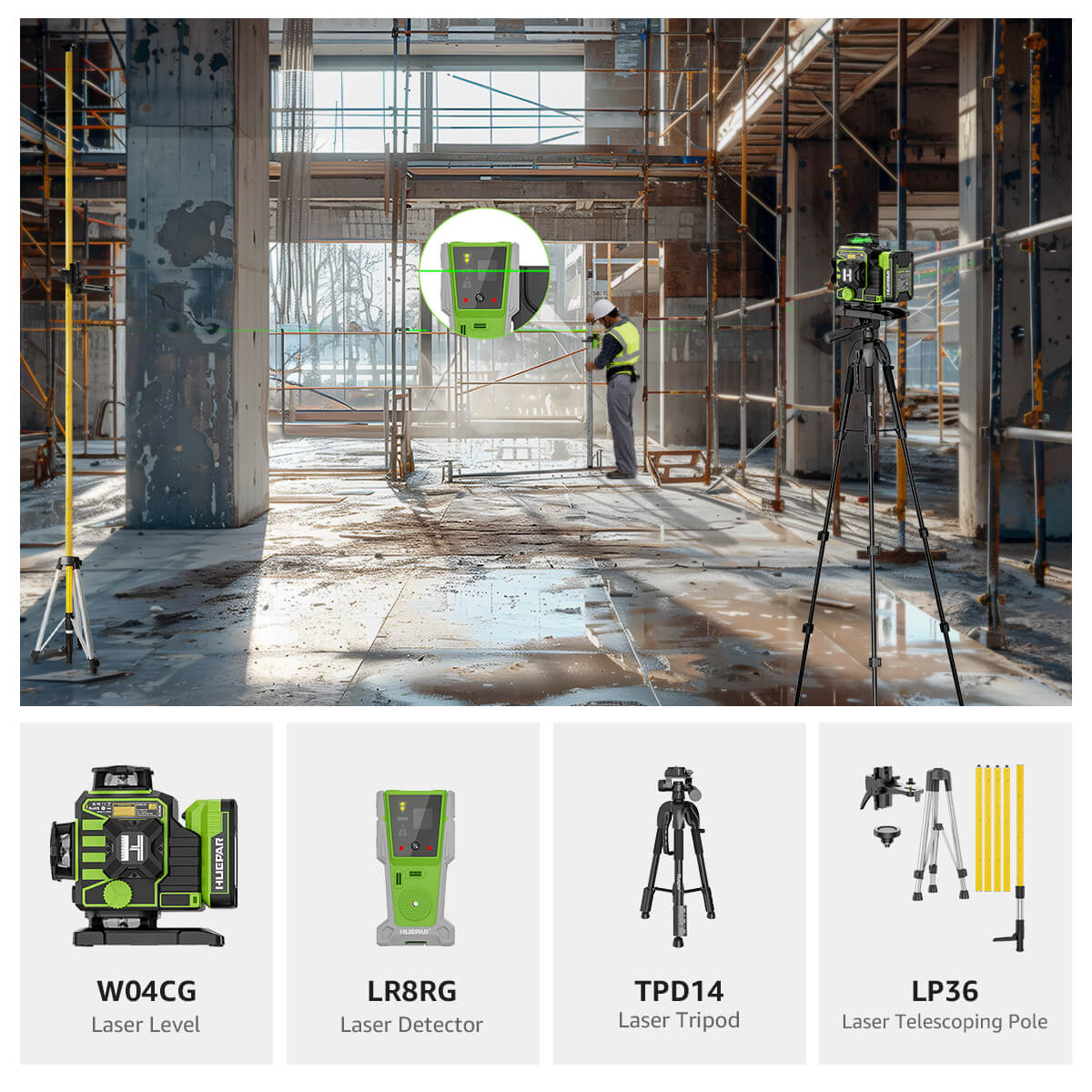

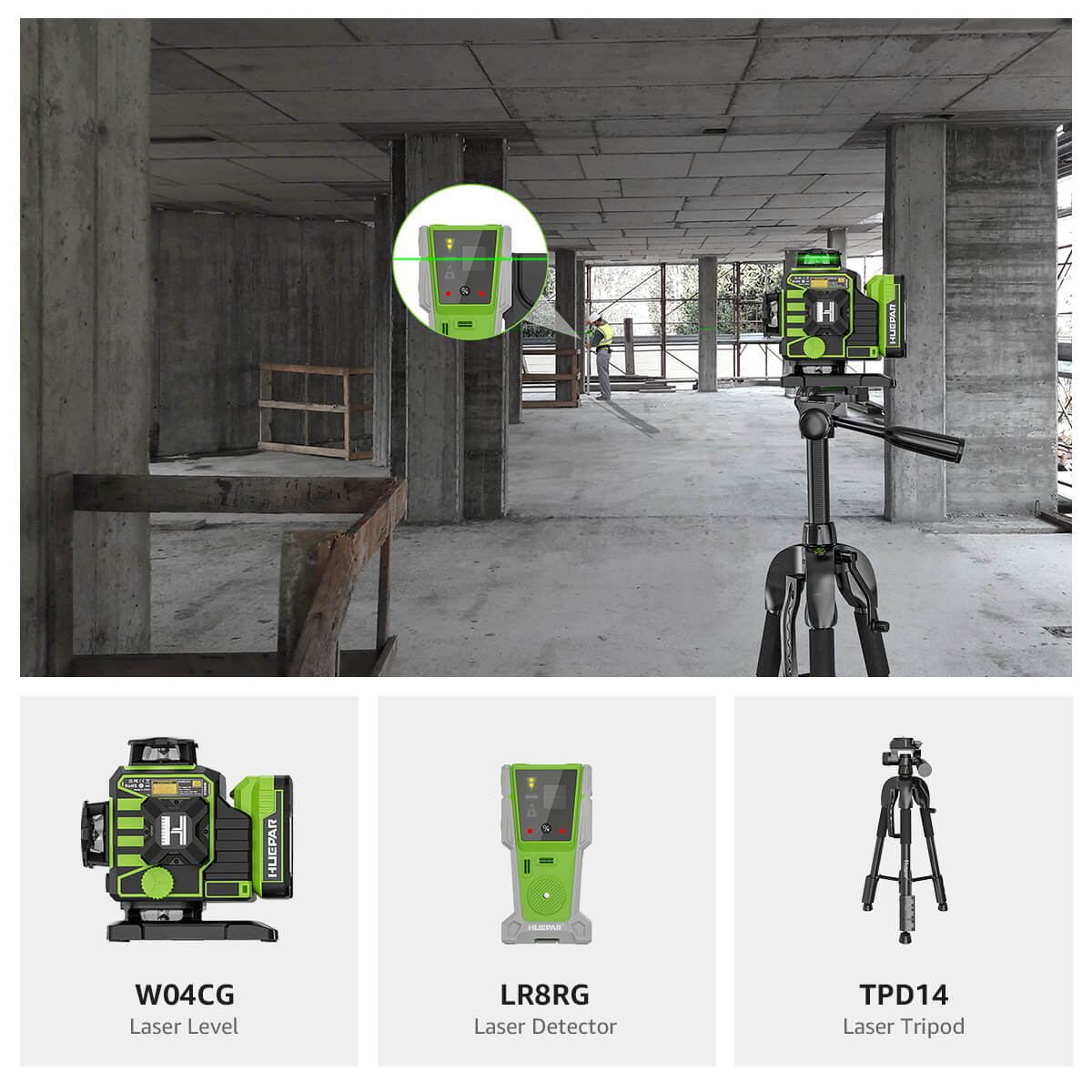

Tools Needed

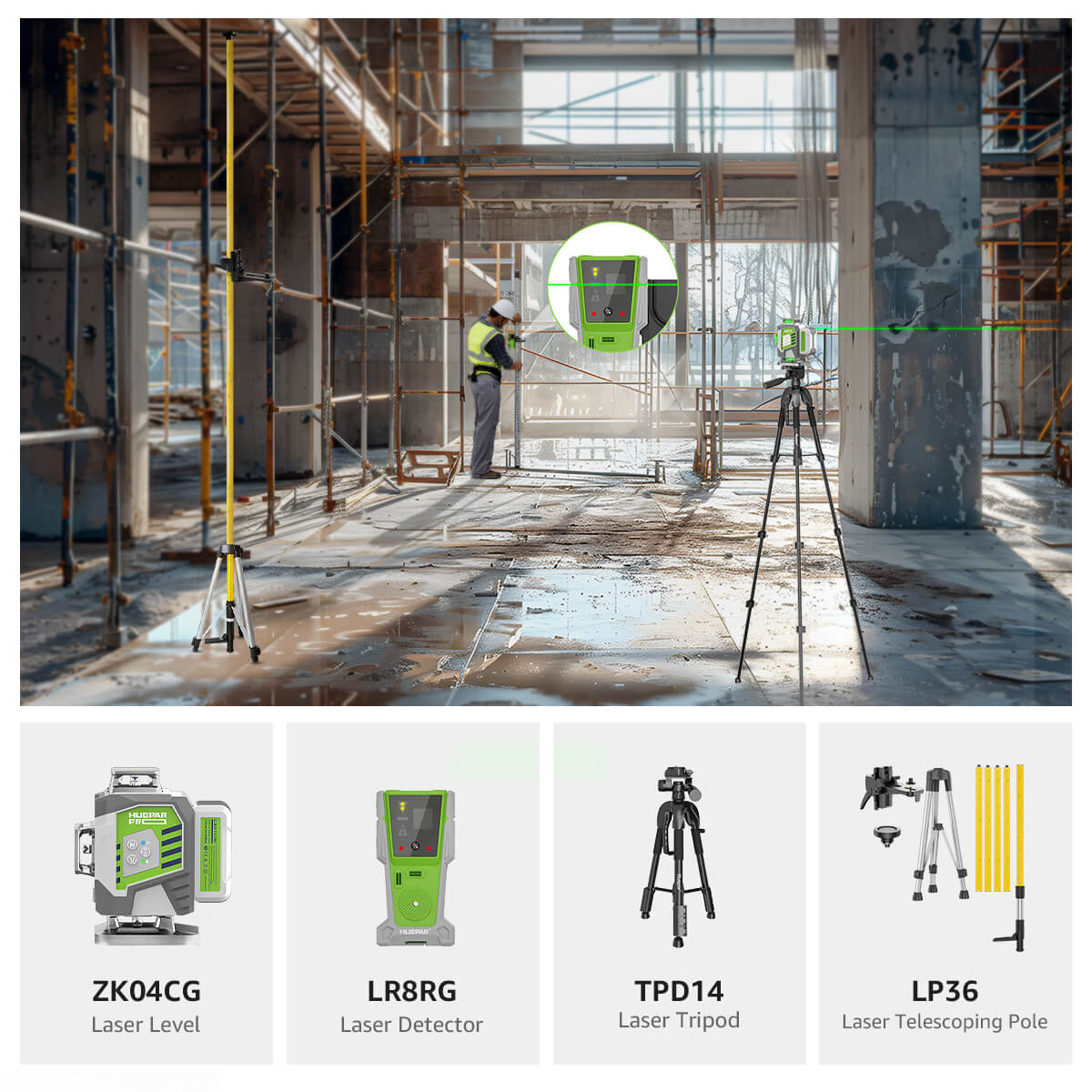

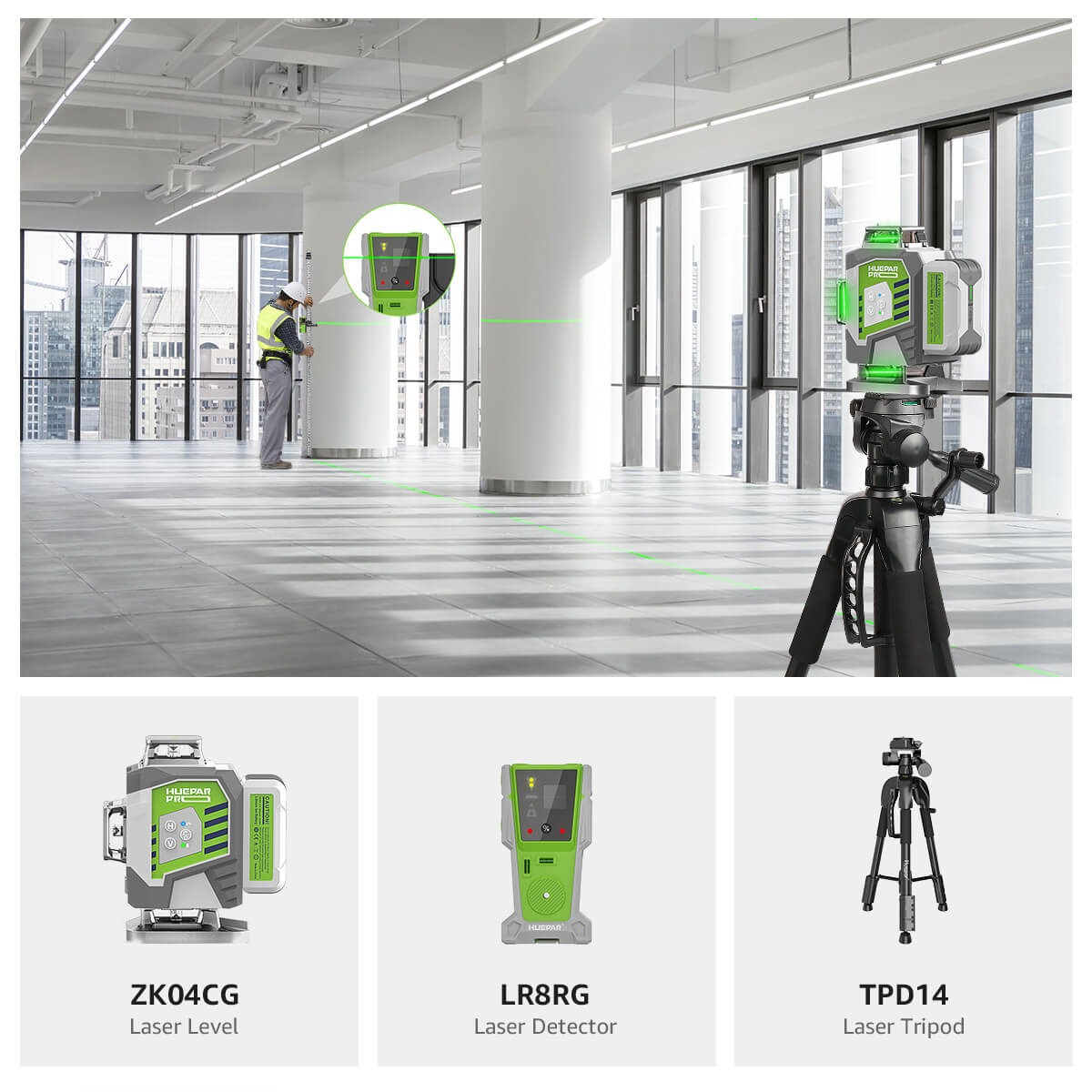

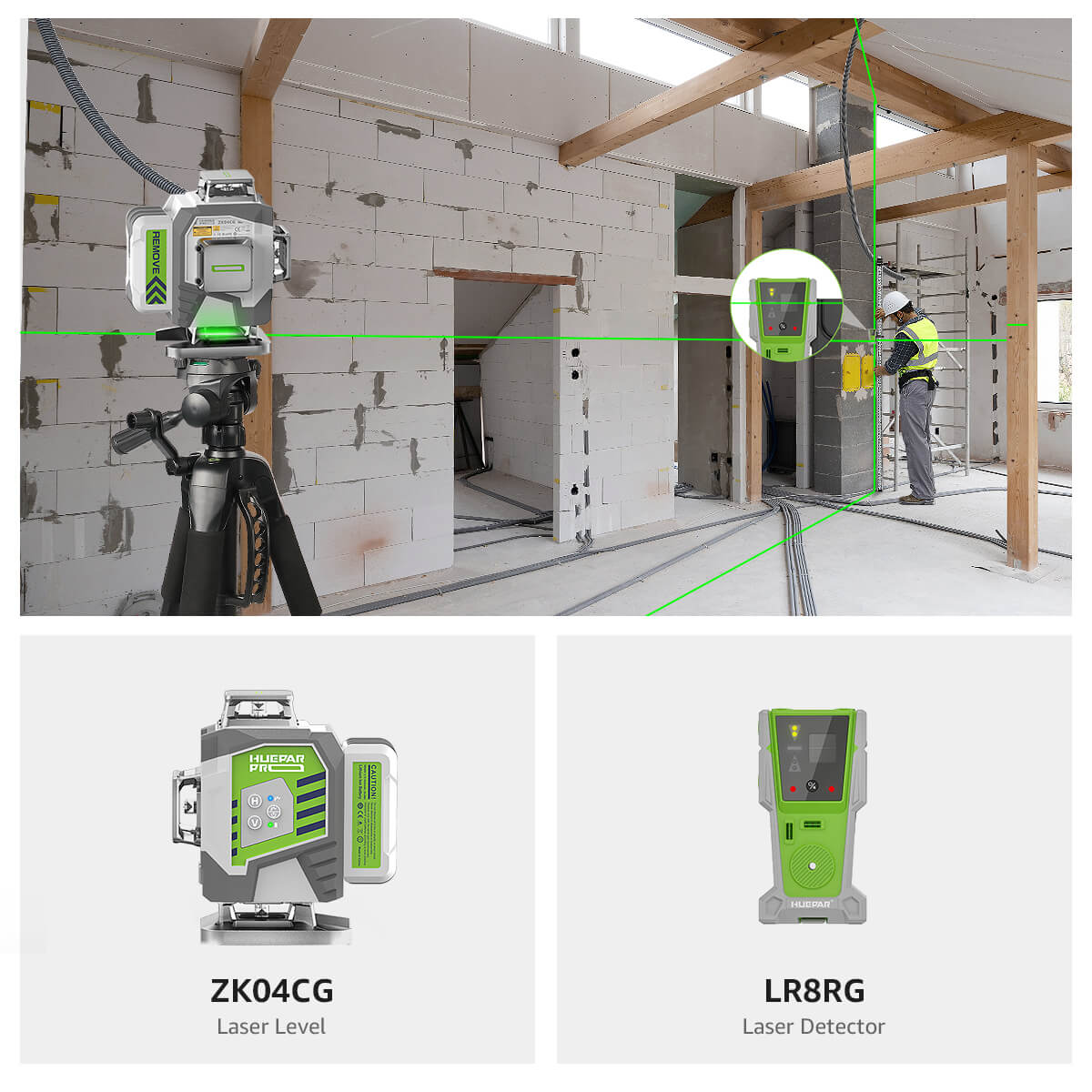

To effectively use a laser level for grading, you'll need a few essential tools:

- Laser level: This is the primary tool that emits a rotating laser beam to establish a level reference line.

- Leveling rod: A tall, graduated rod used in conjunction with the laser detector to measure elevation differences.

