Unlocking Precision: A Deep Dive into 3D Laser Levels for Accurate Measurements

Introduction to Laser Levels

The Evolution of Laser Technology in Construction

The journey of laser technology in the construction industry is akin to a revolution. Starting with rudimentary leveling tools, the field has witnessed a dramatic transformation. Initially, builders used water tubes or manual methods to ensure level lines. Later, the first laser levels offered basic functionality, projecting single red lines. Technological advancements have since given rise to sophisticated 3d laser levels. These modern tools can project multiple lines at once, covering all angles, and offering unparalleled precision. They have changed how construction tasks are approached, boosting accuracy and efficiency across projects.

Types of Laser Levels and Their Uses

- Dot Laser Levels: Ideal for transferring points from floors to ceilings.

- Line Laser Levels: Best for leveling tasks across walls or horizontally.

- Rotary Laser Levels: Suited for outdoor use and large area leveling.

- Combination Laser Levels: Combine lines and dots for complex jobs.

- 3D Laser Levels: Allow for accurate measurements in three planes.

Each type of laser level caters to specific tasks in construction and DIY projects. Dot lasers are simple and used mostly for aligning items at a single point. Line lasers are perfect for installing cabinets, tiling, or framing pictures. Rotary lasers cover larger distances, which is ideal for outdoor landscaping or laying foundations. Combination lasers provide the versatility of both line and dot level functions. Lastly, 3d laser levels offer comprehensive solutions for detailed projects requiring full room layout with X, Y, and Z axis control.

