Unlocking Precision: The Ultimate Guide to 3D Laser Levels

What Are 3D Laser Levels?

Understanding the Basics of 3D Laser Technology

3d laser levels are tools that emit beams on all axes. X, Y, and Z axes give a full space outline. They use lasers to map points in 3D space. This helps in building and design work. The lasers form a 3D grid on a work area. They make sure that things like walls and pipes are right on the spot. 3D stands for three dimensions: up/down, left/right, and forward/back. These levels are very precise for complex tasks. They are also easy to use for all skill levels.

The Evolution of Laser Levels: From 1D to 3D

Laser levels have made huge strides over time. We started with 1D, which gave us a single line. Then came 2D, allowing lines across two planes. Now, 3d laser levels are here. They project lines along three planes. This means more precision in one go. With 3D tech, you can do layout work faster. Also, you can check level and plumb easier. 3D lasers are great for complex projects. They bring a new level of detail to work sites.

Key Features of 3D Laser Levels

3d laser levels are advanced tools for precise alignment. They offer key features:

- 360-degree Projection: This allows users to create a full room layout with one setup.

- Multiple Laser Lines: They can project several lines at once. This aids in complex tasks.

- Self-Leveling: Most 3D lasers self-level within a certain range. This ensures accuracy.

- Outdoor Visibility: With stronger beams, they work well even in bright conditions.

- Mounting Options: They come with various mounts for different job needs.

These features make 3d laser levels a top pick for pro users.

How Do 3D Laser Levels Work?

