Unlocking Precision: A Guide to 3D Laser Levels in Modern Construction

Understanding Laser Levels: Basic Concepts and Types

Introduction to Laser Levels

Laser levels have changed how we build. They use beams to make sure our work is straight. These tools can show lines on walls, floors, or objects. They help builders and DIY fans to work with high precision. These levels come in different types like cross line and 4D. With lasers, you can work faster and make fewer mistakes. They are a key part of modern construction. In the next topics, we will see how these tools work and why they are so helpful.

Different Types of Laser Levels: From Cross Line to 4D

Laser levels come in various forms, each with unique features. The most common type is the Cross Line Laser Level. It projects straight lines along the X and Y axes. This type is great for basic tasks like hanging frames. Next, we have the 3d laser levels. They project lines along three axes. So, they are perfect for complex layouts and alignments in construction. There's also the advanced 4D Laser Levels. These tools add a new level of precision with 360-degree coverage. They can project lines on all walls, floors, and ceilings at once. With 4D levels, setting up a fully leveled space is faster and easier.

How Laser Levels Work in Construction

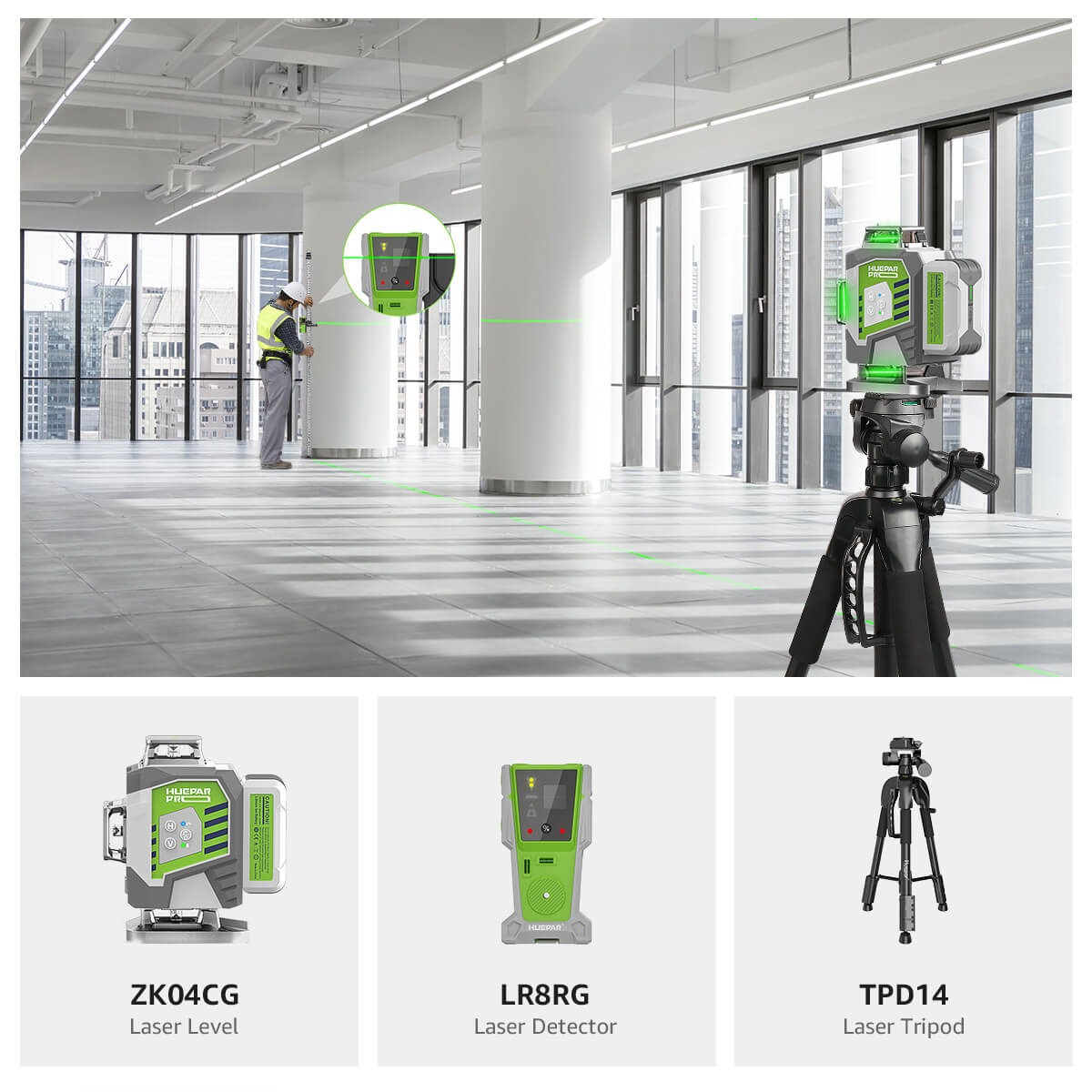

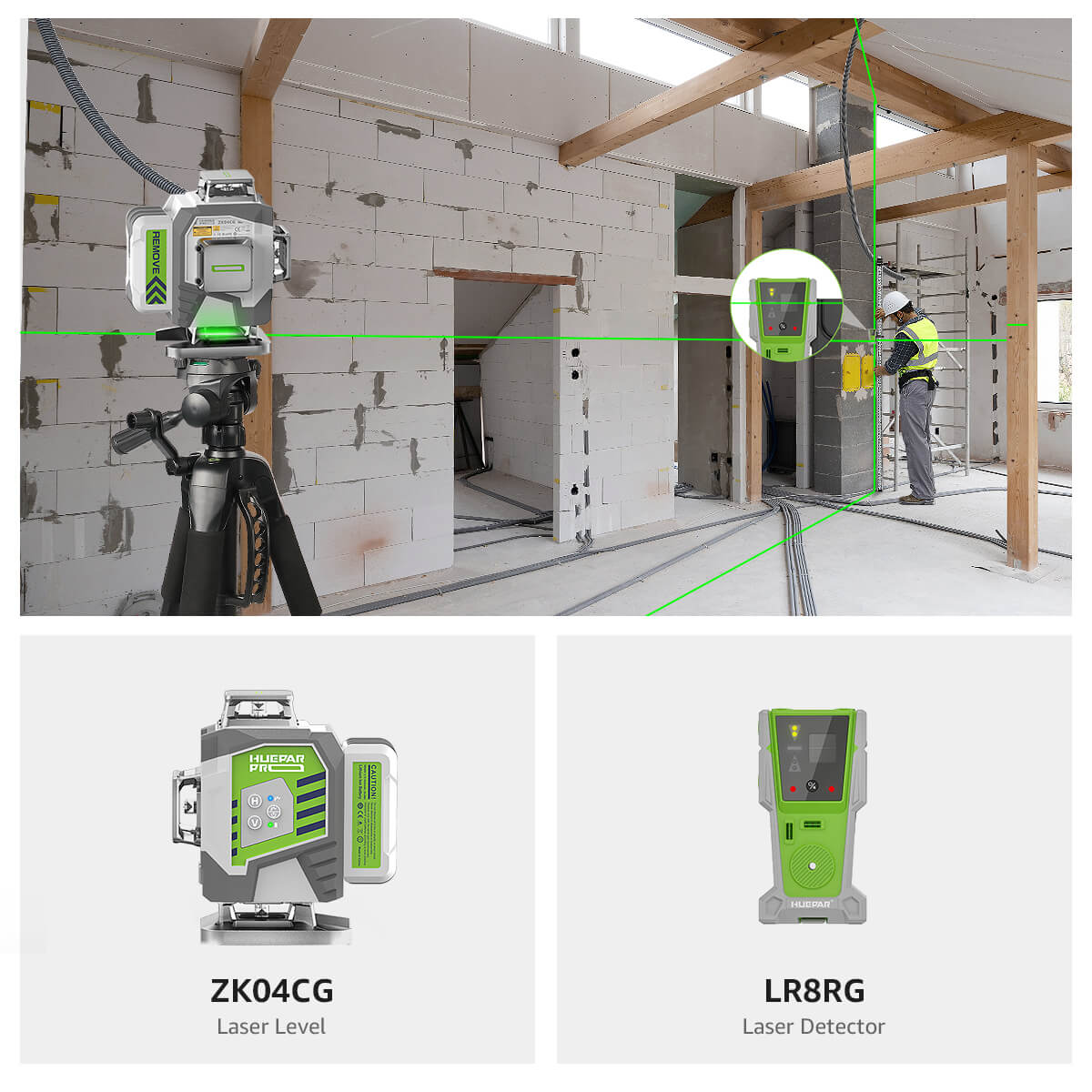

Laser levels are vital in construction for creating precise lines and measurements. They project a light, either a dot or a line, that workers use as a guide. This ensures walls, tiles, and other elements are straight and level. As tools, they range from simple cross-line laser levels to advanced 4D models. Each type has its own work method. The 3d laser levels can make lines on all sides. They help to map out a full room layout at once. On bigger sites, 4D laser levels offer more detail. They allow workers to set up more complex plans. With lasers, tasks like framing and installing systems get more accurate and quicker.

