The Ultimate Guide to 3D Laser Levels: Enhancing Precision in Construction

Introduction to 3D Laser Levels

What Are 3D Laser Levels?

3d laser levels are advanced measuring tools. They create 360-degree visible laser lines around a room. This helps builders to align and level items without moving the tool. Just set up the level once. It can do horizontal and vertical measurements at the same time. Easy to use and saves time on complex jobs. Perfect for tasks that need a high level of precision.

How Do 3D Laser Levels Work?

3d laser levels use cutting-edge tech to ensure accuracy. Here's how they work. First, they emit laser beams in three planes. These planes form an 'X', 'Y', and 'Z' grid. This allows you to check and align points in 3D space. The device's self-leveling feature uses gravity to stay accurate. A pendulum inside swings to find the true level. Then, the lasers lock in this position. Some models use electronic sensors too. These signals adjust the laser to ensure straight lines. You get precise, visible lines on surfaces at various angles. This lets workers align structures easily. It reduces mistakes and speeds up the job. Now you know the workings of 3D Laser Levels.

The Benefits of Using 3D Laser Levels in Construction

Using 3d laser levels in construction offers several advantages.

First, they enhance accuracy. These devices provide precise reference lines. As a result, errors reduce and final builds improve.

Second, they save time. By projecting lines on all planes, they eliminate the need for manual marking. This means projects can move faster.

Third, they are versatile. These lasers work well indoors and outdoors. They suit all construction stages.

Lastly, they improve safety. Workers do not need to climb to mark lines. This reduces fall risks. These benefits make 3d laser levels a smart choice for builders.

Comparing Different Types of Laser Levels

Cross Line Laser Levels: An Overview

Cross line laser levels are a common tool in construction. They project bright, straight lines onto surfaces. These lines can be horizontal, vertical, or both at the same time. They help ensure features like tiles, pipes, or beams are straight and well-aligned. These levels are simple to use and ideal for indoor tasks like hanging pictures or installing cabinets. They are less complex than 3d laser levels and often more affordable. Cross line lasers are best for simpler, smaller-scale projects.

4D Laser Levels: The Next Dimension in Leveling

4D laser levels are the newest tech in leveling devices. They project a 360-degree line on all four walls, plus the ceiling and floor. This makes them perfect for complex projects. Techs use them to ensure total level accuracy. They are great for tasks that need precise vertical and horizontal alignment. 4D lasers save time and improve work quality. They are often used in big construction as well as fit-outs and refurbishments.

3D vs 4D vs Cross Line Laser Levels: Which One Do You Need?

Choosing the best laser level depends on your project needs. Cross Line Laser Levels are great for basic tasks. They project lines on flat surfaces. These are good for hanging pictures or tiling walls. 3D Laser Levels offer more features. They can project lines on all three axes. This makes them perfect for complex layouts. Use them for cabinetry or installing drop ceilings. 4D Laser Levels are the most advanced. They give an extra level of precision with 360-degree coverage. This is ideal for tasks that need the utmost accuracy.

Pick the one that fits your job:

- For simple DIY, go with a cross line laser level.

- For detailed indoor work, choose a 3D laser level.

- For full room coverage and high precision, a 4D laser level is best.