- Laser detector: This is a handheld instrument that indicates the position of the laser beam and produces audible or visual signals when on grade with the beam.

- Marking tools: Stakes, spray paint, or other markers to clearly identify the desired grade points on the ground.

- Measuring tape: For measuring distances and ensuring accurate spacing between grade points.

- Safety equipment: Depending on the job site, you may need hard hats, safety glasses, and other protective gear.

Ensure that all the equipment is in good working condition and well calibrated prior to the grading process.

Setting Up the Laser Level

The use of a laser level for grading will entail proper setup on a stable surface. The key steps include:

-

Choose a flat, level surface to place the laser level on. Avoid areas with excessive vibration or movement. A tripod can help provide stability.

-

Power on the laser level and allow it to self-level. Most quality laser levels have an automatic self-leveling function that will correctly calibrate the laser beam.

-

Adjust the height or positioning of the laser level, if needed. You may have to extend the legs of the tripod or reposition the unit so that the laser beam aligns with your intended path.

-

Check that the laser beam is visible and rotating properly. Increase the brightness or switch modes if needed for better visibility.

-

If using the laser level outdoors, be aware of direct sunlight which can make the beam harder to see. Consider operating in shade or early morning/evening hours.

Following these steps will ensure your laser level is properly set up and calibrated to provide accurate, reliable readings for your grading project.

Identifying the Initial Grade Height

-

Determining the starting height is one of the important procedures in grading the area. This first measurement serves as the reference for the grade changes desired.