Advantages of Using 3D Laser Levels in Construction

Increased Accuracy on Construction Sites

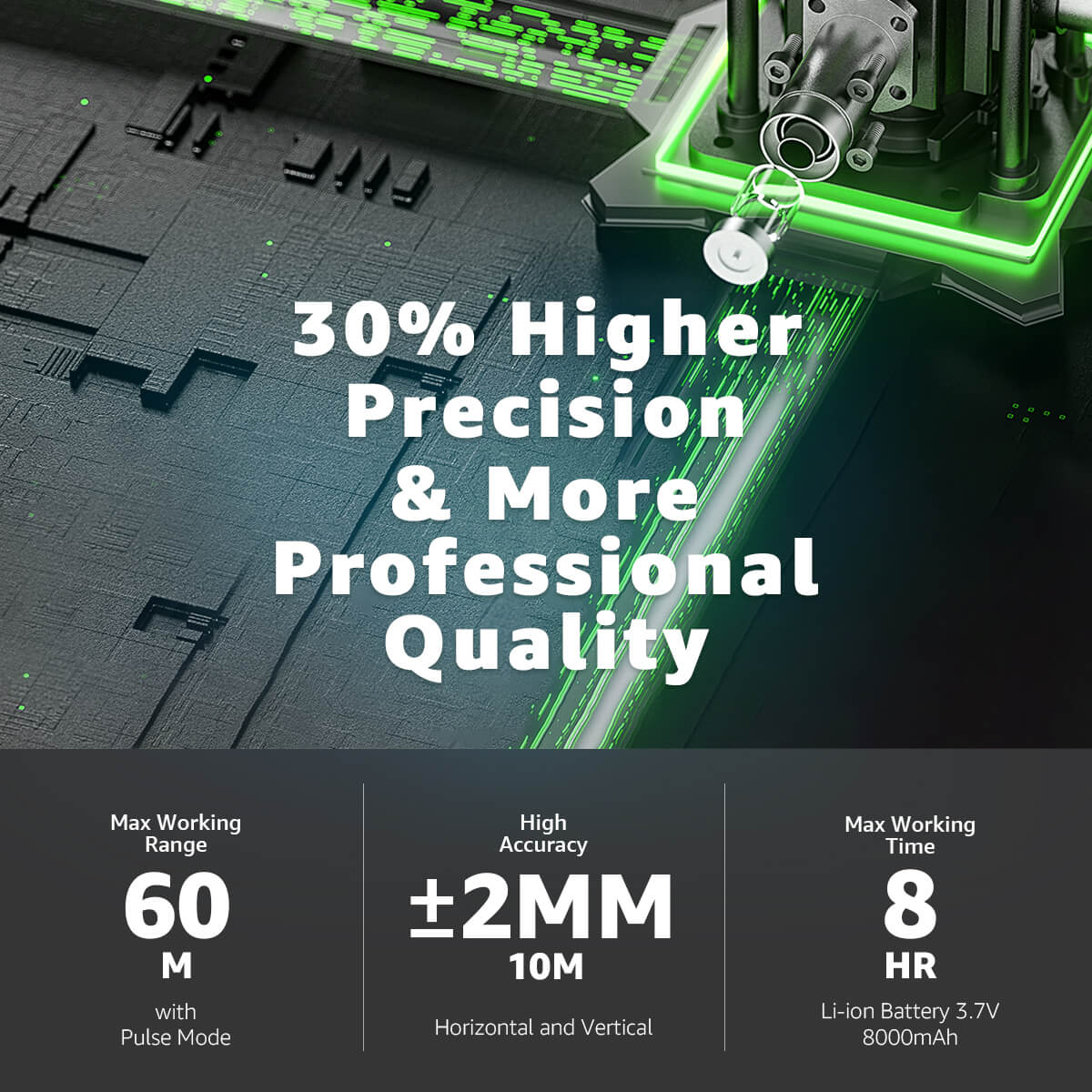

In the high-stakes world of construction, accuracy is key. 3d laser levels provide a leap in precision that's hard to match. They project clear, sharp lines across surfaces. This lets builders align and level structures with ease. Compared to traditional methods, 3D lasers reduce human error. They ensure measurements are spot-on every time. With these tools, tasks like laying out walls, plumbing, and electrical systems are more accurate. This means fewer reworks and a better-built final product. Every line and angle is exact, making high-quality construction the standard.

Time-Saving and Efficiency Benefits

3d laser levels not only enhance precision; they also offer significant time-saving benefits. With faster setups using less manual labor, these tools streamline workflow on-site. Accurate leveling in one go reduces the need for repetitive checks. This cuts down project timelines, boosting overall efficiency. By minimizing errors, they save both time and resources, leading to smoother project management. The instant feedback from a 3D laser level speeds up decision making during construction phases.

Introducing 4D Laser Levels: The Next Dimension in Precision

As construction technology evolves, so do the tools that help us build with precision. Enter 4D laser levels, the advanced sibling of 3d laser levels. Unlike traditional levels that project lines on a singular plane, 4D laser levels cast lines in every direction. This creates a network of reference points in both horizontal and vertical planes, enveloping the job site in a 360-degree framework.

Professionals can now get real-time, accurate spatial data, which reduces the need for manual checks and re-measurements. This new dimension in measurement technology allows for the adjustment of machinery and structures with unparalleled precision, moving beyond the limitations of 2D or 3D projections. 4D laser levels represent a leap towards the future of construction, setting the stage for smarter, more efficient building practices.

Selecting and Operating 3D Laser Levels

How to Choose the Right Laser Level for Your Project

Choosing the right laser level is key for project success. Here are points to consider. First, think about the range you need. Bigger sites need longer ranges. Next, check the level accuracy. It's vital for precise work. See if it's a 3D or 4D laser level. 3D models handle height, width, and depth. 4D adds another level of precision. Check its durability. It should resist dust and water. Lastly, think about battery life. Longer life means less downtime.