Practical Applications and Best Practices

Standard Applications of 3D Laser Levels in Construction

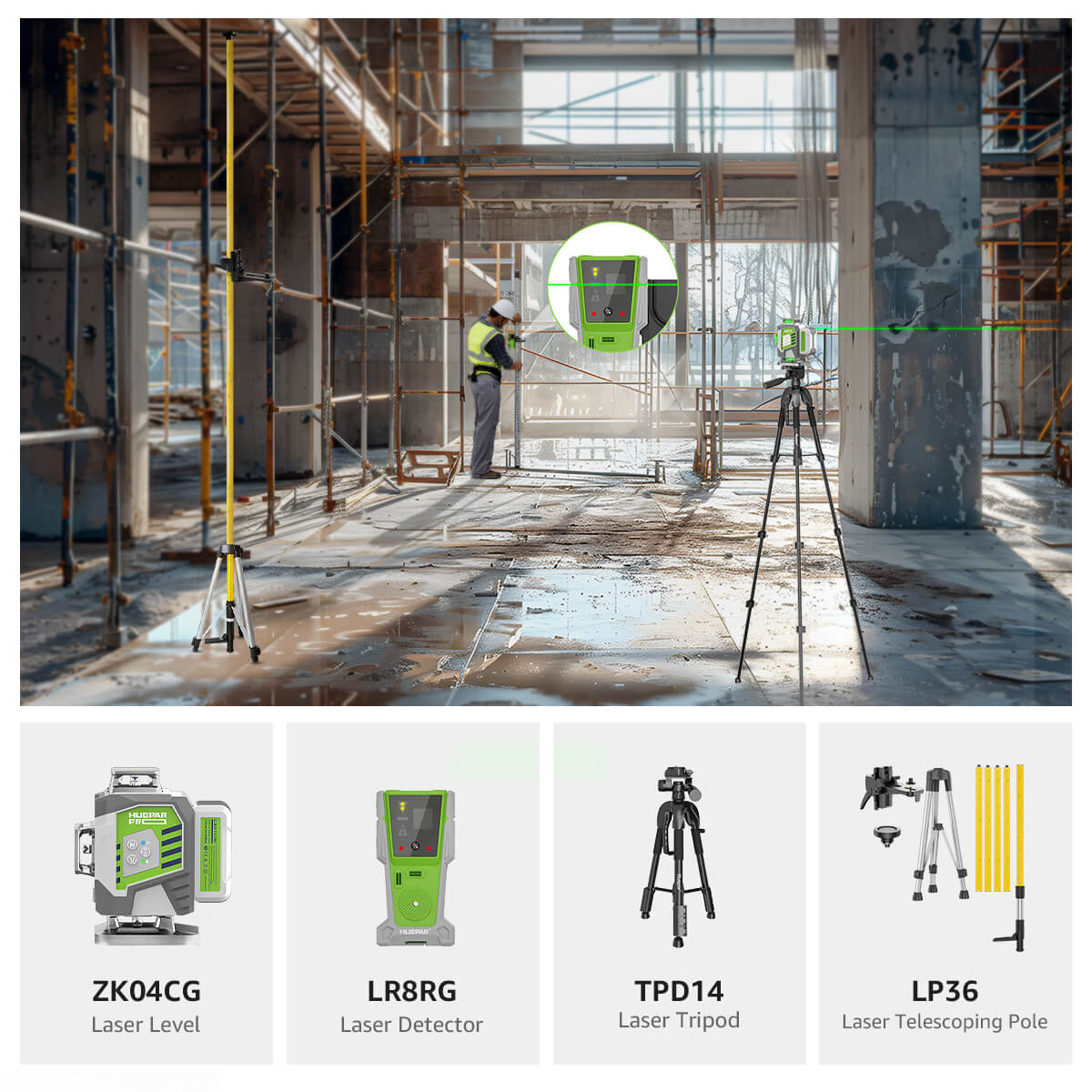

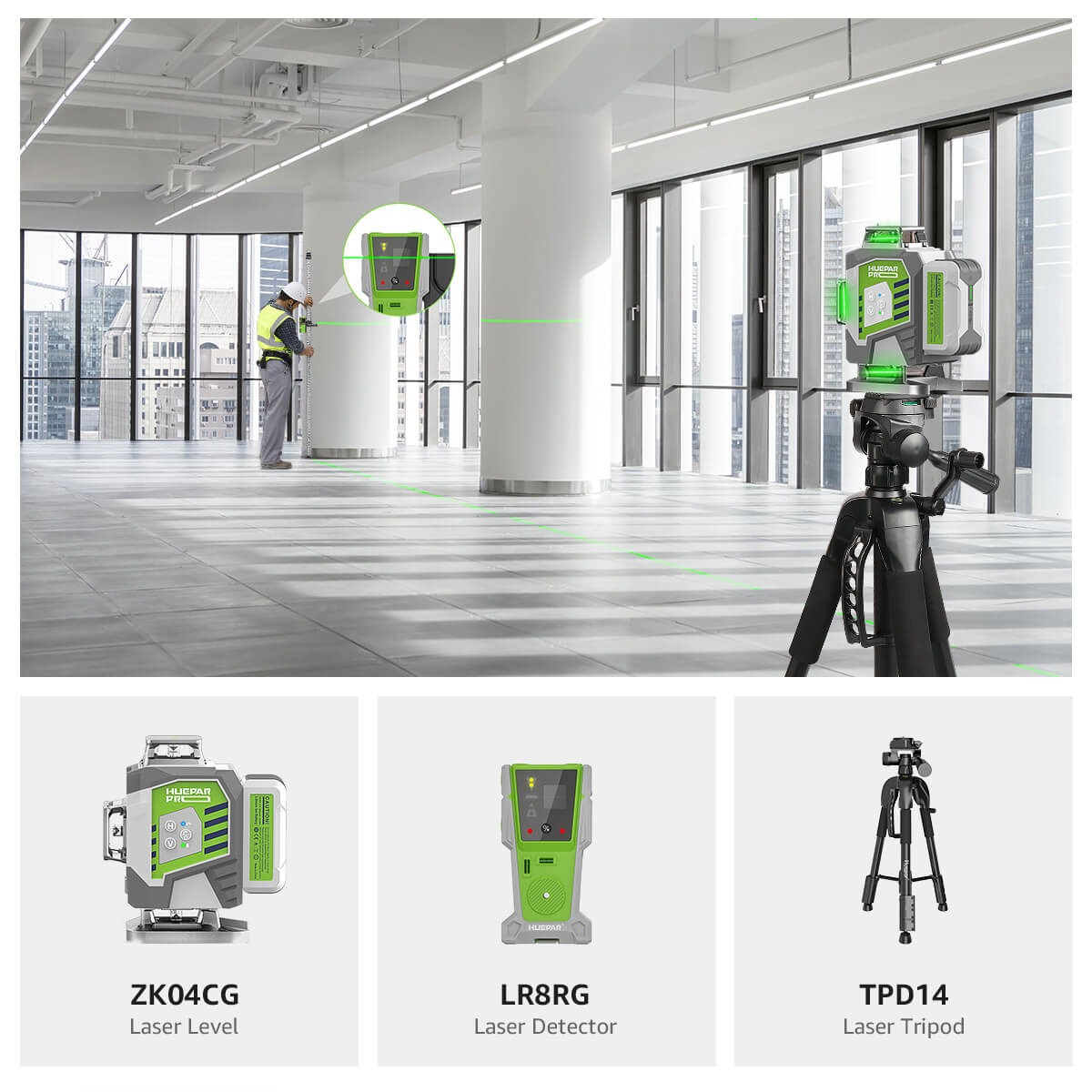

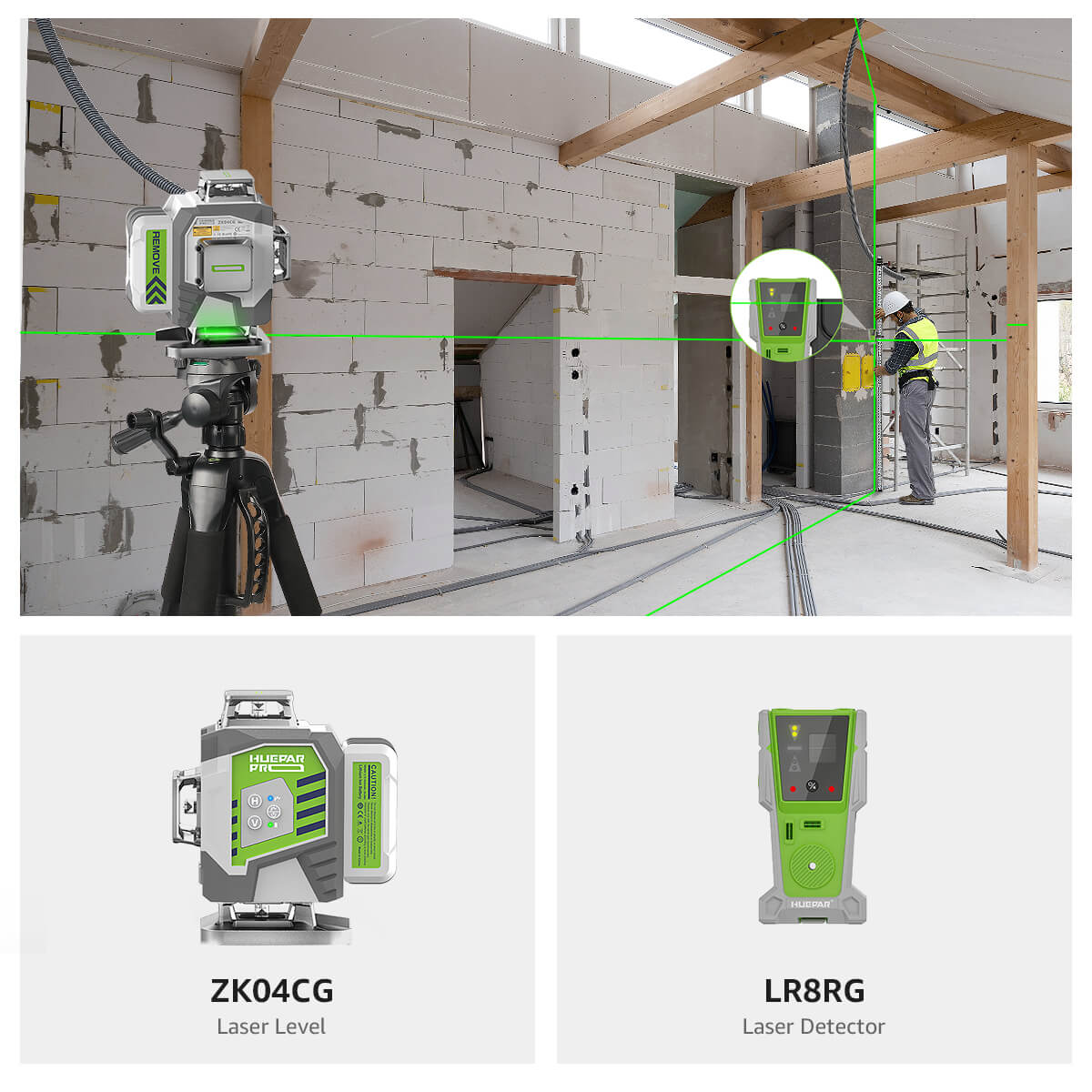

3d laser levels are widely used in construction to ensure accuracy and efficiency. They help in various tasks such as:

- Aligning and plumbing walls: Ensures walls are perfectly vertical.

- Leveling floors: Guarantees floors are flat and even.

- Installing drop ceilings: Helps maintain a consistent height across the ceiling.

- Setting up drainage systems: Aids in creating the correct incline for water flow.

- Aligning fences and decks: Keeps lines straight and structures level.

Using these devices can save time and reduce errors in these common construction tasks.

Advanced Techniques: Tips for Maximizing Precision

To maximize precision with 3d laser levels, consider these tips:

- Regularly calibrate your laser level for accurate results.

- Ensure the laser level is positioned on a stable surface to avoid movement.

- Use the laser level in a low-light environment to enhance the visibility of the laser.

- Keep the laser level and its sensors clean to maintain its accuracy.

- When working outdoors, choose a laser level with a strong signal that won't be easily disrupted.

Employing these techniques will lead to more accurate and reliable measurements in your construction projects.

Choosing the Right 3D Laser Level for Your Project

Selecting the ideal 3D laser level for your construction project is crucial. Here are some tips:

- Consider the Environment: Indoor projects may need different features compared to outdoor ones, where sunlight can interfere with laser visibility.

