Unlocking Precision: All You Need to Know about 3D Laser Levels

What Are 3D Laser Levels and How Do They Work?

The Basics of 3D Laser Level Technology

3d laser levels use laser beams to show points and lines in three dimensions. They create a visible network that carpenters, electricians, and builders can use for accurate alignment. A 3D level sends out laser lines along the X, Y, and Z axes. This allows users to measure and align in all directions without moving the tool. The device uses either a pendulum or gyroscopic system to stay level, even on uneven surfaces. Its internal mechanisms ensure the laser's precision. Many models come with a self-leveling feature that activates once the device is within a certain range of being level. Some also have a lock to protect the leveling mechanism during transport.

Understanding the Differences: 3D vs 2D Laser Levels

3D and 2D laser levels are both useful tools, but they serve different needs. A 2D laser level projects lines on a single plane, either horizontally or vertically. This is great for tasks like hanging pictures or installing chair rails. In contrast, 3d laser levels emit laser lines on three planes: up, down and across. This means you can map a room's layout on all walls, ceilings and floors at once. These levels make complex jobs, like installing cabinets or tiling floors, much easier. The key difference is that 3D levels give a full-room layout, making them ideal for more detailed work.

Key Components and Operations of 3D Laser Levels

3d laser levels are advanced tools that feature several key components for their operation. These include a laser diode, which emits the laser light; a level base that can be fixed or adjustable for ensuring a stable setup; an optical system to shape and direct the laser beam; and a sensor for detecting the laser's position. They also come with a power source, like batteries or an AC adapter. To operate, the level is set up on a stable base. The laser diode then projects a 360-degree light plane across horizontal and vertical axes. Some models can produce multiple lines, creating a '3D' effect in the workspace. This allows users to map out an entire area with precise measurements, ensuring everything is level and aligned. The sensor detects the lines' position for accuracy. Simple calibration might be needed before use. With these components working together, a 3D laser level can perform a variety of leveling and layout tasks with high precision.