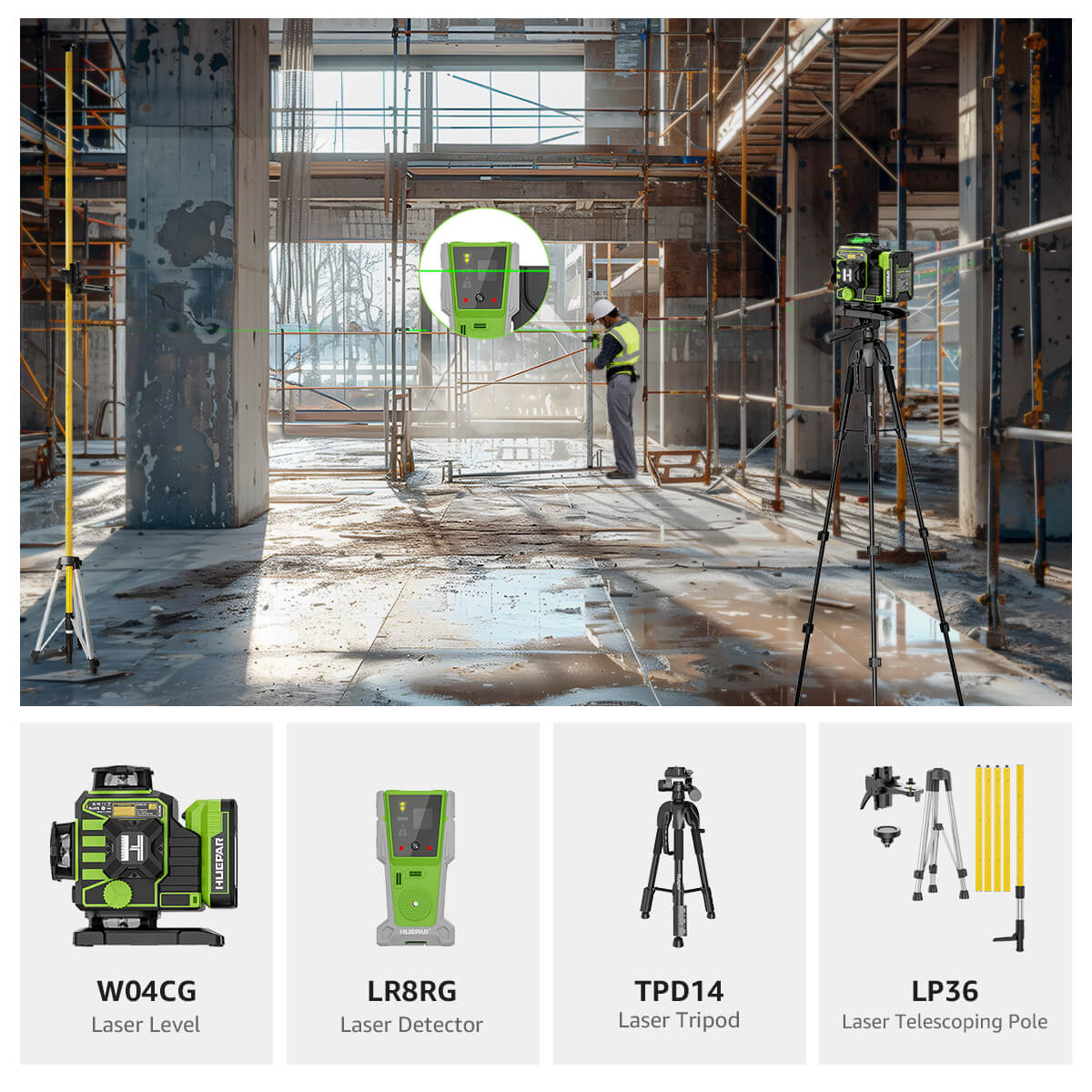

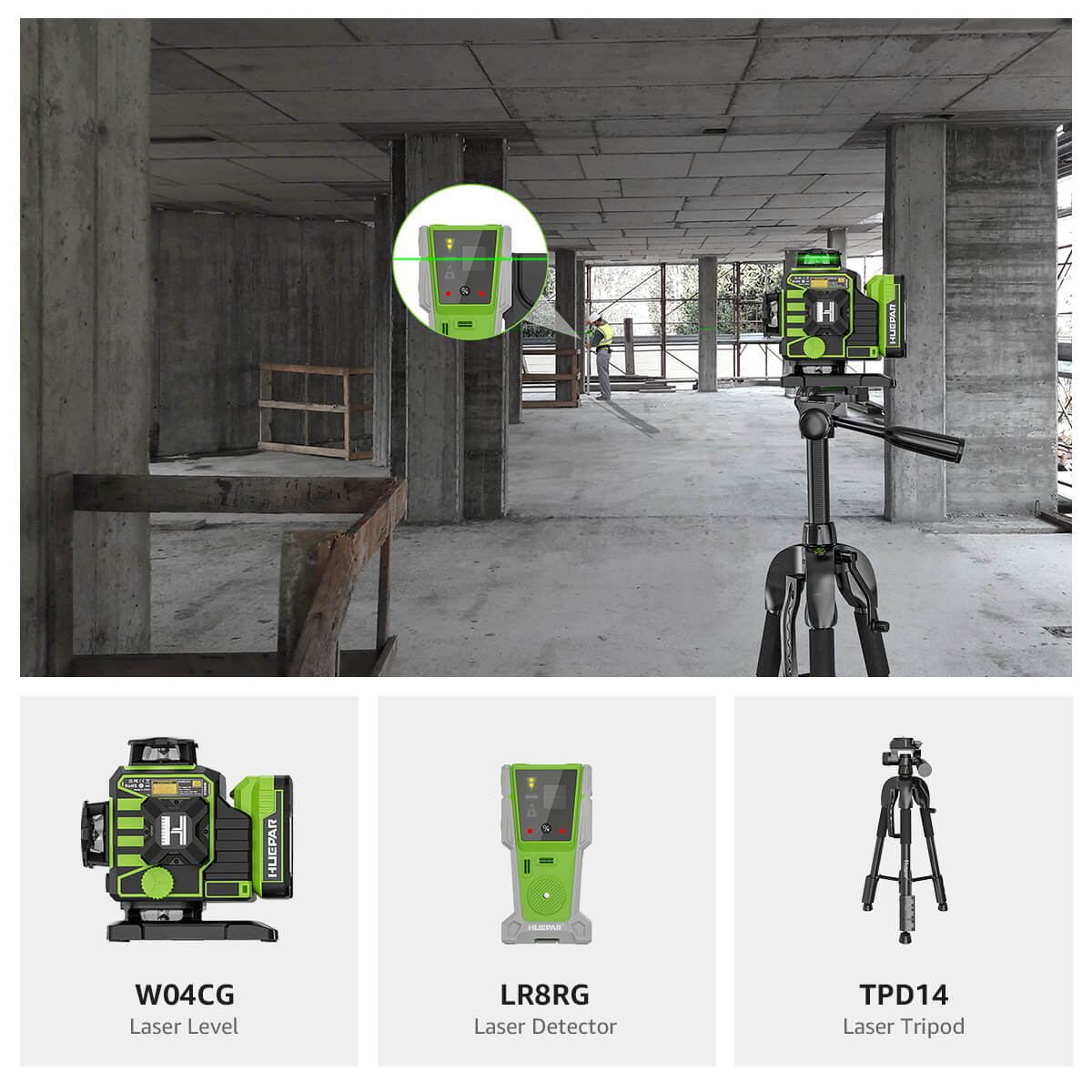

Tips for Setting Up and Using 3D Laser Levels

To properly use 3d laser levels, follow these tips:

- Read the Manual: Before setting up, read the manual to understand your device.

- Calibrate Regularly: Ensure the level is calibrated for precise measurements.