The Mechanics of 3D Laser Level Operation

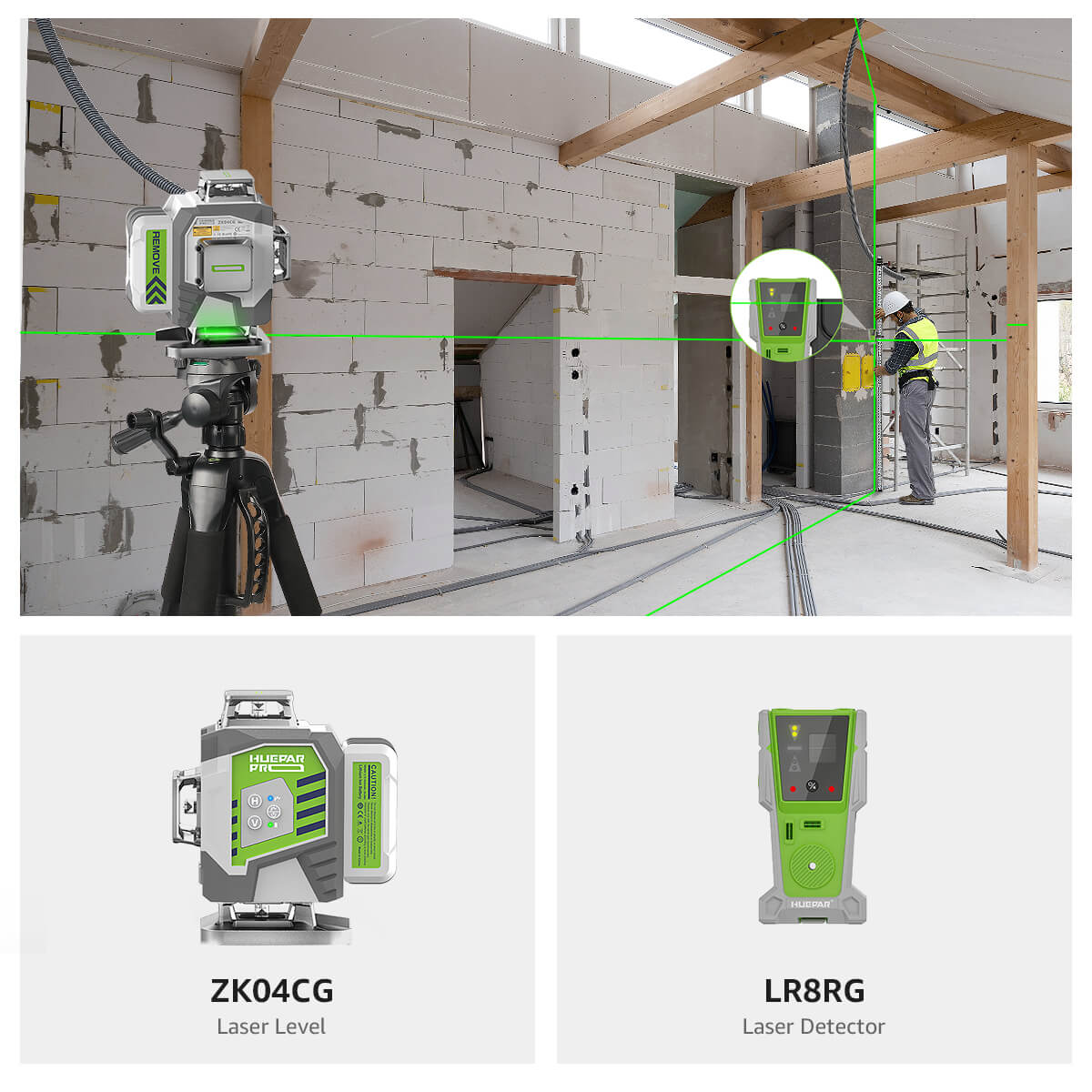

3d laser levels beam light to mark a three-dimensional grid. This grid guides builders and engineers. They can align walls, pipes, and wires with it. Inside the level, mirrors and diodes create the lasers. These lasers rotate to make lines. They form vertical, horizontal, and cross lines. These lines help with accurate levels. People can see the lines with glasses or a detector. Some levels also beep for precision. They work well indoors and outdoors. They need a firm base to be most accurate.

Setting up a 3D Laser Level for Optimum Accuracy

To set up a 3D laser level for best accuracy, follow these steps:

- Select a Stable Surface: Place your laser level on a flat, stable surface to avoid movement.

- Self-Leveling Check: Ensure the laser level's self-leveling feature is active for precision.

- Adjust the Tripod: If using a tripod, adjust it until the level's bubble is centered.

- Target Alignment: Position the laser targets where you need clear, visible lines.

- Test Accuracy: Use measuring tools to confirm the laser is accurate.

- Lock the Pendulum: If your model has a pendulum lock, engage it to secure the laser mechanism.

- Calibrate If Necessary: Periodically recalibrate your laser level as needed for consistent accuracy.

These steps help achieve precise results in measuring and aligning tasks.