Benefits of Using 3D Laser Levels in Construction and DIY Projects

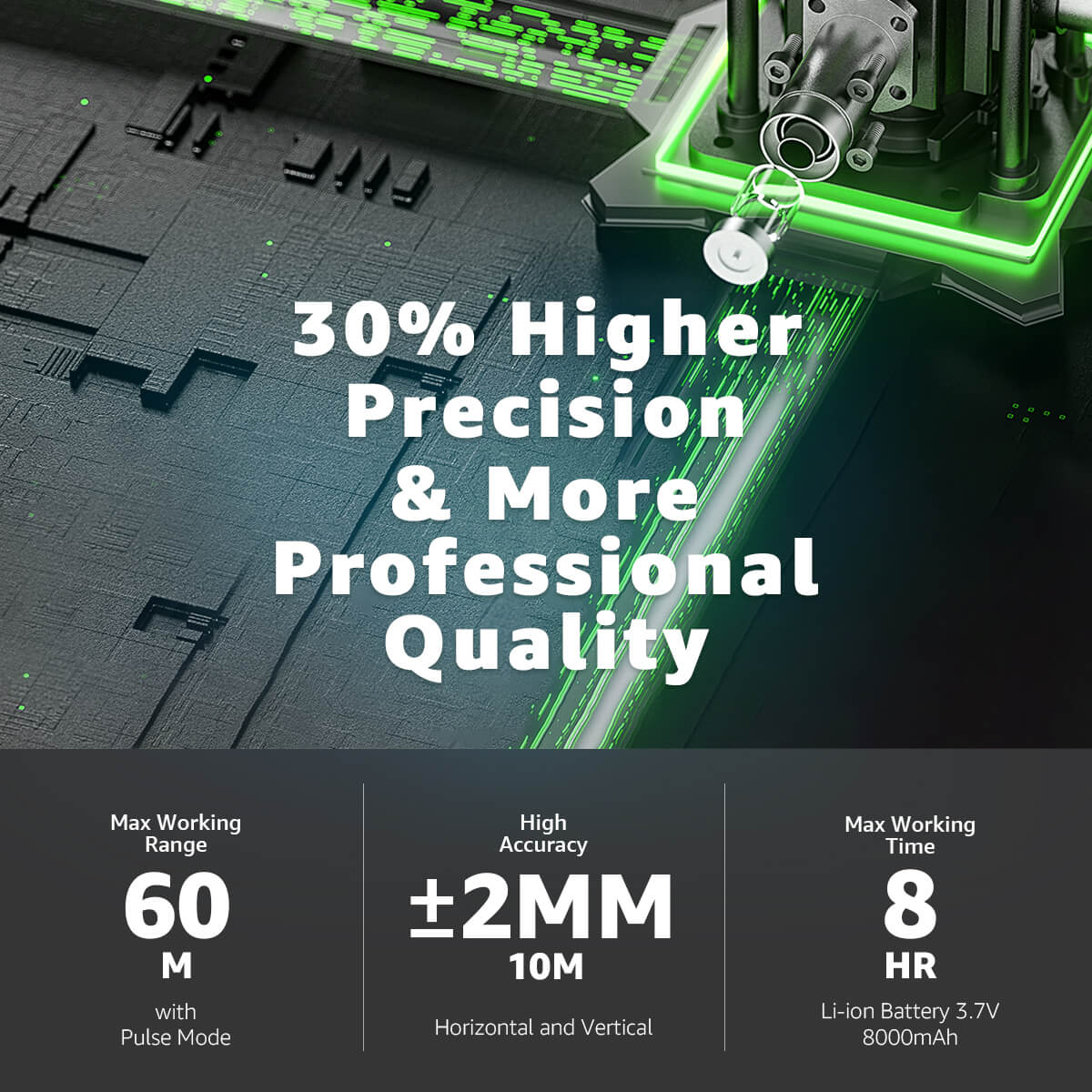

Accuracy and Precision in Measurements

3d laser levels have transformed the construction and DIY landscapes with their remarkable precision. Using these tools ensures that measurements are spot-on, eliminating the guesswork and frequent rechecks associated with traditional levels. Their sophisticated technology projects accurate three-dimensional planes of light, enabling precise alignments and layouts for tasks such as cabinetry, tiling, or framing. This high level of accuracy is beneficial in delivering quality results and adhering to exacting standards, thus preventing costly errors and material waste. By utilizing a 3D laser level, professionals and hobbyists alike can achieve a level of precision that manual methods cannot match.

Time-Saving and Efficiency Improvement

3d laser levels are a game-changer in time management on a job site. They work fast and cut down on the usual time taken for setup and measuring. By casting precise lines on all axes, workers can move quickly and avoid errors. This means you finish tasks faster and can take on more projects. With a 3D laser level, there's no need for constant checking. It does its job while you do yours, blending accuracy with speed effectively.

Versatility Across Various Applications

3d laser levels are not just for constructing large buildings. They are also handy in many smaller tasks. They can be used to align cabinets, tiles, and more in homes. For DIY lovers, they are great for creating perfect wall hangings. Their use in laying out landscaping designs is also a plus. Overall, these tools are very flexible. They work for many different projects, making them great for pros and amateurs alike.

Choosing the Right Laser Level for Your Needs

4D Laser Levels: The Next Dimension in Laser Measuring Tools

The world of laser levels is quickly advancing with the introduction of 4D laser levels. These tools, which represent the next step in precision measuring, offer an additional plane of projection. It's this fourth dimension – the ability to provide a 360-degree horizontal and vertical plane – that sets them apart. With such comprehensive coverage, 4D lasers make aligning, leveling, and mapping a space simpler than ever. Whether you're working on complex architectural projects or need precise alignments in carpentry, a 4D laser level can be a game-changer. Its complete level and plumb capabilities ensure accuracy from floor to ceiling and wall to wall, making it a powerful tool in any craftsman's arsenal.

Considering Cross Line Laser Level Options

When looking at the options for a laser level, cross line laser levels should definitely be on your list. This type is perfect for jobs requiring precise horizontal and vertical lines. Cross line lasers project bright crossing horizontal and vertical lines. They are ideal for tasks like tiling, hanging cabinets, or even wallpapering. Here's what to look for:

- Beam Visibility: Pick a unit with a beam you can see clearly, even in bright light.

- Self-Leveling: Look for a model with self-leveling capabilities for the utmost accuracy.

- Mounting Options: Consider how the laser can be mounted or if it's tripod compatible.

- Durability: Make sure the laser level is robust enough for your work environment.

- Battery Life: Check how long the battery lasts and what type of batteries it uses.

Keep these points in mind, and you'll find a cross line laser level that meets your project's demands.

Factors to Consider When Selecting a Laser Level

When picking the right laser level, consider these key factors:

- Accuracy: Look for levels with high precision for reliable results.

- Range: Make sure the device can cover the area you need.

- Durability: Choose a level that can withstand your work environment.

- Battery life: Longer battery life means less downtime.

- Ease of use: User-friendly interfaces can save you time and hassle.

- Price: Find a balance between quality and what you can afford.

These points will guide you to select a laser level that meets your needs.