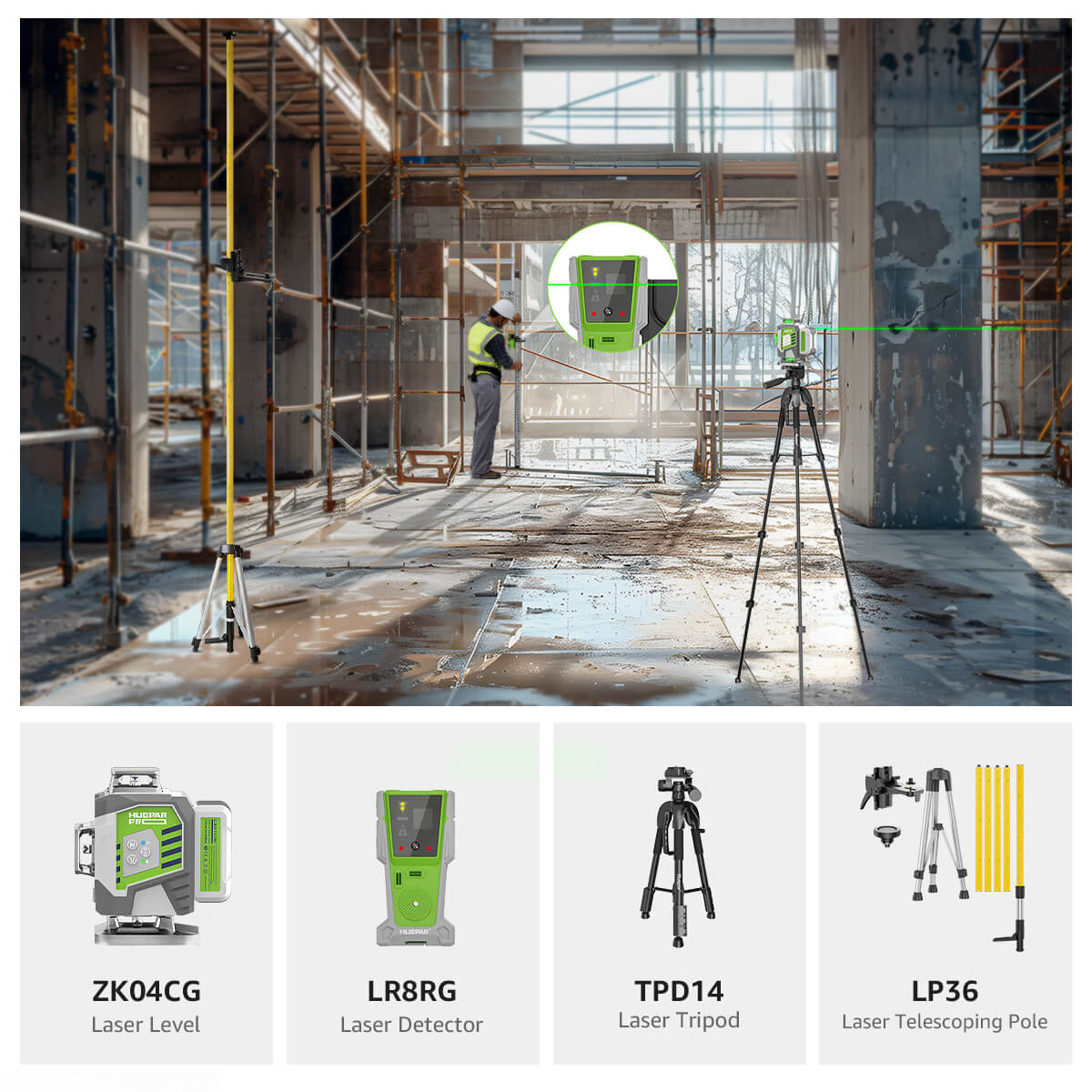

- Secure Mounting: Use a tripod or stable surface to avoid movement during use.

- Clear Line of Sight: Remove any obstructions to ensure an unblocked laser line.

- Check Battery: Before starting, check that the battery is fully charged or has enough life.

- Test Before Use: Perform a quick test to confirm the laser level is working correctly.

- Use Safety Gear: Always wear safety glasses to protect your eyes from laser exposure.

- Adjust as Necessary: Fine-tune the device as needed during your project for consistent accuracy.

Maintenance and Safety Considerations for Laser Levels

To get the most out of 3d laser levels, regular maintenance and proper safety measures are critical. Ensuring devices are clean and stored correctly can prevent damage. Periodic calibration is also necessary to maintain precision. Safety-wise, users should avoid direct eye exposure to the laser, which can be harmful. It's important to follow manufacturer guidelines and wear appropriate safety gear. Regular checks for any signs of damage or wear should also be part of the maintenance routine. By adhering to these considerations, you can extend the lifespan and efficacy of your laser levels.