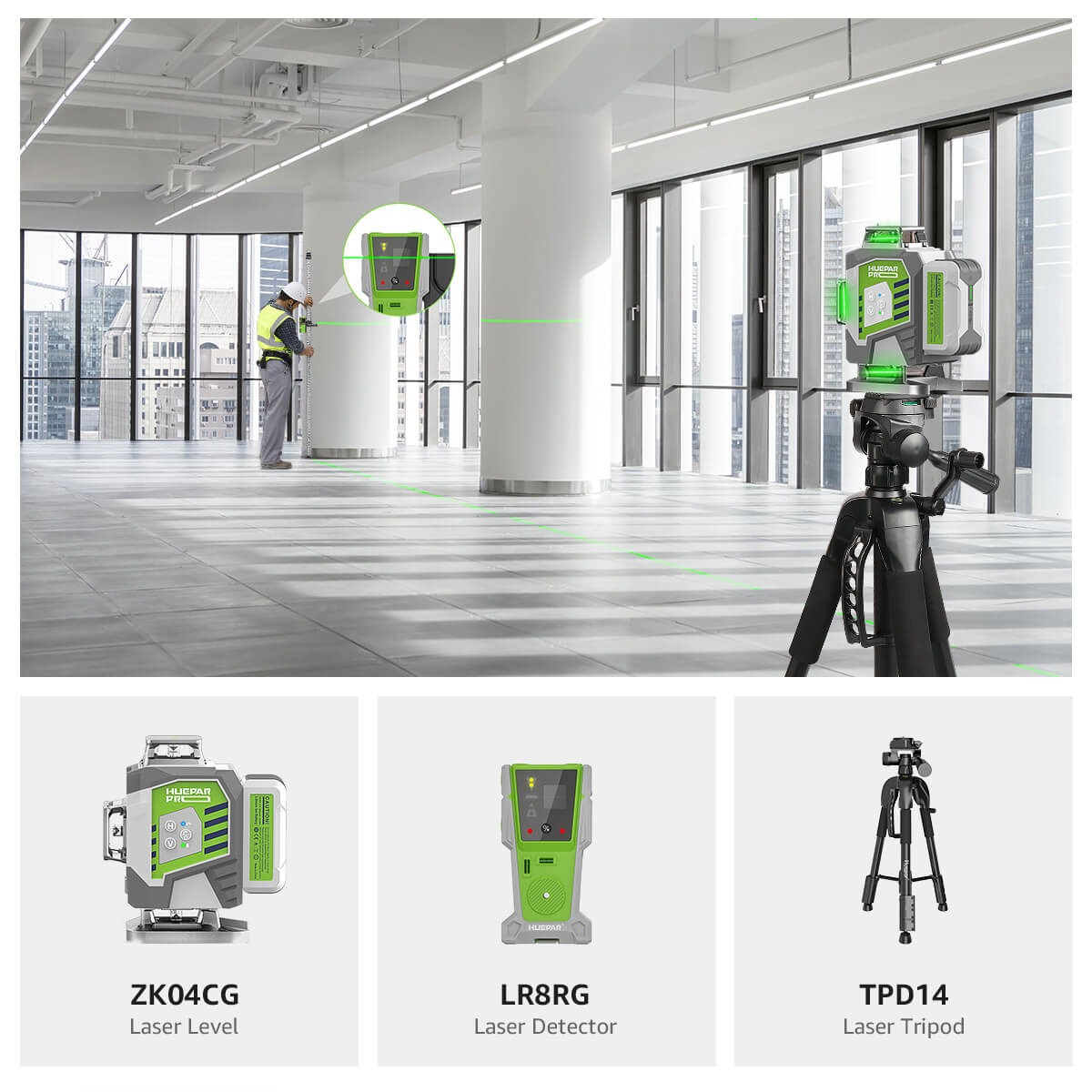

Common Applications of 3D Laser Levels in Construction

3d laser levels have transformed how construction tasks are approached, simplifying complex alignments and ensuring precision on the jobsite. Utilized across various stages of construction, they are indispensable for tasks like aligning walls, installing plumbing, and setting out floor tiles. These tools are equally important for electricians and carpenters who require accurate leveling for fixtures and fittings. Large-scale operations such as laying foundations or aligning structural components also benefit from the exactitude that 3D laser levels offer. From home renovations to major construction projects, 3D laser levels are vital for accurate measurements and alignments.

Choosing the Right 3D Laser Level

Cross Line vs. 3D Laser Levels: What's the Difference?

Choosing the right laser level is key in many projects. Two options stand out: cross line and 3d laser levels. While both serve to guide precision, they differ. Cross line lasers project intersecting horizontal and vertical lines. They are great for tasks like hanging pictures or installing cabinets. On the other hand, 3D laser levels emit lines that cover 360 degrees. They create a full room layout, which is perfect for complex projects. So, for simple tasks, a cross line may suffice. But for full room coverage and intricate layouts, a 3D laser level is the go-to tool.

