Unlocking the Potential of 3D Laser Levels in Precision Measurements

What Are 3D Laser Levels and How Do They Work?

Understanding the Basics of 3D Laser Levels

3d laser levels are tools that project beams in three dimensions. They help set out perfect angles and straight lines on all planes. With 3D lasers, users can mark and measure with high accuracy. These tools use diodes to create visible lines on surfaces. This allows for quick and precise alignments. They're ideal for jobs that need exact leveling like fitting tiles or framing walls. 3D laser levels make complex tasks simpler and faster.

The Technology Behind 3D Laser Levels

The tech behind 3d laser levels involves precision optics and electronics. These devices use lasers to cast a 3D grid of lines onto surfaces. This grid helps users align and level objects with high accuracy. Advanced sensors in the levels detect the lines' positions. They ensure the grid is straight, even if the level is not perfectly flat. Some 3D levels also connect to apps. These apps let users control the device and get readings on their phones or tablets.

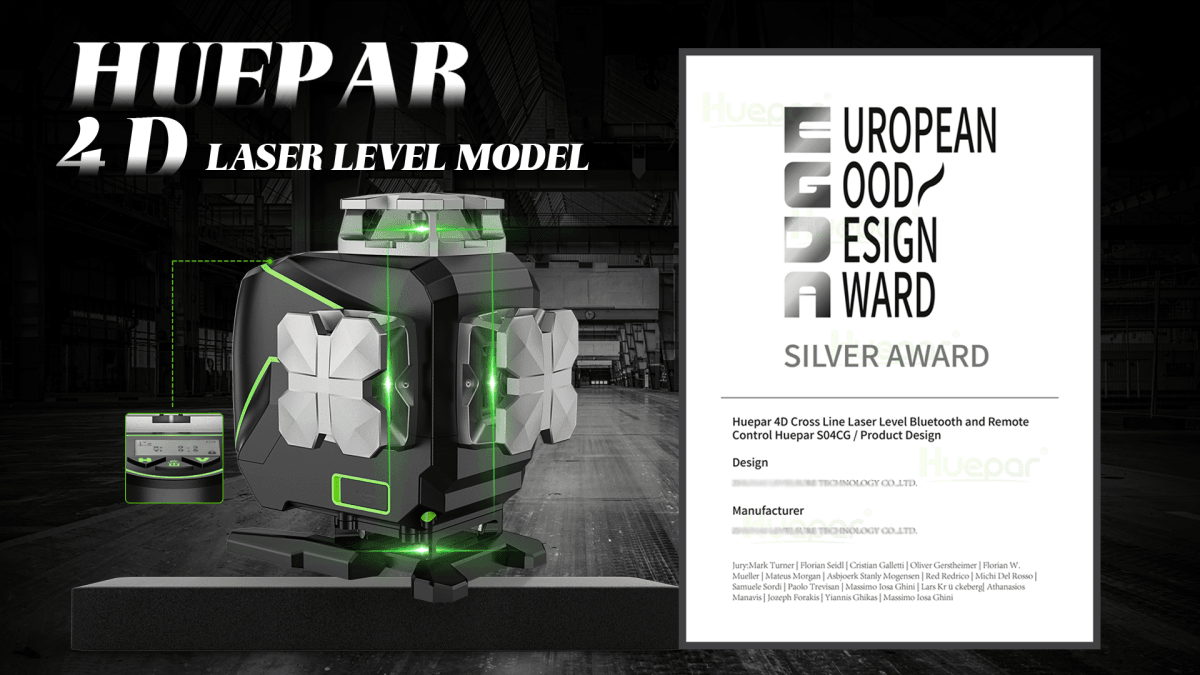

Comparing 3D, Cross Line, and 4D Laser Levels

When choosing the right laser level, you must consider the differences between 3D, Cross Line, and 4D models. 3D laser levels cast beams in three planes, providing 360-degree coverage which is ideal for tasks requiring full-room layout. Cross-line laser levels project intersecting horizontal and vertical lines. They are great for installing tile, cabinets, or trim. 4D laser levels are a step ahead, offering full 360-degree coverage on both horizontal and vertical planes but add a fourth laser plane extending upward. Understanding these key features will help you select the best tool for precision tasks in construction or interior design.