-

Position the leveling rod at the highest point in the area to be graded. The rod must be firm and vertically straight.

-

Move the laser detector on the leveling rod until it picks up the rotating laser beam. It will beep when it is at the same level as the laser's plane.

-

Once the detector has picked up the laser beam, set it on the rod and lock it in. This sets your initial grade height to start building off of.

Establishing the Desired Grade

After finding the initial grade height, the next step will be setting the desired grade or slope of your project. You will then calculate the wanted fall and shift the laser detector to mark the new height by means of calculation.

To find the desired fall, take into consideration local building codes, drainage requirements, and intended use of the graded area. A typical recommendation is to have a slope between 1-2% away from structures for good drainage. However, the exact slope shall be as instructed per your project.

Once you have calculated what the desired fall is, you will have to move the laser detector along the leveling rod down or up to its new height that corresponds to that slope. For example, for a 1% slope over 100 feet, you would move the detector down 1 foot from the initial height. Mark this position well, since it will give you the reference for establishing the bottom of the grade.

Finding and Marking Bottom of Grade

After establishing the desired grade height, you'll need to navigate to the bottom of the slope to identify and mark that final point. Here are the key steps:

-

Move the laser detector down the slope, keeping it positioned at the desired grade height. Walk slowly and carefully to avoid tripping.

-

Once you reach the bottom of the slope, adjust the detector until the laser beam is perfectly level. This may require some trial and error by raising or lowering the detector.

-

When you've achieved a consistent level reading, this marks the bottom of the desired grade. Double check by sweeping the detector side-to-side to ensure it remains level.

-

Using spray paint, stakes, or another marking method, clearly identify this final point where the grade will terminate. Take measurements from fixed landmarks if needed for future reference.

-

Optionally, you can extend a string line between the starting and ending points to visualize the entire graded slope.

Patience and attention to the laser detector are called for in the correct pinpointing of the bottom to the desired grade. Proper drainage and a smooth transition to the surrounding terrain will be possible with accurate marking.

Tips and Precautions

- Always set up the laser level on a stable, level surface to ensure accurate readings.

- Check the laser level's batteries and calibration before use to prevent errors.

- Use caution when working on slopes or uneven terrain to avoid trips and falls.

- Wear appropriate safety gear, such as hard hats and reflective vests, when working in construction areas.

- Double-check your measurements and calculations to avoid costly mistakes.

- Avoid using the laser level in direct sunlight, as it can interfere with the laser beam's visibility.

- Be aware of your surroundings and watch for obstacles or hazards that could obstruct the laser beam.

- Mark your grade points clearly and consistently to prevent confusion during the grading process.

- Consider using a laser detector or receiver to enhance the laser beam's visibility and extend its range.

- Regularly clean and maintain your laser level and accessories to ensure optimal performance.

Conclusion

A laser level is an effective and accurate way to grade projects, whether you are preparing a site for construction, landscaping, or installing drainage. Just set the laser level up, find your grade height, find the desired grade, and also the bottom of it, and there you are with very correct and even results from your grading. Because the laser level projects a level plane over long distances, it eliminates tiring and time-consuming ways of leveling that could take so much of your time and energy.

Also, the precision in the laser level ensures that the grading is to the specifications required and rules out expensive changes or any other problems throughout the project. Overall, the use of a laser level in grading enables smoothing of the workflow, enhancement of precision, and ultimately the achievement of an effective and professional-grade result.