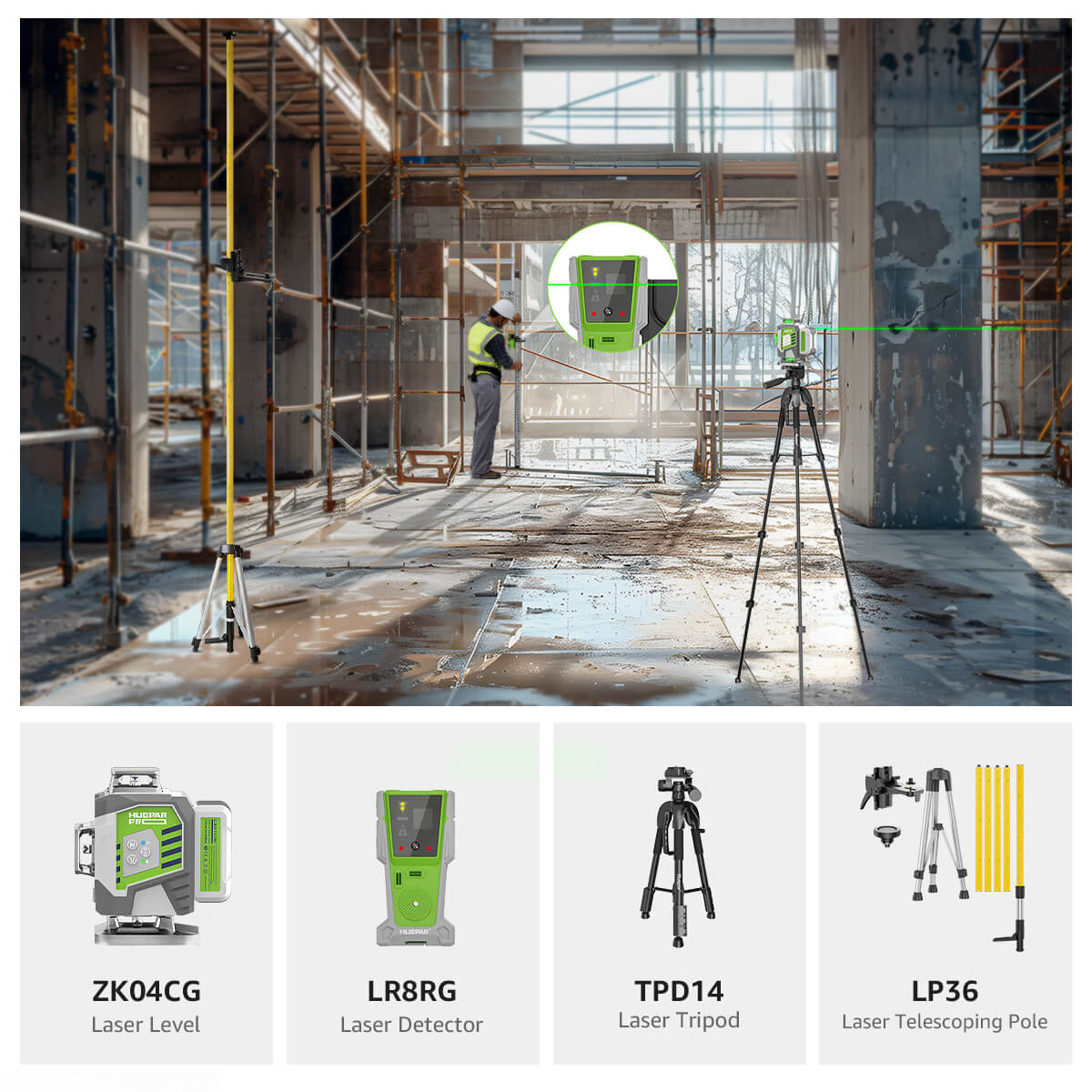

Factors to Consider When Purchasing a 3D Laser Level

When picking a 3D laser level, weigh these key points:

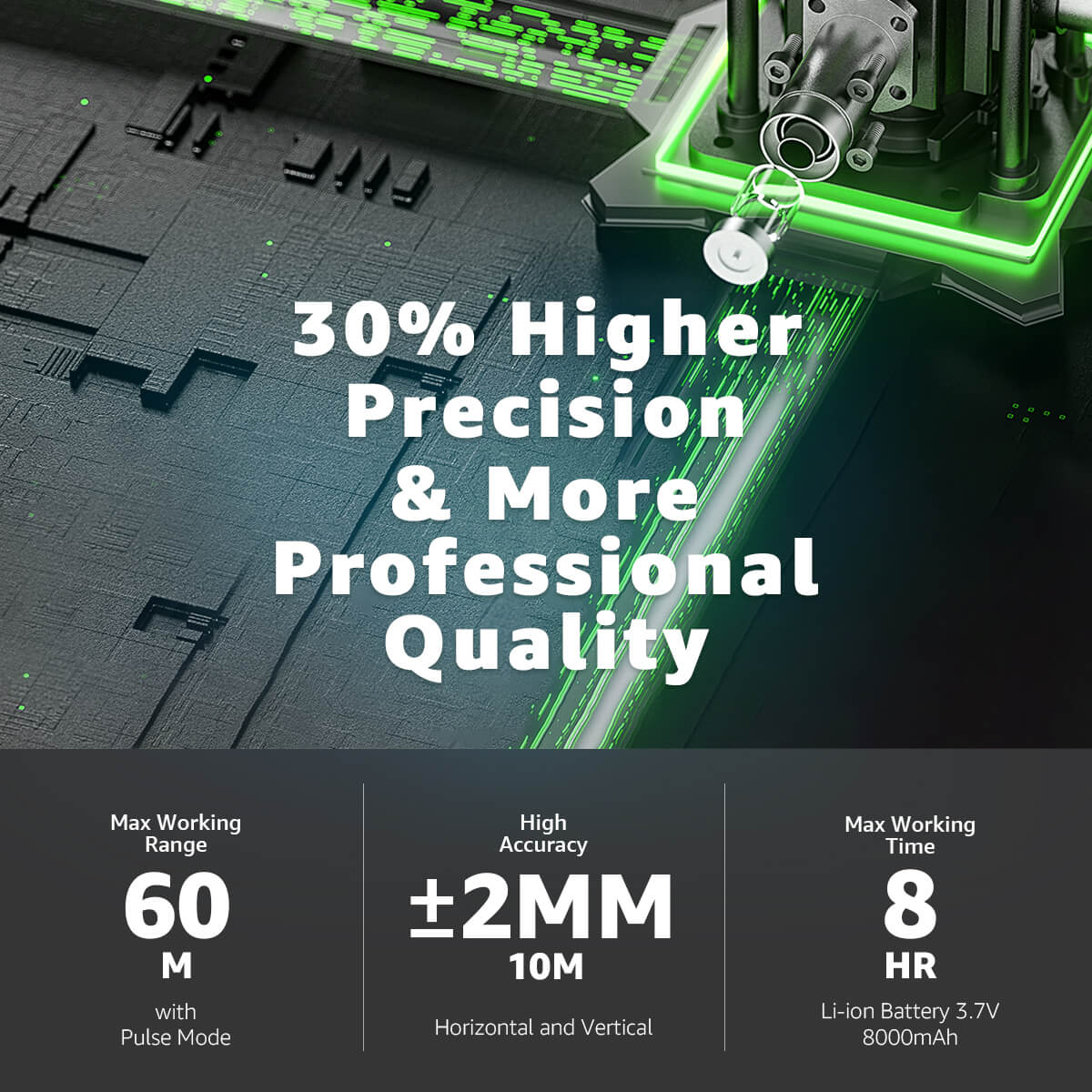

- Accuracy: Look for high precision levels; fractions of a degree matter.

- Durability: It should endure rough sites and resist water and dust.

- Battery Life: Opt for long-lasting power to avoid work interruptions.

- Visibility Range: Check if it works well for your space size, indoors and outdoors.

- Self-Leveling Feature: Saves time, ensuring level lines automatically.

- Mounting Options: It should mount easily on various surfaces or stands.

- Price: Balance cost and quality, considering how often you'll use it.

These factors lead to a wise choice, fitting your specific construction needs.