Applications of 3D Laser Levels in Various Industries

Use of 3D Laser Levels in Construction

In the construction industry, 3d laser levels have become invaluable tools. They ensure precision and speed in many tasks. Builders use them to align walls, floors, and ceilings with exactness. They are key in setting foundations straight and true. These levels are great for both indoor and outdoor work. They help install large equipment level and square. Workers trust them for accurate pipe laying and site grading. They are a must-have for any modern construction site.

Benefits of 3D Laser Levels in Manufacturing

3d laser levels have transformed manufacturing with precise alignment and quality control. They ensure parts fit perfectly and cut waste. Checking machinery alignment is fast and safe. This speed saves time and money. 3D laser levels reduce errors in production lines. They make sure every step is right. This accuracy speeds up work and lowers costs. Better precision means high-quality products. Customers trust products that are well-made. Using 3D laser levels means fewer product returns. This increases profits and satisfaction. In summary, 3D laser levels boost manufacturing efficiency and quality.

The Role of Laser Levels in Interior Design and Architecture

3d laser levels have revolutionized the way architects and interior designers work. These precision tools aid in creating accurate, level lines across multiple surfaces. This ensures correctly aligned fixtures like lights or cabinetry. In architectural drafting, 3D lasers provide clear guides for planning and elevation perspectives. For interior design, they ensure symmetry and harmony in room layouts. For complex designs with intricate details, these levels offer invaluable assistance. Interior renovations notably benefit from laser levels for maintaining consistency throughout the space.

Choosing the Right 3D Laser Level for Your Needs

Features to Consider When Selecting a 3D Laser Level

When selecting a 3D laser level, you should consider several key features. First, accuracy is crucial in ensuring precise measurements. Look for a model with a high degree of precision. Second, the laser's visibility is important, especially in well-lit conditions. A bright, clear line is easier to use. Third, consider the device's range. A longer range is beneficial for large-scale projects. Fourth, self-leveling capabilities allow for ease of setup and use. This feature can save time on the job. Lastly, durability and battery life are essential for frequent usage and tough job sites.

Top Brands and Models of 3D Laser Levels

When selecting a 3D laser level, brand and model are crucial. Here are some top picks:

- Dewalt DW089LG - Known for its durability and extended range, it's a favorite among professionals.

- Bosch GLL 3-80 - Offers high precision with its 360-degree coverage and Smart Pendulum System.

- Huepar 603CG - Provides reliable performance with a user-friendly interface, making it great for beginners.

- Spectra Precision LT58 - It stands out for its bright green laser lines, which are easy to see even in well-lit conditions.

- Stabila LA-5P - This is prized for its robust build and accurate lines, suitable for tough job sites.

These models lead in quality and technology, ensuring high precision for a variety of tasks.

Maintenance and Safety Tips for Using Laser Levels

Proper maintenance and safety practices are essential when using 3d laser levels. Here's a list of tips to ensure both the longevity of your device and your personal safety:

- Read the Manual: Always start by reading the user manual thoroughly. It contains specific instructions for your laser level.

- Calibration Checks: Regularly check calibration to maintain accuracy. If the device falls or seems off, re-calibrate it.

- Careful Handling: Handle with care to avoid drops that can misalign the lasers.

- Storage: Store in a padded case when not in use to protect from dust and impact.

- Battery Caution: Remove batteries when not in use for long periods to prevent corrosion.

- Avoid Exposure: Never look directly into the laser beam and do not point it at others.

- Use Tripods: For the best stability, use a tripod designed for laser levels.

- Keep Clean: Keep the laser emitter clean, but avoid harsh cleaning agents that can damage the lens.

- Safety Gear: Wear safety glasses to protect your eyes, especially in bright environments.

- Training: Ensure all users have necessary training to operate the 3D laser level safely.