3D Laser Levels Explained

Understanding the Technology Behind 3D Laser Levels

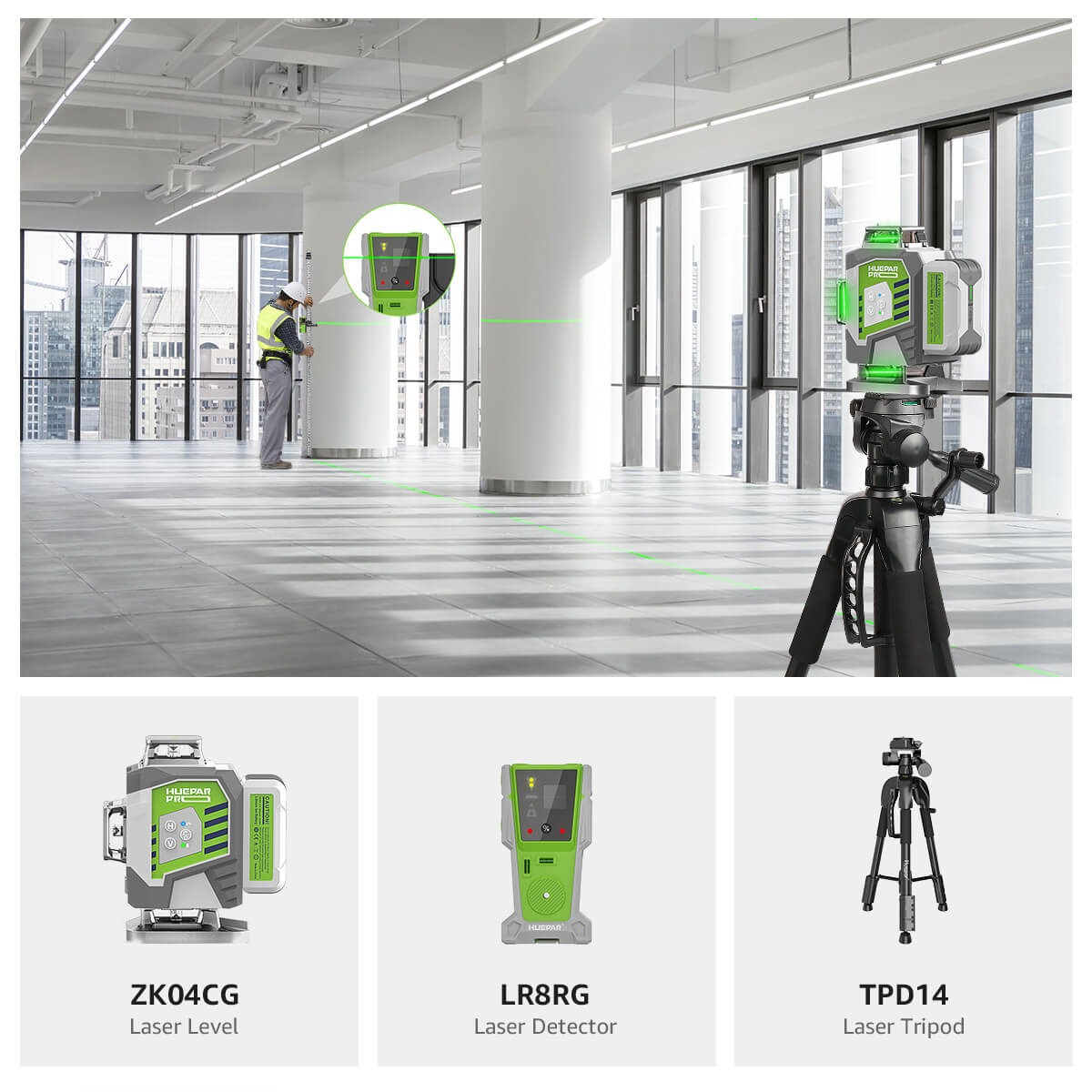

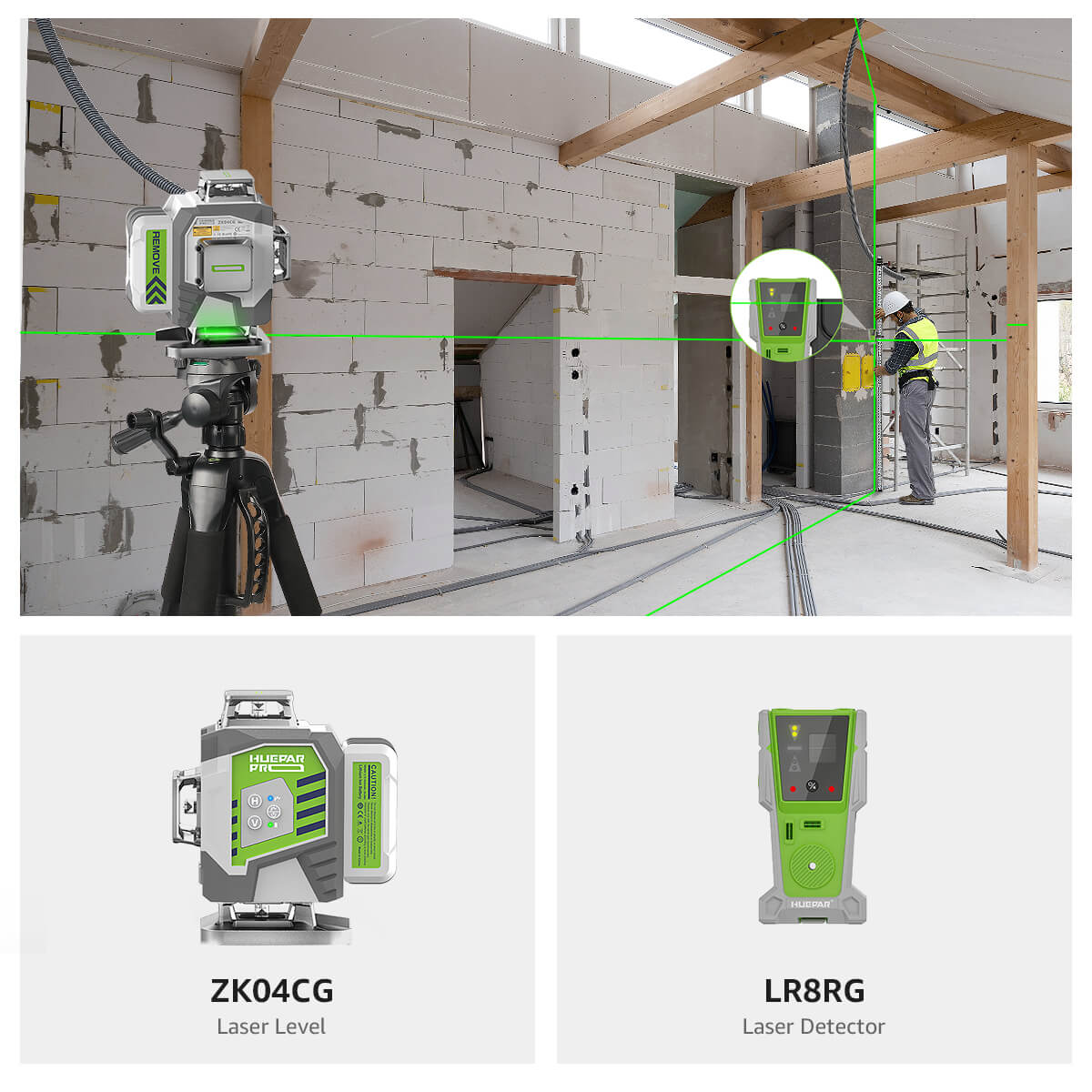

3d laser levels use cutting-edge technology to ensure high precision in measuring and alignment. This tool projects laser lines in three dimensions. Unlike traditional levels, it allows you to simultaneously map horizontal and vertical planes. This is ideal for tasks that require exactness from all angles. Inside these devices, complex components like diodes and optical lenses work together. They create crisp, bright lines that can be seen even in well-lit conditions. Some models connect with apps for additional control. The use of 3D lasers marks a leap in the tools for builders, engineers, and DIY enthusiasts alike.

Applications of 3D Laser Levels in Various Industries

3d laser levels are versatile tools used across various industries. In construction, they help set accurate layout lines for both interiors and exteriors. For architects and engineers, precise alignment makes 3D models and structural plans come to life with ease. In manufacturing, they assist in setting up complex machinery, ensuring precision in assembly lines. Even in film production, 3D laser levels aid in creating detailed sets and special effects. The benefits include saving time, improving accuracy, and reducing errors in all these fields.

Key Features and Benefits of Using 3D Laser Levels

3d laser levels boast superior accuracy, projecting lines in three dimensions. This precision ensures tasks like installing cabinets or laying tiles are done right the first time. They save time with quick setup and use one tool for multiple layout tasks. Their bright lasers enhance visibility under various lighting conditions. Plus, many models come with self-leveling features, making them user-friendly. Enhanced durability is also a key aspect, as they are often designed to withstand tough job site conditions.

Choosing the Right Laser Level

Cross Line vs. 3D Laser Levels: Which Is Better for Your Project?

When deciding between a Cross Line and a 3D Laser Level, your project's needs are key. Cross Line Lasers cast intersecting horizontal and vertical lines onto a surface. This helps with tasks like hanging pictures or tiling walls. They are simple to use and good for indoor jobs. But for more complex projects, a 3D Laser Level is ideal. It projects lines in 360 degrees, allowing full room layout with one setup. This level is great for precise tasks in construction and landscaping. To choose, think about your job’s complexity and the precision needed.

Top Considerations When Selecting a 3D Laser Level

When choosing a 3D Laser Level, consider these key points:

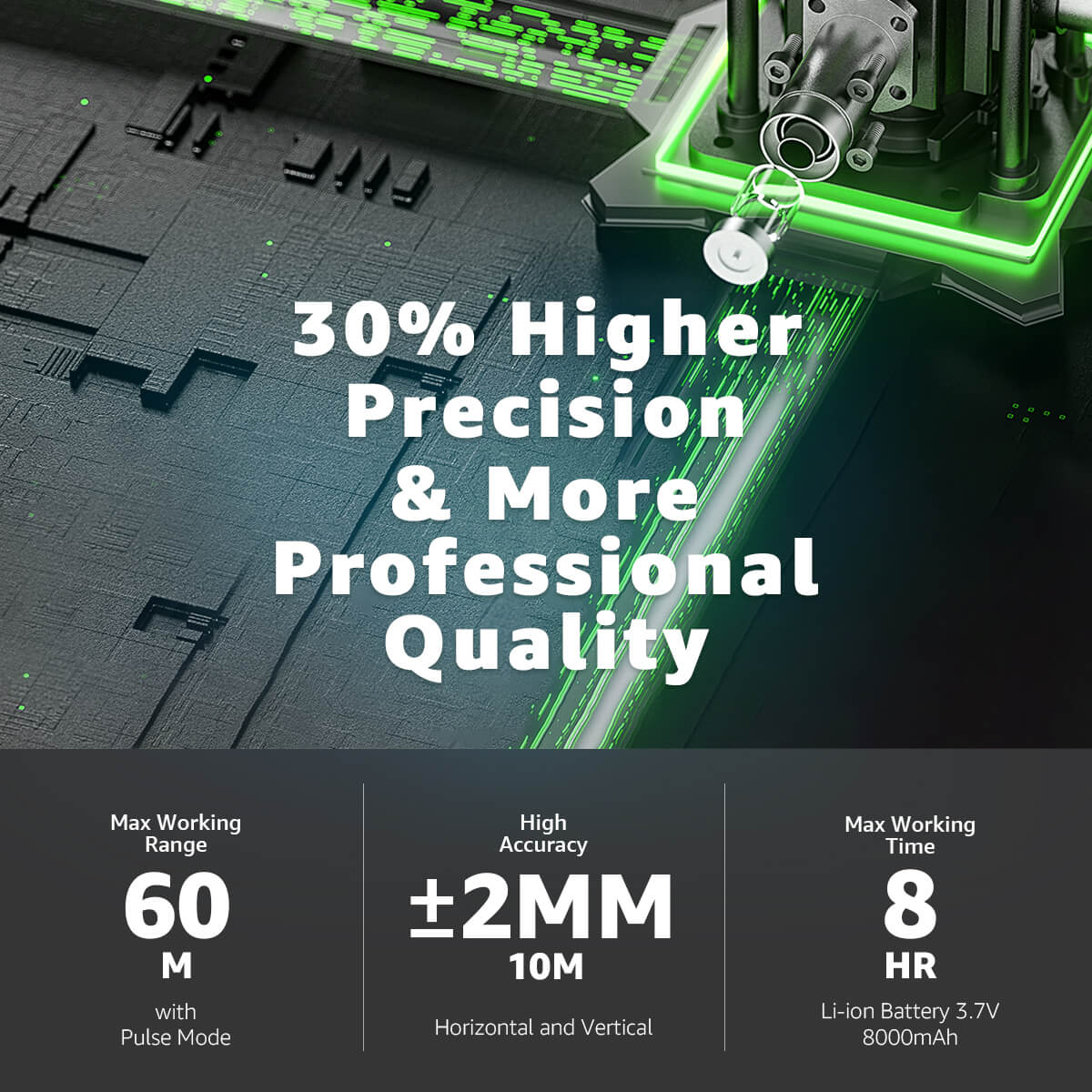

- Accuracy and Range: Look for a model with high accuracy and a working range that suits your needs.

- Self-Leveling Capability: A self-leveling feature is vital for accurate and effortless setup.

- Battery Life: Ensure the device has a long battery life to avoid frequent recharging or replacements.

- Durability: Opt for a robust design that can withstand the rigors of the job site.

- Ease of Use: A user-friendly interface and clear displays make operation simpler.