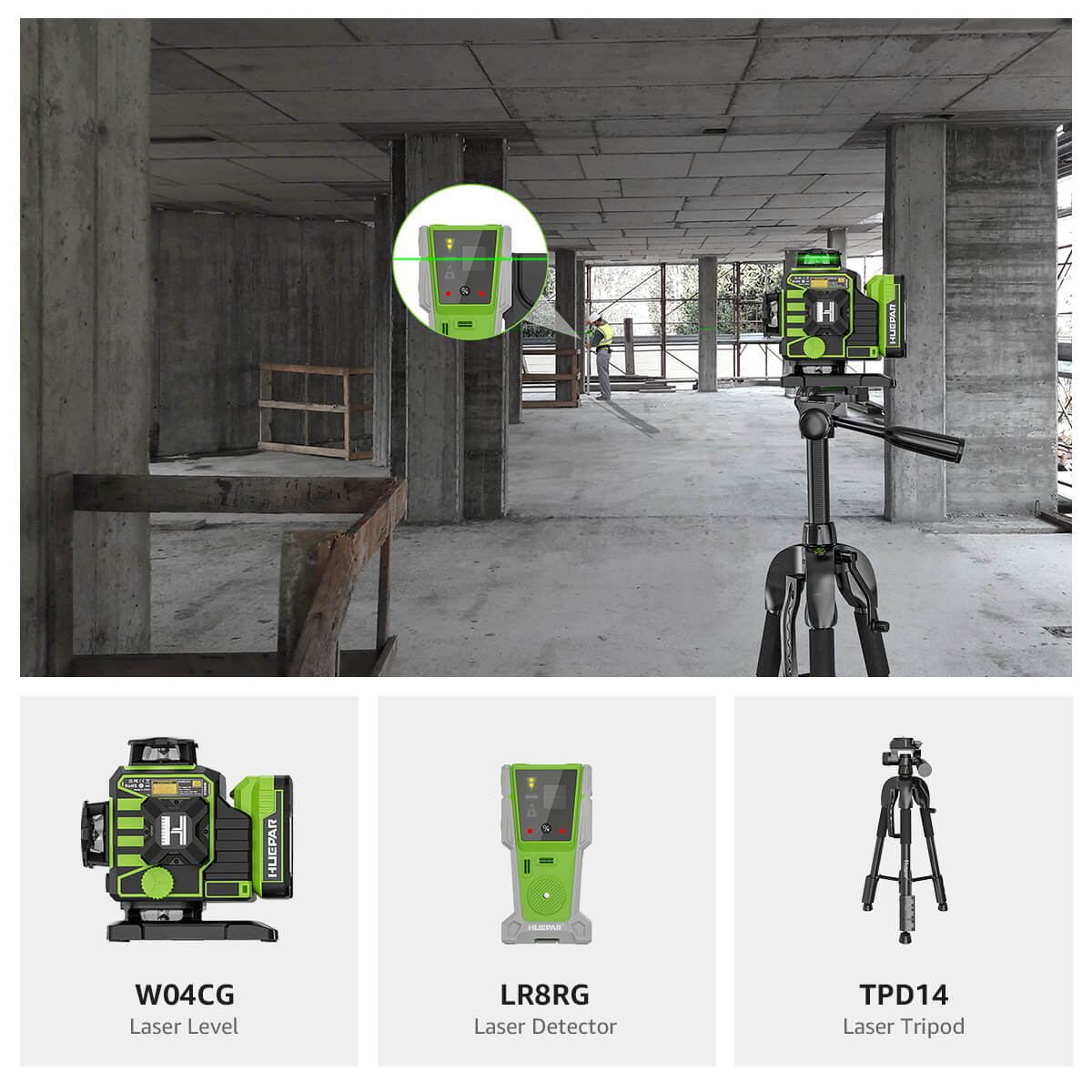

Top Picks for 3D Laser Levels on the Market

- DeWalt DW089LG: This model offers green laser technology for better visibility and longer working range.

- Bosch GLL3-330CG: Known for its Bluetooth connectivity and 12V battery system for extended use.

- Huepar 603CG: Provides full 360-degree layout with a triple power supply, including a rechargeable lithium battery.

- Makita SK104Z: Combining affordability with reliability, it's equipped with a self-leveling capability and dual line modes.

- Spectra Precision LT58G: It shines for its ultra-bright green laser lines and wide horizontal angle coverage.

When choosing one, compare their features, price points, and customer reviews to find the best match for your needs.