FAQs

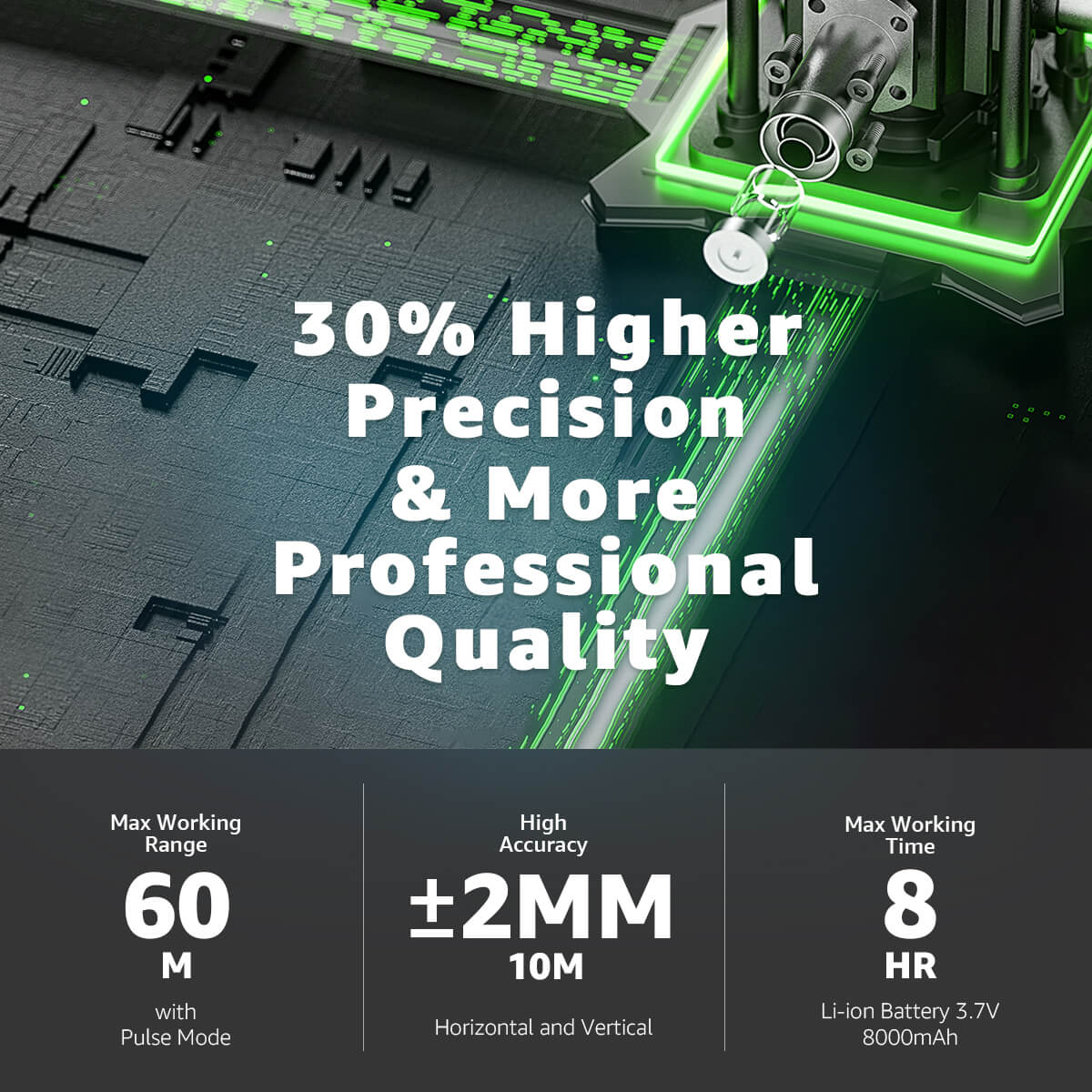

What is the typical accuracy of a laser level for grading?

The absolute majority of laser levels of the class under consideration for the works of grading and leveling have accuracy around 1/4 inch per 100 feet. Higher-end lasers can have better precision, though this level can cope with the majority of grading projects.

How far can a laser level effectively project its beam?

The effective working range of a laser level may be very different for different models and environmental conditions. Most models are capable of projecting a visible beam indoors up to 200-300 feet and outdoors up to 100-200 feet. Working range can be extended with the use of a laser detector.

Are laser levels suitable for use in direct sunlight?

Direct sunlight can make the laser beam difficult to see, reducing its effective range. Look for laser levels with higher output power or use a laser detector to improve visibility in bright conditions.

How do I ensure accurate readings when using a laser level on sloped ground?

When working on sloping grounds, the laser level should be set up on firm and level ground. The unit should be mounted on a tripod or level base to prevent shifting during the operation process since it may result in inaccurate readings.

Can a laser level be used for both outdoor and indoor projects?

Yes, most laser levels can be used for outdoor grading and indoor leveling tasks, such as laying floors or installing cabinets. However, using them outdoors may be limited by environmental factors such as sunlight and wind.