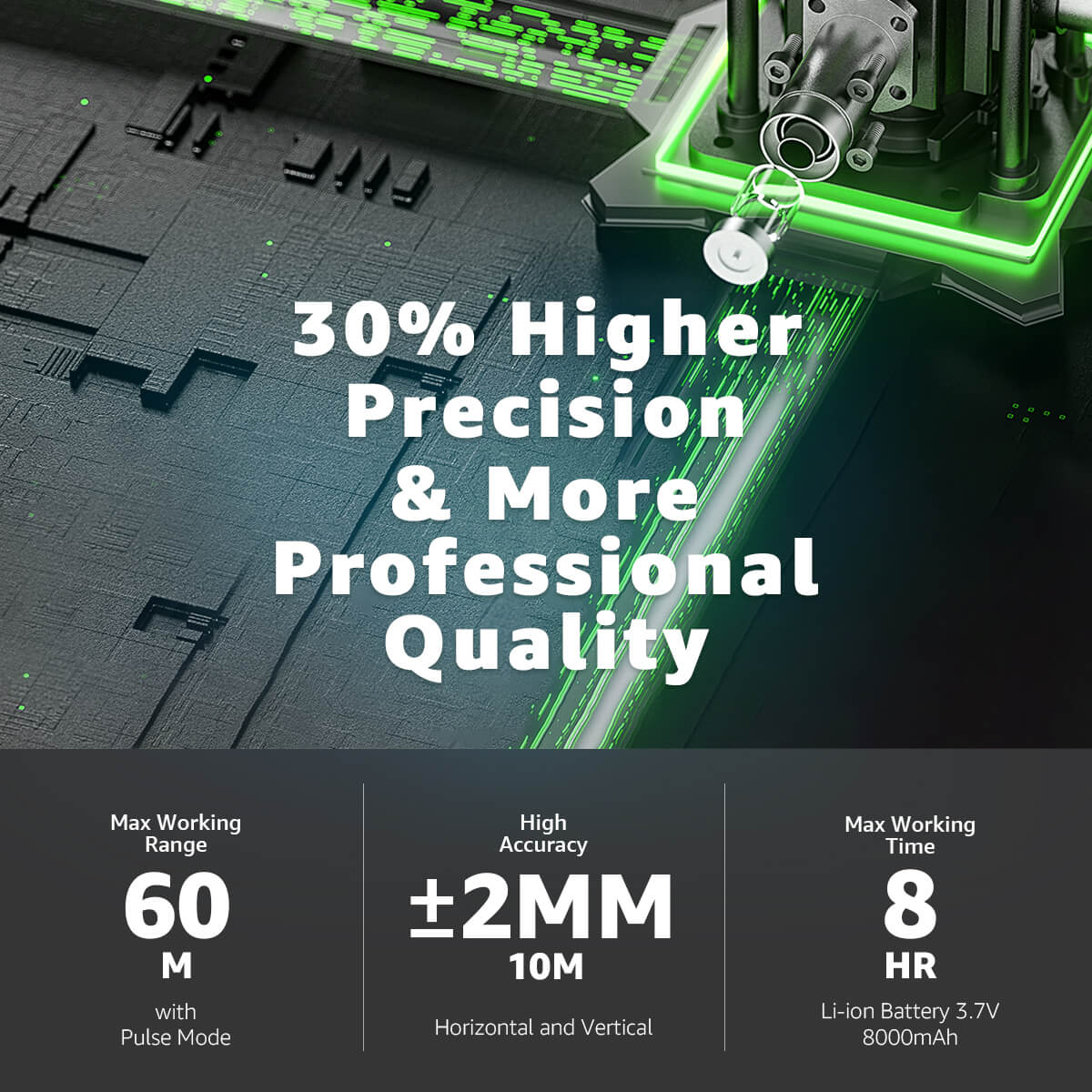

- Assess the Level’s Range: The size of your project site determines the required range. Ensure the level's scope matches your needs.

- Check for Durability: Construction sites can be harsh. Look for robust levels that withstand bumps and falls.

- Evaluate Accuracy: Precision is key in construction. Opt for levels with high accuracy ratings.

- Verify Battery Life: Longer battery life means less downtime. Choose levels with sufficient power endurance.

By focusing on these aspects, you can find a 3D laser level tailored to your project’s unique demands.