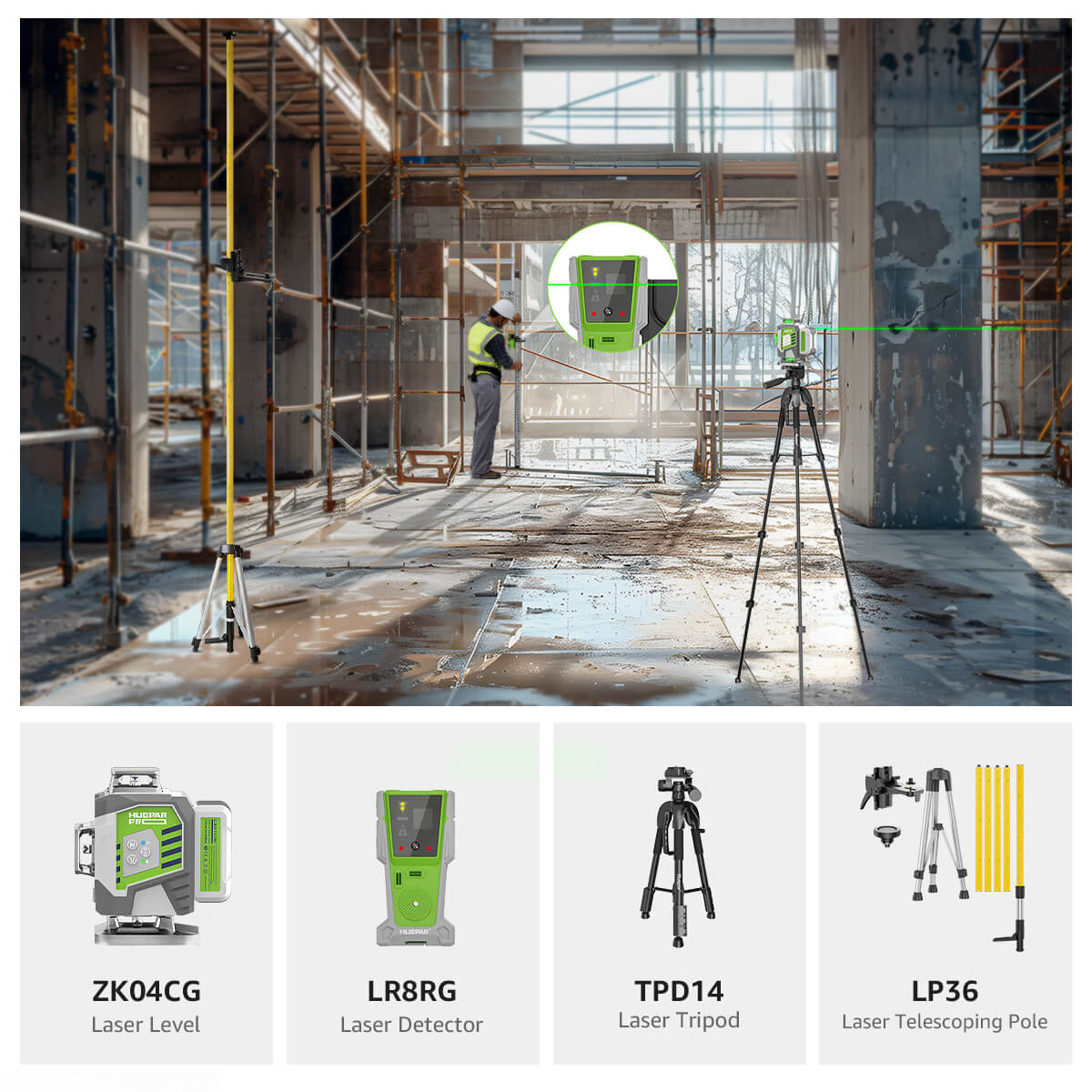

- Mounting Options: Check for versatile mounting solutions to work in different scenarios.

- Price: Consider the cost and whether it fits your budget while meeting your requirements.

- Warranty and Support: Seek out a product with a solid warranty and reliable customer support.

The Future of Laser Levels: Advancements and Predictions

Looking ahead, the laser level technology is poised for significant advancements. Predictions for the future of laser levels include improved accuracy and range, integration with digital platforms for data analysis, and enhanced battery life for extended use on work sites. Moreover, the incorporation of AI for autonomous leveling and the development of hybrid systems combining 3D, cross-line, and 4D laser levels hint at an exciting era for construction and surveying professionals.